Features

Energy

Heating

Lighting

Management

Leveraging innovation to reduce energy costs

Opportunities to manage your consumption and support power system reliability

November 17, 2020 By Ontario’s Independent Electricity System Operator

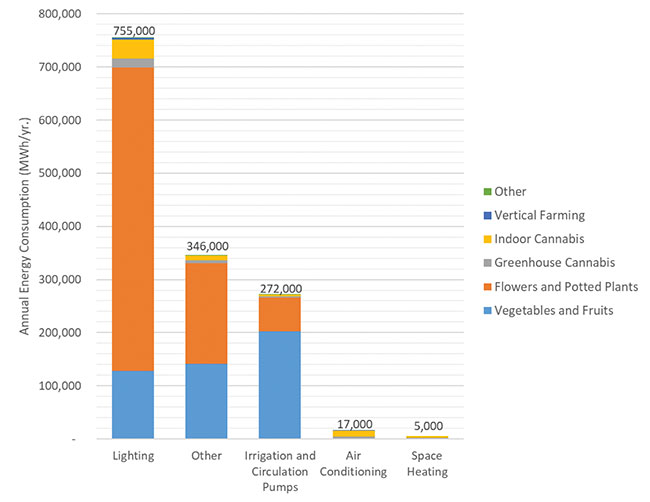

FIGURE 1

Lighting uses more electricity than all other greenhouse end-uses combined, when looking at the greenhouse sector as a whole.

FIGURE 1

Lighting uses more electricity than all other greenhouse end-uses combined, when looking at the greenhouse sector as a whole. As every greenhouse operator knows, growing any type of agricultural product requires the right inputs, the right conditions and the right investments. For the thriving greenhouse sector, controlling energy costs will be a key element of most operators’ growth strategies in the coming years. A reliable, affordable and sustainable supply of electricity has always been important – but never more than now, as the province continues to cope with the economic impacts of COVID-19.

Ensuring access amid rising demand

The greenhouse sector is one of the fastest-growing sources of electricity demand in Ontario. In the Windsor-Essex region of southwest Ontario alone, electricity demand is expected to double over the next five years. Vegetable greenhouses are the largest driver of growth, while cannabis is starting to have an impact as growers ramp up their operations.

Responsible for operating the province’s high-voltage power system and administering the wholesale market, Ontario’s Independent Electricity System Operator (IESO) has been working closely with greenhouse owners and operators to ensure they have access to a reliable supply of electricity, while also helping businesses manage their costs through energy-efficiency programs and funding for innovative projects.

“Affordable and reliable electricity is critical to supporting economic growth,” said Nik Schruder, the IESO’s director of energy efficiency. “In addition to reducing costs for businesses and making them more competitive, energy efficiency also helps us manage increased demand on the grid and defers the need for new transmission investments.”

Save on Energy Retrofit program

Energy-efficiency programs under the IESO’s Save on Energy brand have enabled businesses to reap the operational and financial benefits of newer, more energy-efficient equipment. For greenhouse operators, the Save on Energy Retrofit program delivers the greatest bang for the buck. It supports projects and upgrades that provide sustainable, measurable and verifiable reductions in peak electricity demand and consumption, including:

- lighting controls and retrofits

- heating, ventilation and air conditioning (HVAC) redesign

- chiller replacement

- variable-speed drives

- building envelope improvements, including insulation, window glazing and roof barriers

Lighting uses more electricity than all other greenhouse end-uses combined.

Traditional high-intensity discharge lighting, with double-ended high-pressure sodium (DE-HPS) grow lights, are increasingly being replaced with high-efficiency LED lighting. LED lighting uses up to 50 per cent less energy than HPS lights. It also lasts between five and 10 times longer than DE-HPS, cutting down on replacement costs. In many cases, greenhouse operators who invest in energy-efficient LED lighting see a payback within two to three years.

In addition to customizing spectral light to suit the crop or the growth stage, LEDs also run cooler than traditional lighting technologies, resulting in less waste heat and lowering the demands placed on HVAC equipment – potentially leading to even more energy savings.

Dehumidification, which requires mechanical cooling, can also drive up energy use. Installing variable frequency drives on exhaust fans, heat buffering systems, zone pumps and mixing valves can deliver significant savings by controlling the speed of motor-driven equipment so it doesn’t use energy unnecessarily.

Grid Innovation Fund

With more than 1,300 megawatts of Ontario greenhouse load seeking to connect to the grid by 2025, the province’s infrastructure is facing significant increases in demand for electricity. To manage this, the IESO’s Grid Innovation Fund (GIF) financially supports innovative projects that either enable customers to better manage their energy consumption or that reduce the costs associated with maintaining reliable operation of the province’s grid. Since 2005, the GIF has provided financial support to more than 200 innovative energy projects across the province.

In November 2019, the GIF issued a targeted call for novel projects focused on reducing electricity demand from indoor agriculture during local and bulk system peak periods. With up to $2.5 million available in total for approved projects, applications represented a broad range of technologies and solutions, including energy management, load curtailment, dynamic voltage controllers, microgrids, artificial intelligence, lighting, program design, HVAC and electrolyzer research.

One of the successful proponents was a partnership between Allegro Acres, Harrow Research and Development Centre, the University of Windsor, Red Sun Farms and Sollum Technologies. They are piloting a project to evaluate the performance of low-intensity LED lighting and controls used over a 24-hour period against the current practice of using high-intensity HPS lighting over a 16- to 17-hour period. This new approach to lighting has the potential to reduce electricity consumption by 15 to 33 per cent, while maintaining or improving crop growth and yield.

“Testing and implementing sustainable agricultural practices has always been a high priority at Allegro,” said Gene Ingratta, president of Allegro Acres. “With the growing demand for locally produced food, this project was the perfect opportunity to really make a difference in the supply chain. For this pilot project, we intend to reduce light pollution and our carbon footprint while managing the strain on the electricity grid with Sollum’s fully dynamic LED lighting system. Now, for the first time ever, we’ll be able to supply our customers with year-round, locally grown Canadian peppers.”

Another successful application was from Great Lakes Greenhouses in Leamington, who will be involved in developing an artificial intelligence (AI)-powered program that uses data and a learning algorithm to increase energy efficiency without reducing crop yield in large-scale commercial greenhouses.

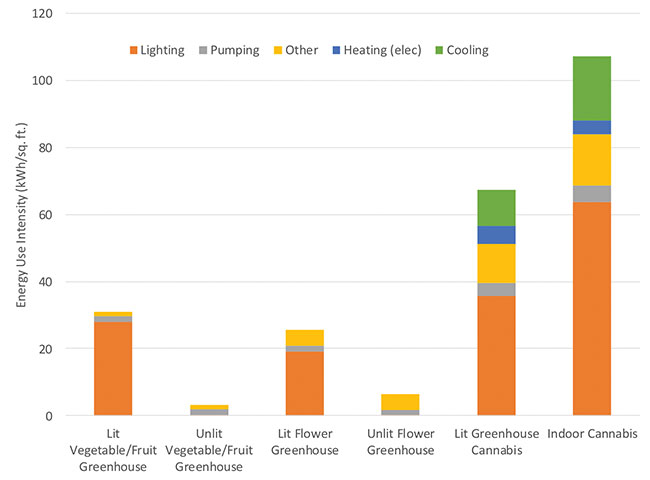

FIGURE 2

A lit vegetable greenhouse uses 10 times more electricity than an unlit one. Electricity consumption is expected to increase by 280 per cent from 2018 to 2024. Consumption related to cannabis growth is projected to increase 1,253 per cent by 2024 as a result of new greenhouses and indoor facilities.

Voice your needs

It is important that greenhouse operators and their respective communities have input into electricity decisions, voicing their electricity needs as well as their preferred solutions. Ontario’s greenhouse operators can join Regional Electricity Networks to hear first-hand about issues or innovations impacting the province’s electricity sector, and to provide input into future electricity planning in their communities. For more information, visit http://www.ieso.ca/Get-Involved/Regional-Planning/Electricity-Networks/Overview.

Although recovering from the economic damage resulting from the pandemic will take time, greenhouse owners and operators have options. Energy-efficiency and demand-management programs, plus other forms of energy innovation, can help reduce operating costs and boost bottom lines. Need guidance? Contact the IESO and/or your local distribution company for additional information. We’re here to help.

Photo credit: G. Ingratta

First to produce winter lit peppers

Starting in November, family-owned Allegro Acres will be implementing Sollum Technologies’ smart LED lighting. This makes Allegro the first Canadian commercial greenhouse producer to grow peppers under lights in the winter.

Manufactured in Montréal, Que., Sollum says the key to their patented smart lighting technology is the cloud-based SUN as a Service platform, which uses the fixture’s capacity to recreate, perfect and modulate the full spectrum of the sun’s natural light. As a result, it is said to reproduce Southern Australia’s light cycle just as it can do for Northern France’s light, which enables the cultivation of fruit or vegetables regardless of its native climate and the location of the greenhouse.

Beginning with four acres this year, Allegro will be working with Harrow Research and Development Centre to test and further develop lighting recipes and regimens for optimizing pepper growth.

Ontario’s Independent Electricity System Operator (IESO) works at the heart of the province’s power system ensuring there is enough power to keep the lights on, today and into the future. Find out more at ieso.ca

Print this page