Features

Biocontrols

Inputs

Friends with benefits: Biopesticides and biostimulants

What are biopesticides and biostimulants? By choosing the right products and applying them in the right situations, microbial bioproducts could be used to strengthen your biocontrol program.

March 4, 2019 By Dr. Michael Brownbridge

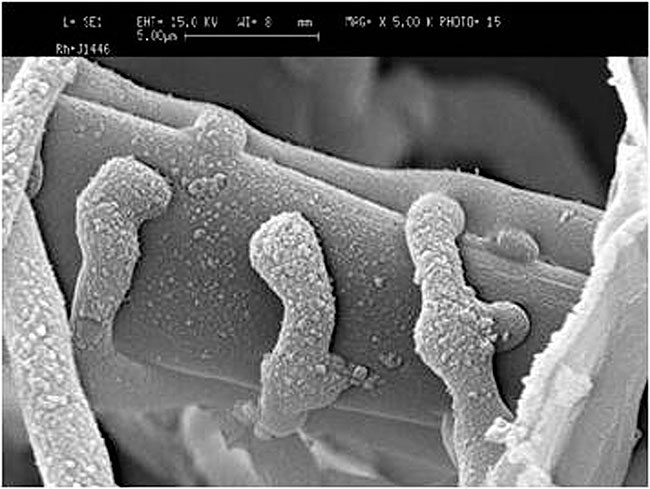

FIGURE 1. Gliocladium catenulatum (active in Prestop) parasitizing a fungal strand of Rhizoctonia solani. Photo credit: Lallemand Plant Care

FIGURE 1. Gliocladium catenulatum (active in Prestop) parasitizing a fungal strand of Rhizoctonia solani. Photo credit: Lallemand Plant CareAs a grower, it’s important to think about ways in which your biocontrol programs can be strengthened. There is an increasing number of biopesticides and a staggering array of biostimulants available on the market.

The trick is figuring out which of these materials to use, where and how to integrate them effectively and efficiently into the production system to benefit pest and disease management strategies, as well as meeting other production challenges. This article focuses on microbial bioproducts, and considers ways in which these materials can become valuable allies in crop production.

What are biopesticides?

According to Agriculture and Agri-Food Canada, biopesticides are ‘pest management agents and chemicals derived from natural sources such as microorganisms, plants, animals and minerals.’ They are actively applied to manage pests, weeds or diseases, and because these claims are on the product label, efficacy data needs to be provided to the Pest Management Regulatory Agency (PMRA) as part of the registration process. Their unique modes of action help mitigate resistance, while being very safe for applicators, workers and the environment, and deliver to consumer/market demands around sustainability. Moreover, they are typically compatible with natural enemies, which makes them excellent companion products in biocontrol programs. Most have short REIs and PHIs, so they have minimal impact on routine crop management activities. In Canada, biopesticides fall into three groups:

- Microbial: contain living microorganisms and associated metabolites (or by-products).

- Semiochemicals: cause a desired behavioural response in a target organism, e.g. insect sex pheromones or aggregation pheromones, which are used in monitoring traps.

- Non-conventional pest control products: includes plant extracts and oils, mineral oils, and other materials that are commonly available and known to have pesticidal effects, e.g. vinegar.

Among these groups, microbial biopesticides are probably the best known and most widely used. Predominantly based on bacteria, fungi and viruses, they contain living microorganisms so they have to be stored and applied in ways that preserve their viability. Several products contain microbes with the same or similar names, but that doesn’t mean they all have the same spectrum or level of activity. For example, BotaniGard (BioWorks Inc.), BioCeres (Anatis Bioprotection) and Velifer (BASF Corp.) all contain Beauveria bassiana as the active ingredient, but are based on three different isolates of the fungus. It’s important to select the right tool for the job and, depending on the disease or pest being targeted, ensure that they are directed to the site of infection or infestation.

Microbial biopesticides in IPM

Generally, biopesticides are applied as foliar sprays or to the substrate. They are functionally compatible with other biocontrol agents and often highly complementary. In chrysanthemums, for example, bioinsecticides such as BotaniGard are routinely used together with insect-parasitic nematodes and foliar and soil-dwelling predatory mites to control thrips. Good spray practices are critical to efficacy. Hydraulic sprayers, when used to apply fine spray mists rather than a heavy wet spray, can provide excellent coverage of upper and lower leaf surfaces. Automated low volume mist (LVM) sprayers like Dramm’s AutoFOG can also be used to apply bioinsecticides and will give similar levels of leaf coverage.

Microbial biopesticides for disease control can have several modes of action:

- Antagonism: metabolites produced by the growing microbes will kill or inhibit growth of pathogenic microorganisms.

- Predation/parasitism: the microbe literally attacks or parasitizes the pathogen; fungi like Gliocladium (Prestop) and Trichoderma (RootShield) can do this.

- Competition: these organisms colonize the root surface, using plant root exudates as nutrients, and outcompete pathogens for living space and nutrients.

- Induced resistance: microbes produce molecules which activate a plant’s natural defences.

Biofungicides often have more than one mode of action which contributes to the control or suppression of diseases and may confer other plant benefits as they colonize the root surface. Some Trichoderma and Bacillus species/isolates, for example, also produce phytohormones which enhance root development, or form biofilms over the root surface, which enhance plant resilience to drought. In this respect, they also perform biostimulant functions.

The most recent addition to the biofungicide arsenal are materials that induce plant defense mechanisms. LifeGard (Certis USA), is a foliar-applied biological plant activator that triggers an induced resistance (IR) response in plants. Based on a naturally occurring bacterium, Bacillus mycoides, the organism has no direct effect on plant pathogens. Rather, it activates or induces the plant’s innate defenses so that the plant protects itself against infection. It is not a curative treatment, but is applied to prevent disease development. Although it is not registered for greenhouse crops, this mode of action is probably representative of what we can expect in many next generation biofungicides and bioinsecticides.

The value proposition presented by biopesticides in greenhouse production lies in their compatibility with other natural enemies. Applied at strategic points in a production cycle, they complement the activity of other biocontrol agents, allowing some crops to be managed ‘biologically’ from start to finish. Using chrysanthemums as an example (see infographic), a bioinsecticide dip can be used to clean up thrips on incoming cuttings, a biofungicide can be applied to the growing medium to protect against soil-borne pathogens, and bioinsecticide sprays can support the bioprogram later in the growing cycle.

What are biostimulants?

The term biostimulants incorporates a diverse group of product technologies and includes microbial inoculants, biochemical materials, amino acids, humic acids, fulvic acids, seaweed extracts and more. They are sold on the promise of bringing multiple benefits to the crop they are applied to. In a nutshell, they promise to improve overall plant health and resilience, which enhances productivity. They carry no claims around pest or disease control, so they are not regulated by the PMRA – yet.

The promise (and challenges) of biostimulants

There is a large number of products sold as ‘crop boosters’ or ‘enhancers’, so which do you choose? Particularly when you may not actually see significant and measurable benefits in what may be considered a normal growing year, or in hydroponic systems where plants are provided with all the nutrients they need. Also in many cases, the instructions for use are often vague or incomplete.

Different biostimulants can induce different plant responses, and effects are influenced by the timing of application, plant species/cultivar, plant growth stage, soil or substrate type, management practices (inputs) and environmental factors. The benefits may only be observed when plants are under stress. Understanding the interactions between biostimulants, plants and the environment is essential to realizing the promise offered by these materials.

Field data obtained from multi-locational trials of microbial biostimulants provide insights to the potential value these products can bring to greenhouse horticulture. Synergro from Concentric Ag contains a consortium of microbes. Its use in the production of organic field tomatoes increased yields, and levels of nitrogen in tomato leaf tissue were higher in treated plants, suggesting that applications of the product may improve uptake or plant access to this critical macronutrient. In field-grown lettuce, use of the product resulted in a 4.5 per cent yield increase and a reduction in culls (i.e. more marketable produce) under standard fertilization rates. The trial also showed how using this product enabled reductions in nitrogen inputs to be made without significantly compromising yield. This is significant for jurisdictions where there are strict regulations around nitrogen leaching and runoff; a slight reduction in yield may be an acceptable trade-off to conform to environmental regulations.

RELATED

- The right way to apply microbial biopesticides

- Friendly but deadly: Getting to know your mycoinsecticides

- Designing your greenhouse IPM program

The plant growth promoting rhizobacterium (PGPR) Bacillus amyloliquefaciens strain IT45 (soon to be marketed in North America under a new trade name of “LALRISE Start Vitae-YE” [formerly Rhizocell]; Lallemand Plant Care) colonizes the rhizosphere (the area surrounding plant roots) using root exudates as nutrients. As bacterial communities develop on the root surface they secrete a mucilaginous coating, or biofilm, comprised of proteins, complex sugars (polysaccharides) and nucleic acids. The biofilm helps maintain the integrity of the bacterial communities on the roots, and also benefits the plant by providing a buffer against environmental stress factors and desiccation. Consequently, plants are better able to tolerate periods of water stress or drought. In addition, the bacterium solubilizes soil-bound phosphorous and chelates minerals such as iron, enabling better uptake. It also produces phytohormones that stimulate root development. The biostimulant has been tested in a wide variety of field crops; in all cases, there were yield benefits in the range of 6 to 10 per cent.

Although biostimulants may be used at different points in the production cycle to achieve different goals, a common outcome is more uniform crop development and enhanced yield. Essentially, these materials improve plant health and resilience, so plants invest less energy dealing with stressful conditions and additional energy can go into production. Clearly, we still have more questions than answers around the role biostimulants can play in greenhouse crops, but considering the significant benefits obtained in field crops, there is a tremendous opportunity to capture this potential in greenhouse production.

Michael Brownbridge, PhD, is the research director for horticultural production systems at Vineland Research and Innovation Centre. This work was funded in part by the Canadian Agricultural Partnership.

Print this page