The selling price of any greenhouse

horticulture product has remained the same, more or less, for the past

20 years. This has been the case despite the fact many major production

inputs have increased dramatically

The selling price of any greenhouse horticulture product has remained the same, more or less, for the past 20 years. This has been the case despite the fact many major production inputs have increased dramatically.

The selling price of any greenhouse horticulture product has remained the same, more or less, for the past 20 years. This has been the case despite the fact many major production inputs have increased dramatically.

Here are some examples:

Labour, up 40 per cent.

Greenhouse structures, up 30 per cent.

Plant material (seed, bulbs, rooted cuttings), up 30 to 50 per cent.

Equipment (sprayers, computers, etc.), up 50 per cent.

Chemicals, up 100 per cent.

Fertilizers, up 50 per cent.

Packaging and labelling, up 400 per cent.

Extra labour for getting product ready for market, up 400 per cent.

Transportation, up 100 per cent.

And last, but not least, energy costs, up 150 to 200 per cent.

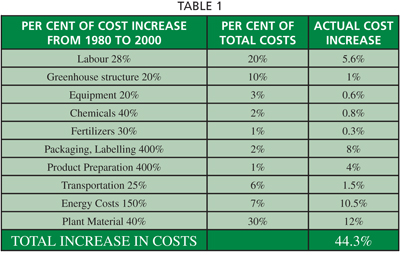

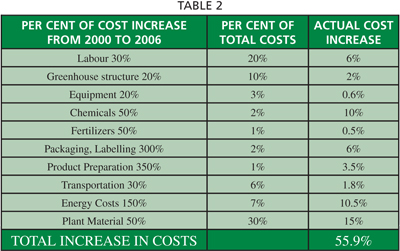

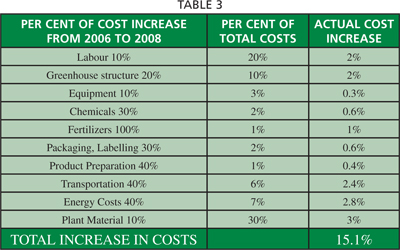

Those figures represent the years from 1980 to 2000 (Table 1 ) a span of 20 years. The scary part is that from 2000 until 2006, the cost again increased by 55.9 per cent (Table 2 ). From 2006 until 2008, there was another increase of 15.1 per cent (Table 3 ).

As you can see from the charts, there is a total increase of 115.3 per cent in costs, yet no change in the selling price. How can a greenhouse operation survive?

In order to combat all of these increases in costs for the past 28 years, growers have had to become more efficient. They have done this in several ways. For example:

More efficient use of space.

Reducing shrinkage.

Structural improvements.

Increasing production per square foot.

Labour efficiency through mechanization.

Adopting improved production techniques.

Product mix.

Finding new or different markets, or both.

Larger growing areas.

Hard work.

Through these various factors, growers survived and made a living until the last cost increase, namely energy costs. The cost of fuel increased dramatically, about 180 per cent, and without warning. This is an increase of 18 per cent of the total costs. Growers didn’t have time to make adjustments in order to compensate for this increase. We have to remember that all the other costs we mentioned are not at a standstill. We still have to keep improving in order to stay where we are. However, this latest increase of 18 per cent has to be passed on to the consumer.

If we calculate inflation at only two per cent per year, which is a very low estimate, in addition to the other ongoing cost increases, then growers need a 100 per cent increase in selling prices just to stay within inflation increases over the past two and half decades. The consumer, however, won’t stand for such a large increase in just one season.

In addition, there are some practical things you can do to help combat rising energy costs.

Before we even tackle energy conservation, it’s vital to calculate your production and operation costs. This is more important now than ever. Wise decisions can only be made from facts and real numbers, and they do vary between one greenhouse operation and another. Having said that, there are some ways that you can stretch your BTUs:

A. Try to use your heated greenhouse space more effective by:

Double spacing.

Using larger liners, so you can delay planting into the final container.

Check whether growing your own plugs, taking your own cutting, or other starting material is effective, or if you should order them.

Crop production management, e.g., starting your poinsettia crop earlier when heating costs are not high will enable you to finish the crop at much cooler temperatures.

B. Check heat source efficiency.

C. If you have double-poly greenhouses, the most important thing for heat retention is to have the plastic fully inflated, because the air between the two plastic layers is the insulation media.

D. Many obvious solutions are still being overlooked, for example:

Put doors between different temperature compartments.

Propagation areas should be away from the warehouse, where doors are constantly being opened and closed for shipping and receiving. If the propagation area cannot be moved away from the warehouse, then a well-insulated door must separate these two areas.

Fans must have insulated shutters that close properly.

Don’t set the humidity too low during the winter or during cold weather, because that will cause the heating and the ventilation system to activate at the same time.

E. Irrigation water temperature should be at least the same as the air or media temperature you are trying to achieve.

F. Put your sensor where the crop is not higher or lower, because temperatures might vary up to 7ºC between the floor level and the hanging basket level.

G. Condensation on plastic or glass should be minimized as much as possible, because the condensation will cut light transmission, which results in lost energy.

H. Energy curtains are essential for glass houses since the heat loss is greater than in plastic houses. However, heat curtains are beneficial for plastic houses too.

I. Whatever the cost of energy, do not compromise on crop requirements. Inferior crop quality is never justified because customers will not pay for sick plants, but they will pay more for a quality product.

The solution to this latest energy crisis and other costs is very simple:

Prices have to increase by 20 to 30 per cent, at a minimum.

As stated earlier, consumers won’t tolerate a 100 per cent increase, but a 20-30 per cent hike is acceptable for them and essential for you.

Growers must strive to give better service and a higher quality product, while the retailer must keep plants alive and in good condition so that the customer will not be cheated when the purchase is made. No customer buys plants in bulk, like toilet paper, just because they’re

on sale. Customers buy for beauty and enjoyment, and a $2 or $3 cost increase will never stop them from buying flowers. However, inferior plants will definitely kill every sale.

If you are a plant producer and don’t increase your prices this season, then don’t cry down the road when you are struggling to meet your mortgage payments. This increase is not a luxury for a better profit margin, but is necessary for the survival of your operation. Those who make the necessary increases will remain viable, but those who don’t will slowly, but surely, disappear from the greenhouse scene.

I work with many growers of different sizes. The common factor for survival and progress in any greenhouse operation is to adjust to the needs of the consumer. They must communicate that need to buyers and tell them what is required to make it happen from the aspects of programming. They must sell the plants at a cost that will enable the grower to produce at a profitable margin and also provide the buyer with a reasonable mark-up.

The floriculture sector of horticulture has some of the few products that still signify enjoyment and beauty; let us not make it ugly.

Melhem Sawaya of Focus Greenhouse Management is a consultant and research coordinator to the horticultural industry. Comments on this or any other article are always welcome by e-mailing me at

focussawaya@kwic.com.

Print this page