Features

Growing Media

10 things to know about growing in wood substrates

Answers to the most frequently asked questions on incorporating wood products.

December 18, 2020 By Dr. Brian E. Jackson

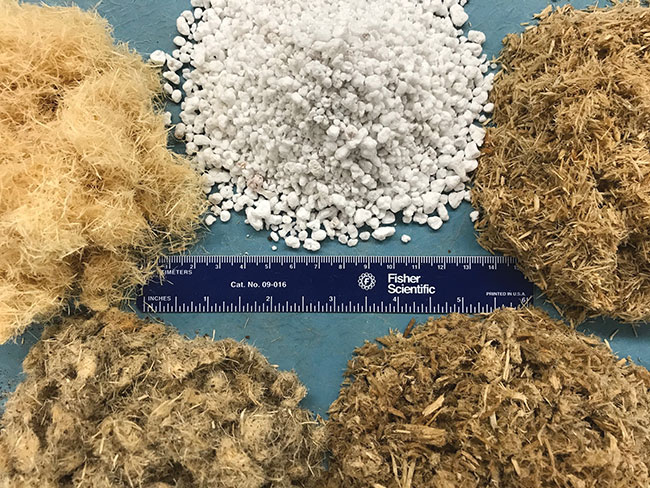

Traditionally, perlite (top center) has been the main component amended with peat to create substrates, but wood products are now commonly used in mix creation. ALL Photos: B.E. Jackson

Traditionally, perlite (top center) has been the main component amended with peat to create substrates, but wood products are now commonly used in mix creation. ALL Photos: B.E. Jackson With change comes challenges, or at least modifications, particularly when growers consider switching to soilless substrates containing wood products. Over the past 15 years of research on wood substrates, plus countless interactions with substrate manufacturers and growers, I am often asked a similar set of questions. Here are some that I encounter most often:

1) Will wood substrates tie up nutrients and cause nutrient deficiencies? Research has shown that microbial populations are higher in substrates containing fresh wood products (mostly due to higher carbon content) and those microbes are indeed immobilizing nitrogen. However, the good news is that the severity of nitrogen microbial immobilization is not as high (or insurmountable) as once thought or feared. This greatly depends on the wood product’s particle size, its processing and preconditioning, as well as the length of time it remains in a container during subsequent production. Nitrogen immobilization issues are also dependent on the percentage of wood added to substrates. Many researchers and growers have found that 20% wood incorporation (in peat) leads to little change in available nitrogen. Above that percentage, and depending on the type and age of the wood, nitrogen can become limited.

Microbes in wood substrates will immobilize nitrogen as well as sulfur and some phosphorus to lesser extents, but so do other organic substrates, just in lower amounts. Growers who naturally fertilize their crops at lower levels (i.e. 75 to 90 ppm nitrogen) and switch to a mix with over 20% wood will most certainly see some nutrient deficiencies depending on the crops being grown. However, growers who customarily fertigate at higher rates (i.e. 150 ppm) will likely see no change in their crops. In short, the particle size of the wood materials and the percentage incorporated will dictate the rate and extent of nutrient tie-up. The economics of wood components often outweigh the cost of extra fertilizer if/when needed.

2) Are wood substrates toxic to plants? If wood products have not been aged, treated, or processed in machinery that allows chemicals in fresh/green wood to be removed (solubilized or volatilized), then there can be issues with seed germination and/or severe plant stunting. The majority of reported issues have been with freshly produced, hammer-milled pine wood substrates. Commercial products on the market today have not had these problems widely reported.

3) Are there changes to substrate pH? Wood has an inherently high pH compared to peat moss or pine bark. When you replace a fraction of those materials with wood, you increase the percentage of a higher pH material while decreasing the percentage of a lower pH material. Coupled with the lower pH buffering capacity of wood, this can quickly shift the pH upwards. Growers using less than 40% wood in their substrates should not notice a drastic change in pH, however, it should be monitored regularly. Lime amendment rates could be lowered as the percentage of wood increases.

4) Will wood substrates decompose in the pot and affect my crop? There is little evidence to suggest that wood substrates will degrade during the production time of most any crop. However, this depends on the wood type and species. If growers are making/using their own wood materials that contain hardwood or sawdust, there can be negative issues with substrate decomposition, discolouring, and shrinkage. Commercial products on the market today are made from pine, fir, or spruce, which are species known to be highly resistant to decay.

5) Should plants grown in substrates containing wood products be irrigated in the same way? For some growers, one of the biggest learning curves has been in adjusting irrigation practices for mixes with more than 20% wood product. Properties of the mix will affect how water is held, moved and released, and this will change with the percentage and type of wood fiber being incorporated. The grade of peat has an impact as well. As a result, some growers say their mixes hold more water, while others say less. It should not be assumed that mixes containing wood will behave like peat-lite mixes. The most notable difference may be the increased surface drying that occurs in wood mixes. This can cause some growers to irrigate when, in reality, there is still plenty of water left in the pot.

6) Can wood substrates be used with existing pot-filling equipment and protocols? Most reported challenges have involved substrates containing more than 20% disc-refined wood fibers. The higher the incorporation rate into peat, the “fluffier” the substrate becomes. This can create challenges for growers using certain flat/pot-filling machines, especially as the container size gets smaller. Growers and substrate suppliers have found several solutions: adjusting the moisture of the mix before potting, over-filling the pots, vibrating tables/conveyers to settle the mix, or using other practical methods to ensure adequate fill. Wood fiber properties and container sizes are the two biggest variables that can influence pot filling.

7) Do PGR’s work the same way on crops grown in wood substrates? Several research trials have shown no significant changes in plant growth response to PGR drenches when grown in substrates amended with up to 50% wood. Of course, this may not be true for all PGR products and formulations or for all wood products, especially when used at higher incorporation rates above 50%. Growers have generally been successful with numerous crops treated with PGRs while using substrates with wood products.

8) If I blend wood with peat moss, will the volume of the final mix be the same? It depends, but likely not. When two or more substrate components (raw materials) are blended together, the end volume will often be lower than expected. It depends on the density of the materials, as well as the particle size, shape, and inherent characteristics. Depending on the type of wood product being blended, as well as the method of blending, the final product/mix yield will decrease. In other words, 1 + 1 will likely yield 1.6 to 1.9 and not 2.0. Wood materials made with hammer mills are the easiest to blend, while disc-refined products are the most difficult. Buying premixed products avoids this issue.

9) Are there any consistency issues with commercial wood substrates? Few if any. Different manufacturing methods used to create different wood products offer varying product sizes, shapes, and qualities. At present, the most consistent wood materials are disc-refined or extruded. Though materials made by hammer mills (pine tree substrates, for example) can be made with a high degree of precision and reproducibility, less is known about how to achieve the same consistency on a commercial scale. It is believed that with further research on hammer-mill processing of pine, these products can have the same consistency and reproducibility of other manufacturing methods. This could be important as hammer-milled wood materials are cheaper to produce compared to extruded and disc-refined methods.

10) Which is the best commercial wood substrate product on the market? Whichever one you choose. Of the commercial products available as 100% raw wood material or as pre-blended mixes, suppliers across North America have ensured that these products are uniform and ready for use. Having worked with nearly all, if not all, wood materials on the market today, I know there are differences in how the materials behave, but they can all be used successfully by tweaking production practices. Purchasing a product that fits your operation (existing machinery, pot size, irrigation system, etc.) from a reputable substrate supplier is a key decision to be made.

We may not yet fully understand all of the challenges and potentials of using wood substrate materials in our growing systems, but we know more now than we did at the start 15 years ago. Grower experiences coupled with independent research results will continue to answer these questions as well as others that arise in the future.

Brian E. Jackson, PhD, is an Associate Professor and Director of the Horticultural Substrates Laboratory at NC State University. Brian can be reached at Brian_Jackson@ncsu.edu.

Print this page