Year-round, high-wire production of mini-cucumbers with supplemental

lighting is being fine-tuned at the Greenhouse and Processing Crops

Research Centre.

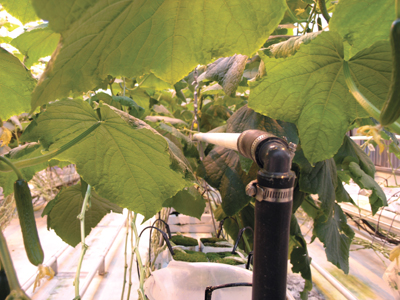

Year-round, high-wire production of mini-cucumbers with supplemental lighting is being fine-tuned at the Greenhouse and Processing Crops Research Centre.

|

|

| Dr. Xiuming Hao, with a mini-cucumber crop on raised troughs under supplemental lighting. Advertisement

|

Dr. Xiuming Hao previously worked with high-wire, long English cucumber production with supplemental lighting. The results were most impressive, with yields of between 280 and 300 cucumbers per square metre per year – about double that of traditional growing systems.

Mini-cucumbers should also respond quite well to supplemental lighting, and a mid-April tour through a pair of five-month-old crops – one with supplemental lighting, the other the control – clearly illustrated the difference. The “lit” crop was much more robust, with significantly more fruit.

“It has not required any sprays,” adds Hao. “The plants grow so well and the yields are quite high.”

|

|

| Grow pipe canopy heating.

|

Mini-cucumbers may have even more potential to benefit from high-wire production with supplemental lighting. Stem growth is slower than with long English cucumbers, meaning growers won’t have to de-leaf or lower the crop as often.

“There is at least one mini-cucumber grower in the Leamington area who is in year-round production with supplemental lighting.”

One of the main reasons for moving into year-round production of any greenhouse crop is to maintain markets. In Canada, it’s hard to grow through the winter, unless supplemental lighting is used. Even if you have additional costs with winter production, such as with heating and lighting, “you will be able to maintain your business relationships with your customers.” Growers will have sales “when prices are quite high.”

For greenhouse vegetable consumers, it means a quality product year-round.

Hao’s work with the mini-cucumbers is particularly focused on grow pipe utilization, different nutrition formulas, and the use of LEDs to improve light quality.

|

|

| Dr. Xiuming Hao checks a fruit growth sensor measuring fruit diameter changes. Data is being collected to develop a relationship model between fruit growth and fruit temperature.

|

Calcium deficiency is believed to be related to leaf chlorosis under supplementary lighting. The study found that a high concentration of calcium reduced leaf chlorosis and increased fruit yield.

Adding the blue LED lights alleviated leaf chlorosis symptoms but did not increase fruit yields in comparison to HPS lighting alone; ambient solar radiation might be supplying sufficient blue light on its own.

The grow pipe increased leaf and fruit temperatures, along with fruit yield. Very little was known about grow pipe heating in cucumber crops, though it is widely used in tomato greenhouses with raised-trough systems to improve crop canopy microclimates and fruit yields.

“In the future, I hope to look at year-round production of tomatoes with lighting.”

TEMPERATURE INTEGRATION IMPROVES ENERGY EFFICIENCY

Temperature Integration (TI) is an effective climate control strategy for improving energy use efficiency in greenhouse tomato crops. It basically means applying higher air temperatures when heating costs are lower (warmer outside conditions), and utilizing cooler air temperatures when heating costs are higher (colder outside conditions), all while maintaining the same 24-hour average temperature. Grow pipe usage is important in preventing condensation problems while applying TI.

Since tomato fruit has a lower surface area per unit of volume in comparison to leaves, using TI with a pre-night or pre-morning temperature drop leads to higher fruit temperatures compared to the leaves, and this has the effect of changing the plant growth balance in favour of more fruit production early in the season, when prices are higher.

|

|

| Research technician Celeste Little measures stem lengths.

|

“You don’t use any more energy at all,” Hao explains. “The whole idea behind Temperature Integration with a pre-night or pre-morning temperature drop is to improve energy efficiency and early yields.”

He previously studied low pre-night TI. Temperatures were lowered between 6 p.m. and 9 p.m., and fruit temperatures were found to be 1-2˚ C warmer than leaf temperatures during this time. Fruit yield was improved during the early season.

Hao and his team have more recently followed up on this work with a low pre-morning TI study. Again, the temperature was lowered for three hours, in this case from 3 a.m. to 6 a.m.

“You have to use this together with a grow pipe,” he says. “This will help to prevent humidity and condensation problems.”

The energy savings were greater with the pre-morning application, because the energy requirements were highest in the pre-morning hours.

The TI shifts production earlier, when prices are the highest. “The total crop yields may not change, but there will be higher yields when prices are the best.” ■

Print this page