News

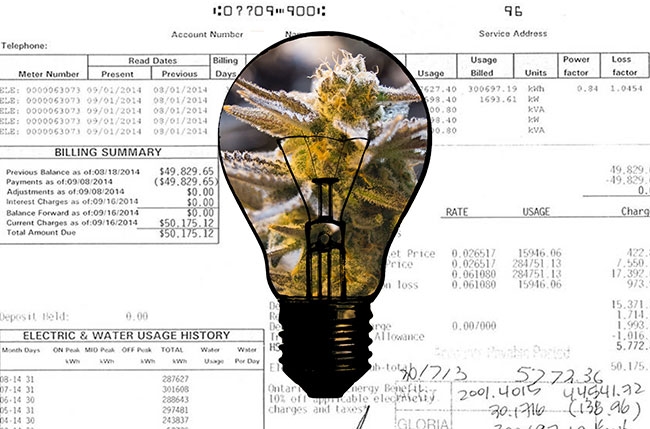

Cannabis and Energy Usage

Essential to track and examine data on your utility bills to benchmark against yourself.

December 11, 2017 By 360 Energy

Those who pay attention to energy from the start will find themselves much better positioned for success.

Those who pay attention to energy from the start will find themselves much better positioned for success. Dec. 11, 2017 – Like many sectors, the cannabis industry underestimates the importance of optimizing energy costs, and the value of managing energy usage and energy supply in tandem. Cannabis growers are currently focused on adapting to evolving regulations and managing a business plan for an undeveloped market.

Both of these steps are fundamental to success. Furthermore, high projected profit margins at the beginning mean that focusing on these two areas alone still generates success. Experience shows that this is only true in the short term.

In both the broader greenhouse market and in mature cannabis marketplaces, when competition increases and profit margins narrow, the most successful operations are those that understand and proactively manage their energy usage and energy costs. While it is possible to improve energy practices as time goes on, it is much more cost-effective to be efficient from the start. This means applying best practice operations and procedures, supplemented by the most efficient technology available for new construction and retrofits.

If you are a cannabis grower building a new greenhouse or indoor growing facility, this means evaluating all building materials and equipment for their expected energy impact and ensuring that they are right-sized for your needs. Is your lighting appropriately scoped to minimize electrical cost, increase production and take advantage of electrical market options? Has your utility confirmed there is adequate infrastructure in your region to accommodate your expected peak demands. Your facility design specifications can be used in conjunction with your lighting and heating schedules to forecast energy usage. With this you can more accurately forecast energy costs when applied in conjunction with market projections and a detailed understanding of your jurisdiction’s electricity and natural gas markets and rate structures.

Taking over an existing greenhouse, the process is generally the same, with a few additions:

- Undertake an energy audit of the facility – understand and model all the variables that impact energy use.

- Examine existing energy infrastructure to ensure sufficient capacity for your operations.

- Include past facility performance as part of your forecast, with an analysis adapted for your new requirements and type of operation.

Once operational, it is essential to track and examine the data on your utility bills to benchmark against yourself, setting a pattern of continuous improvement. Most growers will have this data but it often remains in a file folder. Data accessibility is one of the biggest challenges faced by growers across North America. This prevents it from being analyzed and put to use in finding and sustaining energy savings. Tracking can be as simple as a spreadsheet in the hands of a competent user. There are also purpose-built software services to streamline the data collection while providing simpler and more informative analysis options. An experienced consultant can train your team to apply that analysis effectively.

In our experience, cannabis growers are experts at growing cannabis but need to build depth of knowledge and expertise to address energy in large-scale greenhouse operations. This means they are less experienced with energy efficiency, energy markets, and utility processes.

Entering the industry while ignoring the impact of energy on your business could be successful in the short term. As the market matures, those who paid attention to energy from the start will find themselves much better positioned for success.

This article was supplied by 360 Energy, one of North America’s leading energy services firms.

Print this page