Features

Inside the ‘Fresh Greens’ Container Farm

Steel shipping containers, converted to produce fresh garden greens, root crops, or even flowers, are popping up on the landscape. Here’s a look inside one in southern Alberta.

August 7, 2023 By John Dietz

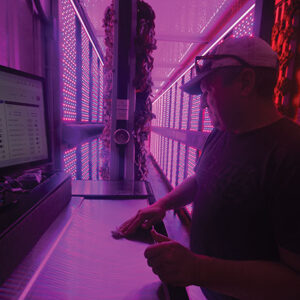

Chad Randal checks on seedlings at Good Life Farms, an operation that grows out of two converted steel shipping containers near Cochrane, Alta.

all photos courtesy John Dietz

Chad Randal checks on seedlings at Good Life Farms, an operation that grows out of two converted steel shipping containers near Cochrane, Alta.

all photos courtesy John Dietz For the good health of local folks, and hopefully for their own profit, Chad and Nicole Randal have reinvented themselves as suppliers of fresh greens for neighbouring Cochrane, Alta. Cochrane is in the foothills of the Rocky Mountains, about 20 minutes northwest of Calgary.

They turned on the power and started growing fresh green vegetables in the unlikely month of December 2022, inside two new 40-foot buildings on one of their rural properties.

The buildings are an ultra-modern set of converted steel shipping containers once used for ocean-going freight. Inside, computer-controlled lighting, temperatures, ventilation, humidity and nutrient-flows provide lab-like growing conditions tailored for pest-free, disease-free perfect production of whatever they choose to grow. They can choose from several hundred varieties of leafy crops, root vegetables, herbs and even flowers.

Solar panels on each roof generate a portion of the energy needed inside. A trickle of water is supplied from the glacier-fed Bow River. The insulated walls, floors and roof give each building independence from the local weather.

And, they didn’t need to build it. Their ‘farm’ was shipped by truck from the “Freight Farms” factory where they are manufactured near Boston, Mass. A local contractor brought in the power supply and ‘plugged’ them into Alberta’s electrical grid. The Randals invested approximately $100,000 for site preparation and $200,000 for each ready-to-grow container.

Chad calls it Good Life Farms. Primarily, it’s his project. Nicole and her younger daughter, Megan, operate an equestrian centre a few miles away. The older daughter, Emily, is a Red-Seal chef in training with a large hotel chain and is involved with helping dad develop the new enterprise.

Mid-life Change

Container-farming is a midlife career change for Chad Randal. He’s an entrepreneur, enthusiastic, socially minded, and mission oriented.

He left a two-generation farm in the 1980s, became a certified engineering technologist and worked in the environmental sciences world on and off for about 30 years.

“We built one of the largest water recycling mobile fleets in North America for the oil and gas industry,” he said.

After they sold their business, Chad and Nicole moved to Dubai, capital of the United Arab Emirates. From September 2021 to June 2022, they were busy at the World Expo hosted by Dubai.

“I started a business there, supporting countries with water treatment issues,” he explains. “I became an Emirate citizen because I had an operating business in Dubai, and we stayed almost a year.”

During the extended visit on the Arabian peninsula, Chad attended the nearby Abu Dhabi Sustainability Week Conference in January 2022. He encountered a Singapore company manufacturing containerized greenhouses.

“We toured their booth and asked to see one. Then we found companies doing these in Canada and the United States. We evaluated different companies and decided to buy from Freight Farms. We ordered two in February 2022 and received them in May,” he said.

Freight Farms has sold more than 600 units in 41 countries. As of Summer 2023, it has 38 units in Canada. They are being used by small business, education, and non-profit organizations.

It would take two to four acres of land to grow the same amount of product as one high-intensity, year-round sealed-environment, hydroponic, vertical-walled, Greenery S container, according to Freight Farms. Power usage amounts to 190 to 230 kWh/day and typical water usage is only five gallons/day. Workspace is adjustable, can be customized, and has an area for seedlings.

“The high-efficiency LED lighting pretty much keeps them warm in winter. An HVAC system circulates air, reuses available carbon dioxide, and has a heat exchanger to reduce energy consumption,” he says. Solar power, set up by his brother-in-law in Sundre Alta. (Kelmar Electric), offsets about half of one unit’s energy consumption and reduces risks from outages or brownouts.

Freight Farms provides comprehensive on-site training in Massachusetts as well as ongoing technical support, production supplies and other services. A proprietary software, Farmhand, operates the growing platform, keeping growers updated with Wi-Fi.

Leafy greens, lettuce and herbs are the primary crops. Routinely, they are harvested in three to five weeks. Root crops (with edible leaves) include beets, carrots, radishes, bunching onions, turnips and kohlrabi. Experimental crops include flowers (calendula, celosia, nasturtium, nigella, viola, yarrow and zinnia). Then there are microgreens – very young seedlings.

Randal grew arugula and Graziano leaf lettuce, KC butterhead lettuce, turnips, radishes, carrots and even tomatoes in the first months.

Six months into his new career, one container was full and the other was half-full.

Randal said, “We harvest, and we plant weekly. Every week we can produce 1,000 to 2,000 heads of lettuce. We do a little bit of herbs and roots, and we have an experimental chef’s wall that we really enjoy. We share as a family and with the community. Last weekend, we sold out, but I always grow more than I sell, so we donate that to community groups. We believe in helping families, so we’re doing that.”

Staffing and Marketing

Staffing Good Life Farms has been fairly simple. There’s a local supply of part-time, semi-retired labour. Packaging and market development have been challenging.

Nicole helps on occasion. His daughter the chef helps with product selection. Local pensioners help with marketing, sales, deliveries, planting, harvesting, technical aspects, as needed.

In Cochrane and nearby Calgary, major retailers have established price points for fresh produce. Good Life Farms has to compete.

“We’re coming into something established, sharing what we’re capable of doing, and people decide to buy or not. We’ve been able to meet the price points and, I think, people see it as a premium product,” Randall says.

“We need to be profitable enough to continue the operation or grow it, but I’m not motivated the same as large corporate shareholders and investors. My social license says, I would rather see people fairly get as much food as they want, have the best quality they could, and have it at a reasonable price. That’s what this is really about, our community, our next generation.”

Packaging and marketing take time and cost money. He invested in a packaging facility with equipment for it like printers and label makers. But no matter how fresh and shelf-perfect, his product has to fit into food regulations as well as retail displays.

“It’s one thing to be a farmer and grow, which is what I want to do. The packaging and marketing side can take a huge amount of time and cost. You have to take a look at what you want to do, working with a chef, selling to the local farmers market, or selling to a wholesaler. Where do you want to be?”

Frankly, says the entrepreneur, his new career is still a work in progress. He may change direction, but his vision is fixed.

Big picture

“I’m a little agnostic on this yet,” Randal says. “I’m trying these farms. I want to know everything about them before I suggest anybody else takes the risk. There are other farms. The Canadian company, Growcer, looks really good, too, and I may look into mushroom farming as well. We’re even looking at the fodder technology for our equestrian facility.”

In the Arabian peninsula, the former water treatment specialist and conservationist saw a bigger picture of the future. He’s brought it home as an enterprise to develop. Randal believes that in the big picture, the future of farming may be in indoor high-intensity vertical farming systems like his high-tech shipping containers.

He says, “Land is so expensive. Water is scarce. Container technology can provide a reliable, perfect environment for year-round growth. And a standby generator could replace or supplement solar power if needed.”

He adds, “If I can inspire anybody else to do this, I’ll be so happy. There’s such a need, there’s more opportunity (for local food production) than I can ever imagine or take on.”

Print this page