Features

Focus on: Lighting

Finding the right light recipe

Review of recent greenhouse vegetable lighting research at Agriculture and Agri-Food Canada’s Harrow Research and Development Centre

October 16, 2023 By Dr. Fadi Al-Daoud (Ontario Ministry of Agriculture, Food and Rural Affairs) and Dr. Xiuming Hao (Agriculture and Agri-Food Canada)

Pepper plants with poor architecture and fruit stacking

PHOTOS: Agriculture and Agri-Food Canada

Pepper plants with poor architecture and fruit stacking

PHOTOS: Agriculture and Agri-Food Canada Summary and conclusions

The market demand for locally grown fruits and vegetables year-round has driven adoption of lighting technologies for winter food production in greenhouses and vertical farms in Ontario. Here, we review some of the lighting research conducted at Agriculture and Agri-Food Canada’s Harrow Research and Development Centre (Harrow, Ont.) over the past several years. Generalized recommendations for light intensity, photoperiod and daily light integral (DLI) are summarized in Table 2 for practical commercial greenhouse production using overhead lighting (HPS, LED, or a hybrid system of HPS and LED). This article also highlights a few studies conducted in Harrow to test different combinations of overhead, inter-lighting, and dynamic long photoperiod, low intensity lighting recipes for winter production of cucumbers, tomatoes, peppers, and microgreens. You will find detailed information about the light recipes used in the studies and their results. Overall, the inclusion of LED inter-lighting with overhead HPS lighting boosted early production numbers in cucumbers, and small doses of far-red light with HPS lighting or LEDs benefited winter tomato and pepper production. Dynamic light recipes for long photoperiods (up to 24 hours) for greenhouse production of tomatoes, cucumbers, and peppers in the winter and microgreens in vertical farms were also identified. The next step is to incorporate the information gained from dynamic long photoperiod lighting research into dynamic lighting control programs to significantly reduce light fixture costs and energy costs.

Introduction

The impressive growth of Ontario’s vegetable greenhouse sector over the past decade or so would not have been possible without advancements in lighting research and technologies. More efficient light fixtures such as light-emitting diodes (LED) and new double-ended, high-pressure sodium (HPS) lights have allowed producers to be able to extend their vegetable growing seasons into the dark winter months in an economically sustainable way. The ability of LED lights to be adjusted to different light intensities and light spectral outputs was a game-changer.This allowed producers and researchers to experiment with different light recipes to optimize the light environment for their crops.

Pepper plants with short internodes.

PHOTOS: Agriculture and Agri-Food Canada

Before the commercialization of LED lights, HPS lights were used as only overhead lights for vegetable greenhouse production because the high operating temperature of HPS light bulbs did not allow them to be used close to the canopy. HPS lights also only provided one spectral output that was not adjustable. LED lights changed all that. The lower operating temperature of LED lights allowed them to be used not only as overhead lights, but also as inter-lighting within the canopy of vine crops like tomato, cucumber, and peppers. Also, by adjusting the spectral output of LEDs it became much easier to manipulate canopy architecture, and this allowed crops that were not able to grow well under HPS lights to grow under LED lights.

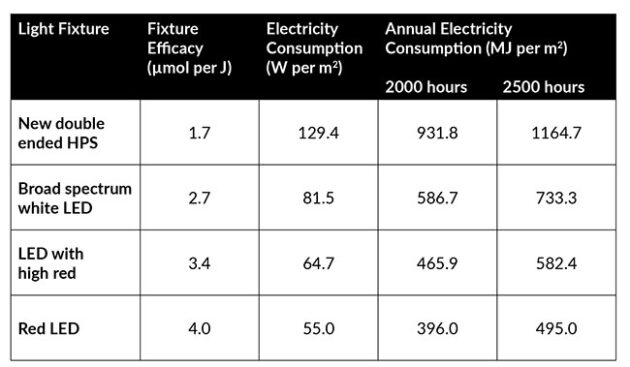

The difference in efficacy of light fixtures is another important consideration. LED lights are typically more efficacious than HPS lights (Table 1). The efficacy of fixtures when producing photosynthetically active radiation (PAR, 400-700 nm) is measured in the number of photons (µmols) per joule (J) of electricity it consumes. The higher the number of µmol per J for a fixture, the more light it produces per J, the more efficacious it is. The efficacy of HPS lights ranges from 0.9-1.8 µmol per J depending on the type, whereas the efficacy of LED lights typically ranges from 2.0-4.0 µmol per J.

TABLE 1

Typical energy input of light fixtures to achieve 220 µmol per m2 per second of PAR.

But growing greenhouse vegetables in the winter using supplemental lighting is not as easy as flicking a switch. Growers need to adjust their cultivar selection, crop schedule, plant density, training systems, climate control, and irrigation schedules. The most obvious change is cropping schedule. Non-lit greenhouse vegetable production of high wire tomatoes, peppers, and cucumbers typically starts with planting around December and January and harvesting ends around October and November for cleanout. Whereas growing these crops in the winter or for year-round production using supplemental lighting typically starts with planting around September and October and harvesting ends around July or August. In addition to changing the cropping schedule, the climate controls and irrigation schedules must be adjusted for winter production under lights to reflect the three periods with different light conditions when there is:

- Natural daylight only or daylight plus artificial light

- Artificial light only

- Dark nighttime

Irrigation should start when the supplemental lighting is turned on, which is typically a few hours before sunrise. Supplemental lights should be turned off around one hour before sunset to allow pollinating bees to return to their hives at this time, otherwise they might get disoriented by the artificial light. Cultivar selection also changes when growing with supplemental lighting. Many greenhouse vegetable cultivars that are suitable for non-lit production may not be suitable for winter production under supplemental lighting. The type of supplemental lighting also affects cultivar selection. For example, HPS lights may cause faster senescence in generative cultivars, while LED lights may delay fruit production in vigorous cultivars.

When designing a lighting strategy for tall greenhouse vegetables, there are four main components that growers should think about:

- What intensity of light should be used? This is usually called the photosynthetic photon flux density (PPFD) and it measures the amount of PAR light that plants are receiving in micromoles (µmol) per meter squared (m2) per second.

- What photoperiod should I use? The photoperiod is the length of time that there is light whether it is sunlight or artificial light, and it is typically measured in hours. When you multiple the light intensity (in moles per m2 per hour) by the photoperiod (in hours) you get the daily light integral (DLI). This is the total accumulated amount of light that plants are receiving in one day measured in moles (mol) per m2 per day.

- Which light spectrum should be used? This is the light quality or light colour that is produced by the light fixtures measured in nanometers (nm). Broad spectrum white light typically covers the PAR spectrum (400-700 nm), blue light is 400-500 nm, green/yellow/amber light is 500-600 nm, red light is 600-700 nm, and far-red light is 700-800 nm.

- What vertical distribution of light should be used? Lights can be used as top lighting above the canopy, inter-lighting within the canopy, or a combination of both. As mentioned earlier, HPS and LED lights can be used in different ways.

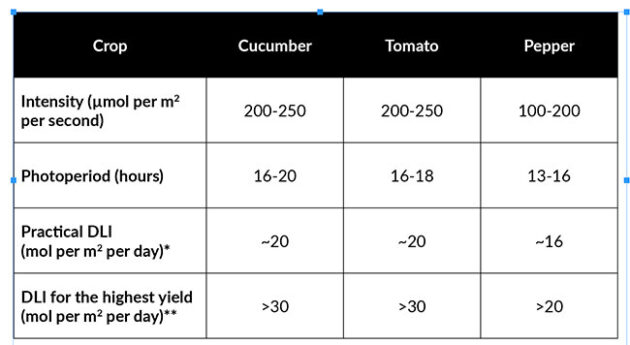

TABLE 2

TABLE 2

Implementation of supplemental lighting in winter greenhouse vegetable production.

* This is the total DLI (sunlight + supplemental light) normally used in commercial production to maintain good production. Higher DLIs may further increase yield but not necessarily higher profits because the additional yield gain may not justify the additional input costs. ** This is the total DLI to achieve the highest yield.

The general standard light intensity, photoperiod, and DLI values used today for winter production of high wire tomato, cucumber, and peppers are shown in Table 2. Please note that these values do vary with cultivar, local climate, and light fixture.

Since 2002, much of the lighting research that helped advance Ontario’s vegetable greenhouse industry was conducted by scientists at Agriculture and Agri-Food Canada’s Harrow Research and Development Centre in collaboration with other research institutions. This article aims to highlight and summarize a few of the vegetable greenhouse lighting research conducted in Harrow over the past decade or so (2012-2022). Each of the sections below includes information that is specific to a different greenhouse crop (cucumbers, tomatoes, and peppers) and information about the light recipes used by the researchers and the results of the trials. The last section includes information about dynamic lighting research that was conducted on multiple crops (tomatoes, cucumbers, peppers, and microgreens). The dynamic lighting research will allow producers to truly take advantage of the flexibility in output offered by LED technology to reduce energy costs.

Cucumbers, overhead HPS, and inter-lighting LED lights

Lighting Recipes: Some of the earliest vegetable lighting trials in Harrow were published by Hao et al. in 2012 and 2015. These trials were conducted on mini cucumbers. The first set of trials investigated combined HPS overhead lighting with LED inter-lighting systems. The crop was grown under 145 µmol per m2 per second of HPS overhead lighting in combination with 14.5 µmol per m2 per second of LED inter-lighting (10 per cent of top light). Red (660 nm), blue (460 nm) and white (broad spectrum 400-700 nm) inter-lighting fixtures were tested to determine the best colour. The photoperiod varied between 12 and 20 hours depending on natural light conditions. Supplemental lighting treatments increased as the crop aged, from 12 hours per day the week after the planting to 20 hours per day when a full canopy had developed. The inter-lighting was placed 60 cm above the raised trough close to the harvesting fruit.

The second set of trials focused on optimizing the combination of HPS overhead lighting and red/blue inter-lighting by testing different overhead intensities (120 and 165 µmol per m2 per second) and different intensities of inter-lighting (one or two rows of red/blue LED producing 36.7 µmol per m2 per second of light for each fixture). These trials also tested different planting densities (2.8 and 3.6 plants per m2) to determine if more or less plants affected the response to inter-lighting. The HPS top lights were placed three metres from the ground and the LED inter-lighting was placed at mid-height of the crop canopy. When there were two inter-lighting modules included, one was placed about 60 cm above the bottom edge of the crop canopy and the other module was placed 40 cm above the bottom module. Together the two modules provided 73.4 µmol per m2 per second of red/blue light. The photoperiod varied between nine and 20 hours and the supplemental lighting treatments increased with crop age in a similar way to the first set of experiments. The supplemental lighting always ended just before sunset, the longer photoperiods were achieved by starting the lighting earlier in the night such as at 11:00 PM for the 18-hour photoperiod.

Results: In the first set of experiments, plants with blue LED inter-lighting were taller than plants with no inter-lighting under HPS overhead lights. Plants exposed to red and white LED inter-lighting treatments had more leaves than plant with no inter-lighting. Red, blue, and white LED inter-lighting all improved fruit visual quality and increased yield more than 10 per cent in early production. However, yield improvements associated with LED inter-lighting were not as significant during late production periods.

In the second set of experiments, without HPS top lighting, single LED inter-lighting increased marketable fruit weight by 32 per cent over the control without any supplemental lighting. The combination of HPS overhead lights and LED inter-lighting once again increased yield and fruit quality over HPS overhead lights alone. In combination with the less intense HPS top lighting the double rows of LED inter-lighting increased marketable fruit weight by 42 per cent over the top lighting alone. The single LED inter-lighting and the more intense HPS top lighting increased marketable fruit weight by 10 per cent over the top lighting alone, and the mini cucumbers were greener. Best results with low intensity top lighting and inter-lighting were realized when lower plant density was used. In contrast, higher plant density showed the best results with higher intensity top lighting and inter-lighting.

Tomatoes, HPS, and far-red light

Lighting Recipes: One of the first studies on far-red light in Harrow was published by Hao et al. in 2016. It investigated the effect of adding far-red light (725-750 nm) on tomato plants grown under HPS lights. Tomato plants grown under HPS lights with 165 µmol per m2 per second were provided with four far-red intensity treatments (0, 8, 16, and 24 µmol per m2 per second). The photoperiod started at 1:00 AM and lasted until 5:00 PM in December, 5:20 PM in January, 6:02 PM in February, and 7:10 PM in March. All lights were shut off when outside solar radiation was more than 300 W per m2.

Results: Supplemental far-red light provided benefits in the early growth period during the winter when natural far-red light was low. The internode length and the chlorophyll content of young leaves increased with higher intensity of supplemental far-red light. Yield and size of the tomato plants also increased significantly, by as much as six per cent for marketable fruit, with far-red light treatments in the first month of the trial (January to February). Far-red light also changed the fruit quality by increasing total carotenoid content of the fruit. The benefits of far-red light, however, did not persist into the later growth periods in March when there was more natural far-red light.

Overall, the low dose of far-red light (8 µmol per m2 per second) achieved similar fruit yield as the higher doses and used less electricity and had lower capital and installation costs. This intensity is lower than the far-red light intensity mentioned in the pepper section below because these HPS lights had about 10 per cent far-red light, or about 17 µmol per m2 per second, in addition to the far-red LED treatments.

Peppers, HPS, LED, and far-red light

Lighting Recipes: Hao et al. (2019) presented data from experiments on the effect of far-red light on bell pepper plants conducted between November, 2017-June, 2018. Plants were grown under 200 µmol per m2 per second of 1) HPS, 2) HPS and LED hybrid, 3) white LED, and 4) red/blue LED lights. An 18-hour photoperiod was used, and the lights were off when outside solar radiation was more than 300 W per m2. Each of these overhead light treatments also included 0, 26, or 52 µmol per m2 per second of far-red light. Without supplemental far-red light, the HPS lights already produced some far-red light whereas the LED lights did not.

Results: Pepper plants grown under white LED lights were the tallest (12-15 per cent more) and had the least amount of leaf chlorosis (73-90 per cent less). Those grown under red/blue LED lights were the shortest with moderate leaf chlorosis, whereas the plants grown under HPS lights had the most leaf chlorosis and moderate height, as compared to the other treatments. Adding far-red light increased the height of plants grown under all the lights by three-to-seven per cent, except the plants grown under white LED lights which were already tall. Far-red light also increased yield by 4-14 per cent under all lighting treatments, except for red/blue LED lights with the low far-red dose. Unlike tomatoes, these yield increases were observed in the later stages of winter production.

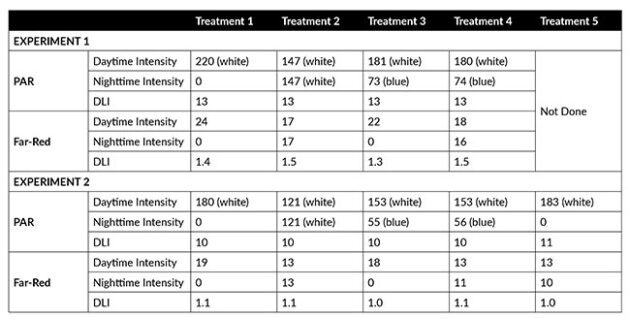

TABLE 3

Daytime and nighttime light colour, intensity, and DLI for 16- and 24-hour lighting treatments on peppers. All light intensity values were measured in µmol per m2 per second, and the DLI numbers were in mol per m2 per day.

Dynamic, long photoperiod, low intensity lighting of tomatoes, mini cucumbers, peppers, and microgreens

Yield increases from supplemental lighting are mostly determined by the added DLI, as summarized by the simplified Dutch saying of “one per cent of light increase = one per cent yield increase.” The required DLI can be met over a shorter period of time with higher intensity lighting or a longer period of time with lower intensity lighting. Using a longer photoperiod with lower intensity lighting can significantly reduce light fixture costs in comparison to a shorter photoperiod and higher light intensity, because less lights would need to be installed. Furthermore, in regions such as Ontario with large fluctuations in electricity prices at different times of the day, longer photoperiods will allow much more flexibility to use cheaper electricity to meet the target DLI thereby significantly reducing electricity costs. However, plants have a biological clock and need “sleep”, just like humans. If the photoperiod is longer than certain thresholds, such as 16-17 hours for tomatoes, it will lead to leaf injury and yield reduction. This is known as photoperiod injury. In order to extend the photoperiod for greenhouse crops without photoperiod injury, we need to first find ways to overcome the crop’s biological clock to allow normal or better plant growth and development.

Therefore, in recent years the research in Harrow has focused on testing various lighting recipes under longer photoperiods (up to 24 hours) and reduced intensities of light to find ways to overcome photoperiod injury. This was done using dynamic lights that were able to produce different light spectrums at different intensities at different times of the day.

Tomato 24-hour dynamic light recipes and results: The first successful 24-hour light trial conducted by scientists in Harrow was published in 2019 (Lanoue et al., 2019). It examined tomato greenhouse production under 24 hours of supplemental lighting using alternating red light (200 µmol per m2 per second from 6:00 AM to 6:00 PM) and blue light (50 µmol per m2 per second from 6:00 PM to 6:00 AM). This was compared to a 12-hour lighting photoperiod with red and blue lights (red at 200 µmol per m2 per second plus blue at 50 µmol per m2 per second from 6:00 AM to 6:00 PM). Lighting was applied from November to May. The supplemental lighting remained on regardless of sunlight radiation levels to ensure that both treatments received the same total DLI.

Plants grown under 24-hour lighting grew in a similar manner to those under 12 hours of light, but they produced 12 per cent more leaf area and 10 per cent more stem fresh weight. Plants under both light recipes also produced similar numbers of fruit, but the fruit produced by plants grown under 24-hours light weighed 15 per cent more than the fruit produced by plants under the 12-hour light recipe. However, these differences were only seen in the early weeks of the experiment. Plants grown under both light recipes were similar later in the growing season.

Mini cucumber 24-hour dynamic lighting recipes and results: Another study published in 2021 by Lanoue et al. investigated production of mini-cucumbers under 24-hour lighting. There were four treatments:

- 16 hours (6:00 AM to 10:00 PM) of red light (149 µmol per m2 per second) plus blue light (25 µmol per m2 per second)

- 24 hours of red light (96 µmol per m2 per second) plus blue light (17 µmol per m2 per second)

- 24 hours of alternating red light (151 µmol per m2 per second for 16 hours, 6:00 AM to 10:00 PM) followed by blue light (40 µmol per m2 per second for eight hours, 10:00 PM to 6:00 AM)

- 24 hours of alternating between red light (210 µmol per m2 per second for 12 hours, 6:00 AM to 6:00 PM) followed by blue light (31 µmol per m2 per second for 12 hours, 6:00 PM to 6:00 AM).

All treatments had the same DLI of 10 mol per m2 per day. Lighting began in November and the lights remained on regardless of solar radiation to ensure all lighting treatments had the same DLI.

All plants grown under 24-hour lighting had higher chlorophyll content in their leaves compared to the 16-hour photoperiod treatment, but no other differences in growth or yield were observed between the treatments. However, the 24-hour lighting regimes had an economic advantage over the shorter period of lighting in achieving the same DLI with less light fixtures and shifting some electricity demand to overnight hours when prices are typically low in Ontario.

Pepper 24-hour dynamic lighting recipes and results: A recent paper published in 2022 by Lanoue et al. investigated the use of far-red light in a 24-hour lighting recipe for bell pepper plants (Lanoue et al., 2022a). Five treatments were included:

- 6 hours of white light (400-700 nm)

- 24 hours of white light

- 24 hours alternating between white light (for 16 hours) followed by blue light (400-500nm, for eight hours)

- 24 hours alternating between white light (for 16 hours) followed by blue light and far-red light (700-800 nm for eight hours)

- 24 hours alternating between white light (for 16 hours) followed by far-red light (for eight hours)

Two experiments were conducted with the above treatments. The first experiment had a PAR DLI of 13 moles per m2 day and far-red DLI of 1.3-1.5 moles per m2 per day, and the second experiment had a PAR DLI of 10-11 mol per m2 per day and a far-red DLI of 1.0-1.1 mol per m2 per day (Table 3).

Fruit yield and fruit size was similar in all treatments, except for plants under 24 hours of white light that had lower fruit number and fruit weight than all other treatments. Both lighting treatments that included nighttime far-red light resulted in improved canopy architecture with 54-63 per cent taller plants and increased internode length, which prevented fruit stacking. This was observed consistently in early and late production periods.

Microgreen 24-hour dynamic lighting recipes and results: In another recent publication in 2022, Lanoue et al. investigated the effect of 24-hour white light on the growth of four types of microgreens: amaranth, collard greens, green basil, and purple basil (Lanoue et al., 2022b). These experiments were conducted in growth chambers, so they apply more to vertical farmers than greenhouse growers. Some seedlings were exposed to a DLI of 14-15 mol per m2 per day under 16 hours of light (251 µmol per m2 per second) or 24 hours of light (167 µmol per m2 per second), while other seedlings were exposed to a higher DLI of 21-22 mol per m2 per day under 16 hours of light (377 µmol per m2 per second) or 24 hours of light (248 µmol per m2 per second).

Increases in yield (fresh weight) were observed for all microgreens including a 93 per cent increase in amaranth, 46 per cent increase in purple basil, 43 per cent increase in green basil, and a 21 per cent yield increase in collard greens when the photoperiod was extended from 16 hours to 24 hours using the same light intensity. Food quality as measured by antioxidant, phenolic, anthocyanin, and chlorophyll content, was generally not affected or increased under 24 hours of lighting. Furthermore, the electricity cost per unit of fresh biomass was reduced by 8-38 per cent in all microgreens when they were grown under 24h lighting because some electricity demands were shifted from more expensive on-peak daytime hours to cheaper off-peak nighttime hours.

Print this page