Features

Business

Research

‘Centre’ of research: North America’s largest complex showcases its latest projects

June 9, 2008 By Dave Harrison

There’s always considerable

interest, both at home and abroad, in work being done at North

America’s largest greenhouse vegetable research centre.

|

| Dr. Tom Papadopoulos is leading research into organic production methods. |

|

| Open house display. |

|

| The high yield and good quality of mini-cucumber with the high-wire system. |

|

| Marketing coordinator Laura Brinkman, at left, and market analyst Diane Prvulovic, with the OGVG’s recipe book. |

There’s always considerable interest, both at home and abroad, in work being done at North America’s largest greenhouse vegetable research centre. And attendance at this spring’s open house confirmed it, as one of the largest turnouts in memory – including more flower growers – toured the 7,000 square metres of research projects and trials. Some 200 growers attended.

About 85 per cent of Ontario’s greenhouse vegetable production is located within 25 kilometres of the Greenhouse and Processing Crops Research Centre in Harrow. The Centre is just minutes from Windsor.

This year’s open house illustrated the broad range of projects being undertaken, including:

• High-wire mini-cucumber production with supplemental lighting.

• Organic pepper production.

• Chemical control of Phytophthora blight with peppers and cucumbers.

• New potential applications for the predatory mite, Amblyseius swirskii.

• Assessing a new minor use candidate for the control of Pythium aphanidermatum in tomatoes.

Thanks to funding support from Flowers Canada Ontario, a number of ornamental projects are also underway (hence the growing number of flower growers in attendance). Following are some open house highlights.

A BUSY YEAR UNDERWAY FOR OGVG SAMPLING PROGRAM

A longtime and major supporter of research at the Centre is the Ontario Greenhouse Vegetable Growers association. The investment pays major dividends for members, the OGVG noted in a recent media release. “New technologies, products and techniques are constantly in development,” said OGVG research coordinator Cheryl Trueman. “Supporting research helps our producers learn which tools to adopt for more efficient and environmentally friendly production.”

The OGVG helped support 11 projects in 2007. These projects were also supported by the Canada-Ontario Research Development (CORD) program, an initiative of the federal-provincial-territorial Agricultural Policy Framework. The Agricultural Adaptation Council administers CORD on behalf of the province.

OGVG will be involved with 11 additional projects this year and in 2009.

It had a booth at the open house, highlighting a number of its programs. Included was the OGVG’s recipe book, a big part of its marketing efforts. This year, for example, the OGVG will sponsor 100 instore demonstrations in Michigan for the first time, and a further 350 demos in Ontario. Consumers will be given a recipe book after taking the time to fill out a short survey.

SOME ENCOURAGING WORK WITH ORGANIC RESEARCH

Dr. Tom Papadopoulos, a senior research scientist at GPCRC, is heading a national research project looking at organic vegetable production strategies. Working with him are Dr. Xiuming Hao and Shalin Khosla at Harrow, Dr. David Ehret and Dr. Wei Lin at the Agassiz facilities of the Pacific Agri-food Research Centre in British Columbia, and Dr. Martine Dorais (AAFC) at Laval University.

This is the final year of a three-year project. The team looked at tomatoes and cucumbers during the previous two years. The project wraps up this year with peppers. Two interim reports have been released already and a final report will be issued on completion of the project.

Tomatoes performed quite well. The first crop achieved about 75 per

cent of conventional rockwool yields. After some fine-tuning of

different organic media and fertilizers, the second crop achieved 92

per cent of conventional rockwool yields.

“With more time, we could push the yields even higher, but the project was limited to three years.”

Cucumbers were a different story. “They didn’t perform as well,” said Dr. Papadopoulos.

Results so far with

peppers are encouraging, though harvesting had yet to commence at the

time of the mid-April open house. “The plants are setting fruit quite

well, so far.”

Some treatments are doing better than others. Four liquid feeds and

four media have been utilized to see which work best and in which

combination. The goal is to develop completely integrated production

systems.

|

| A close-up view of the organic media. |

“Many growers look at organic growing as a new opportunity for the

industry to expand the market, because the demand for organic produce

is strong and growing” said Dr. Papadopoulos. “We’re heading into more

and more challenges with marketing tomatoes, cucumbers and peppers

because of the strong Canadian dollar and high energy costs.”

It’s a niche opportunity,

much like the different kinds greenhouse vegetables now enjoying

success, including cocktail tomatoes and mini-cucumbers. “Organic

produce is just another type of the same crop.”

It wouldn’t take a lot

for growers to switch over to organic production using the systems

being developed at GPCRC. It’s the same basic production model they’re

already using, including the use of raised gutters. “The only thing

they would do differently is prepare the media. It’s really not that

much more work and the machinery isn’t that expensive.”

|

| Dr. Rosemarije Buitenhuis has been involved with a pair of A. swirskii studies. |

|

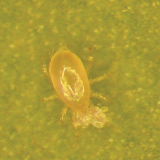

| A. swirskii eating cucumeris larva. Photo Courtesy AAFC |

|

| A. swirskii eating thrips. |

It is a little time consuming, as the material being composted must be regularly turned. The Harrow compost includes soy meal. It has a lot of protein, which breaks down into ammonia and eventually into nitrate.

Mildew has been a problem during the trials, but overall, there haven’t been any more disease issues than growers would be used to with conventional production systems. The same biologicals are used for pest control.

Grower interest in the organic research was quite steady during the open house, though that shouldn’t be surprising. The organic market “is strong and growing,” said Dr. Papadopoulos.

Project sponsors include the Ontario Greenhouse Vegetable Growers, the BC Greenhouse Growers Association, AgrowChem Inc., CH2O, Agrogreen Canada Inc., VGROVE Inc., and the Matching Investment Initiative program of Agriculture and Agri-Food Canada.

THE VERSATILITY OF AMBLYSEIUS SWIRSKII

Amblyseius swirskii has proven quite an effective generalist predator. Two studies are helping scientists get an even better understanding of its capabilities and limitations.

Dr. Rosemarije Buitenhuis is part of the team headed by Dr. Les Shipp taking a closer look at A. swirskii. Also involved is visiting scientist Dr. Hong-Hyun Park.

A. swirskii is already a seasoned veteran in the greenhouse, proving quite effective in controlling whitefly and thrips. However, it has never been used as a primary control agent for mites. There is anecdotal evidence from Europe that swirskii can provide effective control for broad mites on sweet peppers.

Given that there’s presently no pesticide registered to control russet mites in tomatoes, the researchers are studying to see if swirskii has potential. “A control option is really needed,” said Dr. Buitenhuis.

While the work is quite preliminary, research so far has shown that swirskii can eat 50 to 80 russet mites a day, and further that it was also laying eggs. “If they reproduce, it means it (russet mite) is a good food source.”

The research was done within laboratory conditions utilizing a single leaf. “This is all quite preliminary, but it is showing some promise.”

Dr. Shipp says the next step would be dispersal trials of swirskii on tomato plants. “Can it move easily up and down the plants.”

He emphasized the work with swirskii and russet mite is at a very preliminary stage. “If they can’t move up and down the plant, the project stops there because it wouldn’t be feasible.”

If it works, it will be good news for growers. Russet mites are sporadic problems for growers, but when they have them, “it’s a very big problem.”

The team may also look at using swirskii on broad mites, which are problems for both ornamentals and vegetables. This work could also be combined with spider mites, as well.

The second swirskii project looked at how it interacted with another popular predator, Neoseiulus cucumeris, in the presence of thrips. Since growers use more than one predator, would the two predators prey on each other?

“Swirskii is a very generalist predator,” said Dr. Buitenhuis, so it could be a problem.

They did several studies to see how swirskii and cucumeris interacted. “We wanted to see if they eat each other and we found that that they do.” Swirskii will eat the immature stages of cucumeris, such as larvae and nymphs, while cucumeris will eat the larvae and nymphs of swirskii. Both have difficulty eating the eggs of each other.

In a related study, the researchers found that thrips and the other predator are good food sources for each predator. Taking that one step further, they studied food source preferences when all three – swirskii, cucumeris and thrips – were present.

“The main result was that swirskii actually preferred cucumeris larvae over thrips when given a choice,” said Dr. Buitenhuis. Cucumeris, on the other hand, didn’t show a preference, as it would eat both swirskii and thrips.

“We found that swirskii could potentially be an intra-guild predator of cucumeris.”

She emphasized it is only a “potential intra-guild predator.” The study was only conducted on leaf disks where the predators had no choice but to encounter each other. “The results might be quite different, or at least much less severe, if the study involved a whole plant or a whole crop. That’s why we say only that there is potential for intra-guild predation.”

Besides this study, Flowers Canada (Ontario) is also helping fund a swirskii dispersal study with ornamental plants, such as potted chrysanthemum and gerbera. Does swirskii move down to the bench to disperse, or do they prefer to remain on the foliage and move from leaf to leaf, and on to neighbouring plants if the leaves are interlocking?

Agriculture and Agri-Food Canada provided funding for the russet mite research, while Flowers Canada (Ontario) is supporting the A. swirskii studies with ornamentals.

|

| Dr. Xiuming Hao is heading research into improving year-round production of mini-cucumbers. |

SUPPLEMENTAL LIGHTING WITH POPULAR NICHE CROP

Mini-cucumbers are proving quite popular with consumers. They’re ideal snack items and lunch bag treats, and they work well in salads. Dr. Xiuming Hao is optimizing a year-round production system using supplemental lighting.

“The goal is to have a year-round stable supply of high quality produce,” he said. Prices in the winter should be much higher, though growers may have the additional lighting costs.

There is enough light during the growing period of April through September. The challenge is in maintaining yields and quality throughout the winter. “There’s not enough natural light during the winter months.”

Mini-cucumbers are more labour-intensive than the regular-sized cucumbers, he said, because workers are picking more often. They also require more light during winter production compared to the regular-sized cucumbers.

The research is encouraging. Summer yields range from 2.2 to 2.5 kilograms per square metre per week. In the winter, production drops to about 1.5 kilograms per square metre per week, even with supplemental lighting. “Without lighting, mini-cucumber production drops to a very low level.”

Norway and Finland use supplemental light with cucumbers, and with great success.

Dr. Hao finished a major project last year looking at supplemental lighting on regular-sized cucumber crops. There are now a number of growers in British Columbia, Alberta and Ontario using supplemental lighting with cucumbers.

Dr. Hao’s research suggested potential yields of between 280 and 300 cucumbers per square metre for traditional cucumber crops on a high-wire system and with supplemental lighting. Mini-cucumbers may benefit even more from the same process. Stem growth with minis is much slower than with the regular-sized cucumbers, and that means growers won’t have to deleaf or lower the crop as often.

One of the major benefits of the high-wire system is with fruit harvest. Cucumbers will all be at about the same height and will therefore be much easier to harvest. With the umbrella production system, on the other hand, workers often have to search for the fruit.

The mini-cucumber project is funded by the Research Branch (Peer-Review Process) and the MII (Matching Investment Initiative) Program of Agriculture and Agri-Food Canada, and the Ontario Greenhouse Vegetable Growers (OGVG).

|

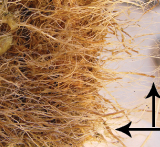

| Light brown (arrows) discoloration of tomato root segments caused by P. capsici in a rockwool block. |

PREVENTIVE APPROACH TO PHYTOPHTHORA THREAT

Dr. Ray Cerkauskas has been studying a disease that could impact both greenhouse and field vegetable growers. Phytophthora blight has been a major problem in field vegetable crops in Michigan, Ohio, Illinois, North Carolina and other states. Crops most affected include pumpkins, cucurbits, peppers and tomatoes.

Isolated cases occurred of phytophthora blight in Ontario pepper fields since 1994, as first reported by GPCRC scientist Dr. Terry Anderson. However, it has not yet become established in the province. “It disappeared for a number of years, but returned a few years ago. We’ve seen it in the field occasionally. It is starting to show up in a few cases in greenhouses.”

This is a fungal disease that is favoured by warm and wet conditions, said Dr. Cerkauskas. Greenhouse media grow blocks are warm and moist, the ideal conditions for the fungus Phytophthora capsici. Because it affects all three major greenhouse crops – tomatoes, peppers and cucumbers – “it has potential to become a problem.”

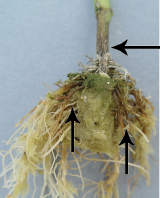

The lower stem of this cucumber plant is yellowish-green and is also shrivelled compared to the upper, healthy part. The shrivelled stem area (arrow) is also beginning to dry. The lower stem of this cucumber plant is yellowish-green and is also shrivelled compared to the upper, healthy part. The shrivelled stem area (arrow) is also beginning to dry. |

This pepper plant is in the early stage of the disease caused by This pepper plant is in the early stage of the disease caused by P. capsici. The canker on the lower stem and crown area (arrow) is evidence of the disease and characteristic of P. capsici. The few dark-brown coloured roots (arrows) on either side of the stem are the first signs of root rotting and eventually all the roots might be infected. |

William Lotosky, a second-year biochemistry major at the University of Waterloo, looks over part of a phytophthora trial being led by Dr. Ray Cerkauskas. The diseased plants are in the front; at back are plants treated with a control. William Lotosky, a second-year biochemistry major at the University of Waterloo, looks over part of a phytophthora trial being led by Dr. Ray Cerkauskas. The diseased plants are in the front; at back are plants treated with a control. |

OMAFRA greenhouse vegetables IPM specialist Gillian Ferguson works closely with Dr. Cerkauskas on researching new sector problems. OMAFRA greenhouse vegetables IPM specialist Gillian Ferguson works closely with Dr. Cerkauskas on researching new sector problems. |

Field vegetable crop producers in the U.S. have a number of chemical controls at their disposal, and Dr. Cerkauskas and his team are examining them to gauge their effectiveness with greenhouse crops. “We’re taking our observations from the field and applying them in the greenhouse.”

The first aspect for disease control involves recognition and identification of the disease based on symptom development. The researchers are determining if the symptoms in the greenhouse are the same as those already observed in the field. “We want to be able to identify it based on greenhouse symptoms.”

It’s important to take a proactive role before the disease becomes a problem, to ensure effective controls are registered in time. “We need to have a chemical control as soon as possible,” said Dr. Cerkauskas. “It’s important growers have something as a preventive measure.

In addition to studying chemical controls, another component of the research is looking at disinfectants to determine optimal application rates. “Sanitation will be very important to prevent this disease.”

Dr. Cerkauskas credits OMAFRA greenhouse IPM specialist Gillian Ferguson with keeping the Centre on top of any disease problems. “If a problem comes up, and she’s not sure if it is something new, she can bring it into our lab right away. We can talk about what the industry might want to do. We work on these problems collaboratively. We see the results of our work right away, it’s not just a research paper.”

The projects are funded in part by the Ontario Greenhouse Vegetable Growers association.

Print this page