Features

Heating

Structures & Equipment

Winter efficiency: Curtains, boilers and coverings

Energy is one of the greatest costs to greenhouses, especially in the winter. Here are three key areas to check out to see what is or isn’t working.

January 14, 2019 By Dr. Chevonne Carlow

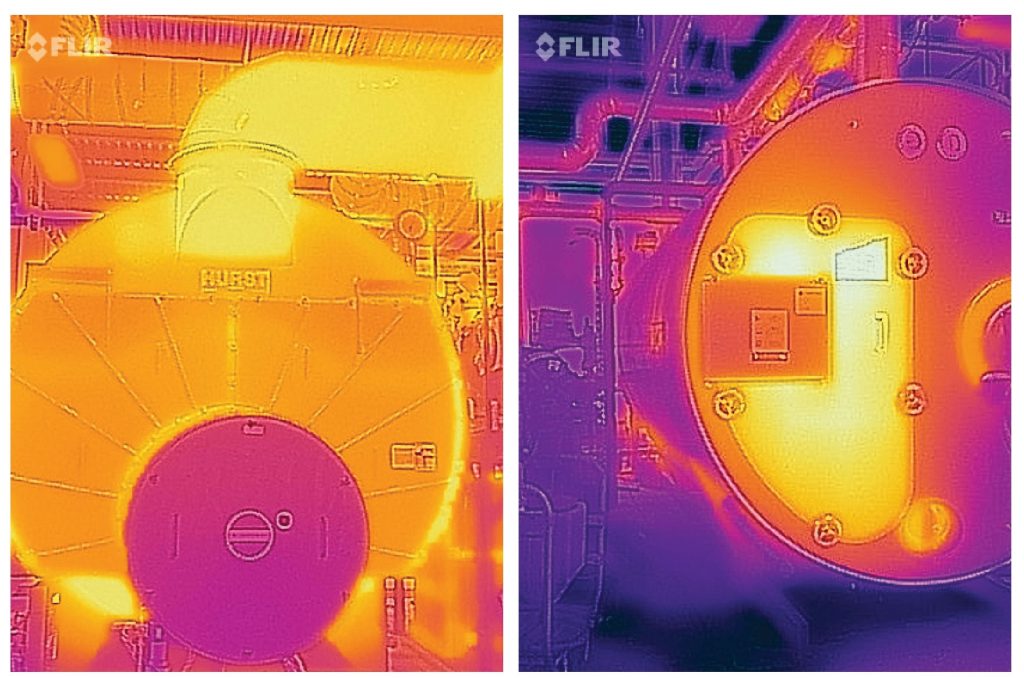

Older style boilers lose more heat compared to higher efficiency models Warmer areas are shown in orange, red and yellow hues.

Older style boilers lose more heat compared to higher efficiency models Warmer areas are shown in orange, red and yellow hues. Winter months in the greenhouse are a good time to see where your operation could be more efficient to save on energy, especially heating bills. Now’s the time to check out what is and isn’t working and what you might like to change for next season.

Three main areas to look at for improved efficiencies in the greenhouse are energy curtains, boilers and greenhouse coverings.

1. Energy Curtains

Energy curtains can have benefits all year round, but are best known for their insulating properties in the winter. Several different styles and materials exist, with varying levels of insulation and light transmission. Materials with greater insulating power have higher R-values and can help to lower heating costs. The right curtain (or curtains) for your operation will depend on what crops you grow and the level of control you would like over the climate in your greenhouse. In addition to overhead curtains, sidewalls and end curtains help to maintain a more consistent greenhouse environment around the perimeter and should be maintained.

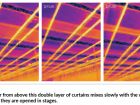

Multiple layers of curtains can increase the control you have over temperature and light levels in the greenhouse. Double layer curtains that open over the course of several stages in a staggered pattern provide better control over the speed with which cold air from above the curtain is allowed to mix with the warmer air below. Curtains that have light diffusion properties to help improve light quality in the greenhouse can be installed under curtains that control light emission or allow for blackout if needed, allowing for better control of light in and out of the greenhouse.

Regularly check for tears and holes in your curtains and ensure they are opening and closing easily. Be prepared to replace curtains as they age. Regular visual inspections and checks of your climate control systems settings will help let you know if the curtain is opening at the correct speed, and how the cold air above the curtain is mixing with the warmer air below.

2. Boilers

Boilers are a necessary part of heating a greenhouse, but they aren’t all created equal. Traditional firebox boilers have expected efficiencies of around 80 per cent, while high efficiency condensing boilers can have upwards of 95 per cent efficiency. A properly sized condensing boiler can also have the ability to fire at a lower output level, therefore causing fewer spikes and dips in the heating load while increasing efficiencies. High efficiency condensing boilers have a much larger upfront cost, but the increased efficiency will result in greater long-term energy savings.

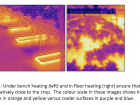

Consider targeting the majority of the heat to where the crop is located. Perimeter heating and ensuring snow melt from roofs are necessary parts of growing through Ontario winters. However, heated floors and under-bench pipes can help keep heat near the crop, making sure that the growing environment is best at crop level. Fans that circulate air throughout ranges can also help to create a more even growing environment.

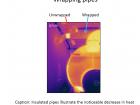

Maintenance and servicing of any boiler should be done on a regular basis. Upgrades to existing heating systems such as heat exchangers, variable speed boiler pumps, heat storage tanks and even simply insulating pipes can all help in gaining efficiencies.

3. Greenhouse Coverings

Take a look across the greenhouse floriculture industry and you’ll see a wide variety of greenhouse covering materials. Glass, polyethylene film and various types of polycarbonate are all used for various purposes and crops. Some growers like the control that glass gives them, others prefer the energy savings of double-walled polycarbonate.

When choosing a new covering, a balance between good light transmission and heat insulation is needed. This balance may differ depending on which crops you grow and when in the year. For example, some glass and poly materials can be made in a way to improve light diffusion, which may provide additional benefits. Certain acrylic materials are able to allow UV into the greenhouse, creating an environment that’s protected but has lighting that is more similar to an outdoor field. As with energy curtains, covering materials with greater insulating power have higher R-values and can help lower heating costs.

It’s also good practice to ensure that coverings are well-fitted around pipes, vents and gutters to avoid gaps where heat can easily escape the greenhouse. Try to replace ripped loading dock curtains and weather stripping around doors promptly. Keeping an eye on these seals may also help increase your biosecurity.

Upkeep is key

Overall, it’s important to remember that proper upkeep and maintenance (including scheduled replacement) is necessary to see efficiencies. Scheduling the opening of curtains or cycling of boilers only works if your climate control system is correct; so be sure to check how they operate and adjust as necessary! Knowing the energy savings you expect to see from a more efficient boiler or upgraded greenhouse covering is important to determine if the payback period on an investment is right for your business.

Interested in how the images for this article were obtained? We used a heat-sensitive camera. Warmer areas can be seen in shades of red, orange and yellow, whereas areas that are cooler are in purple and blue. A relatively inexpensive attachment for your smartphone ($500) and the free FLIR One app are all you need to check out your greenhouse in this way too! Thanks again to the greenhouses that allowed us to take these images.

Chevonne Carlow, PhD, is the greenhouse floriculture specialist at OMAFRA. She can be reached at chevonne.carlow@ontario.ca

Print this page