Features

Business

Trends

TO RECYCLE, OR NOT TO RECYCLE?

January 24, 2008 By Stefan Richard Dr. Youbin Zheng and Dr. Mike Dixon

A survey on the status of nutrient solution recirculation in Ontario was conducted between 2000 and 2002. The goals were to determine how extensively nutrient recycling systems were used in Ontario’s greenhouse industry and also to understand the problems that growers have encountered or are concerned about.

A survey on the status of nutrient solution recirculation in Ontario was conducted between 2000 and 2002. The goals of this survey were to determine how extensively nutrient recycling systems were used in Ontario’s greenhouse industry and also to understand the problems that growers have encountered or are concerned about. The data collected from this survey have established baseline information for the industry. This will allow us to establish reference points with respect to the deployment of nutrient recycling systems and to better focus our future research efforts to meet the needs of the greenhouse industry while responding to environmental concerns. Several years have passed since the initial survey but we feel that the responses of the growers still represent one of the most comprehensive studies available and show the greenhouse industry to be a proactive and environmentally conscious community.

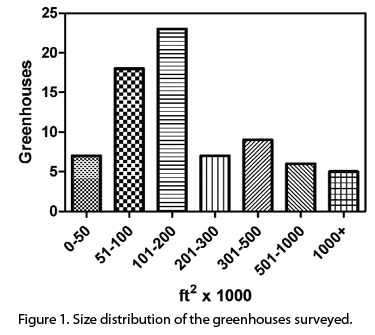

In this survey, we randomly selected and site-visited 75 greenhouses (19,512,000 square feet of greenhouse area; see Figure 1 for size distribution), which included 56 floral plant growers and 19 vegetable growers. The greenhouse area surveyed accounts for approximately 12 per cent of the total vegetable greenhouse area and 25 per cent of the total floral greenhouse area in Ontario.

In this survey, we randomly selected and site-visited 75 greenhouses (19,512,000 square feet of greenhouse area; see Figure 1 for size distribution), which included 56 floral plant growers and 19 vegetable growers. The greenhouse area surveyed accounts for approximately 12 per cent of the total vegetable greenhouse area and 25 per cent of the total floral greenhouse area in Ontario.

The following represents a brief summary of our findings.

Area of greenhouse under nutrient recirculation:

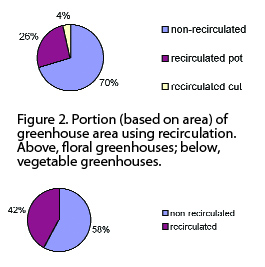

Almost half of the surveyed vegetable greenhouses used nutrient solution recirculation, however, 70 per cent of the floral crop greenhouses did not (Figure 2).

Figure 2. Portion (based on area) of greenhouse area using recirculation. Above, floral greenhouses; below, vegetable greenhouses.

History of application of recirculating techniques:

The average period that the greenhouses visited have used nutrient recycling was 5.7 years, ranging from 0.75 years to 25 years.

Individual management strategies:

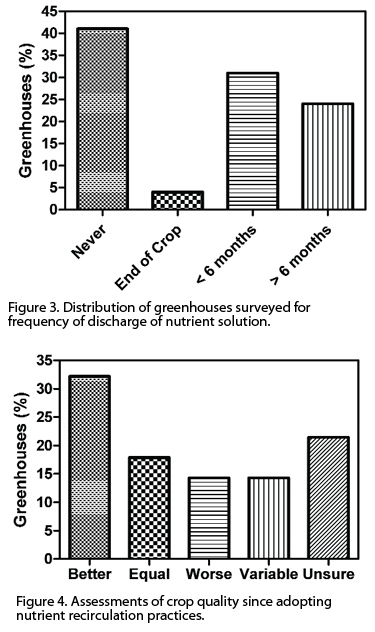

Of the growers that recirculate their nutrient solutions, 41 per cent never discharged their solution, four per cent discharged after each crop, 31 per cent discharged periodically every six months or less, and 24 per cent discharged periodically after six months (Figure 3). This includes one greenhouse that has been recirculating for 15 years and has never dumped a nutrient solution, and one grower who discarded his nutrient solution every two weeks in the summer and up to every two months in the winter.

Quality control of nutrient solutions:

Forty per cent of floral crop growers visited, who recirculated their nutrient solution, manually adjusted their solutions. They measured the EC (electrical conductivity) and the pH of their recycled solutions up to three times per week and added nutrients and watered as needed.

Sixty per cent of flower growers visited, who recirculated their nutrient solution, used automated systems to adjust their solutions. These systems adjust the nutrient and water content of the solutions based on automated sensing of EC and pH of the solution. Nutrients and water are added until the EC and pH of the solution reach pre-programmed values. These systems used two methods to add fertilizer to the solution: injection of concentrated nutrients directly in-line as water goes to the crop or for premixing in a storage tank prior to sending the solution to the crop.

Quality and yield of recycling systems:

Quality and yield of recycling systems:

Thirty-two per cent of growers reported increases in crop quality and yield since adopting nutrient recycling systems Figure 4. Eighteen per cent of growers reported no change in crop quality and quantity. Fourteen per cent of growers reported a decrease in quality and yield. Another 14 per cent of growers reported variable changes in quality and yield. These changes were dependent upon the given crop being grown. Twenty-two per cent of growers were unsure of changes in quality and yield specifically due to the adoption of nutrient recirculation. These growers changed other cultivation practices at or near the same time they adopted recirculating practices and this confounded their assessments.

Problems due to nutrient recycling:

Growers that use recirculating systems in their greenhouses were asked to list problems associated with the recirculation. They cited the following problems:

• Disease control (33 per cent).

• Nutrient ion imbalance (22 per cent).

• Growth media (15 per cent).

• Temperature control (15 per cent).

• Management (11 per cent).

• Salt accumulation (<5 per cent).

• Algae (<5 per cent).

• Life of troughs (<5 per cent).

Opinions of growers that did not recirculate:

In an attempt to assess the perception of recirculation among growers that did not use recirculating systems, they were asked to provide their opinions on the advantages and disadvantages of nutrient recycling. They cited the following:

Advantages:

Reduce fertilizer usage (34 per cent).

Reduce water usage (22 per cent).

Better for environment (16 per cent).

Labour savings (13 per cent).

Improved crop quality (4 per cent).

Ease of management (4 per cent).

Disadvantages:

Disease (34 per cent).

Cost of initial setup (33 per cent).

Difficulty of management (16 per cent).

Nutrient ion imbalance (3 per cent).

Less growing area (3 per cent).

When we asked the growers who were using recirculating systems how long it took to recover the cost of initial setup, they agreed on about five years.

Water source:

Water sources used by the growers visited include municipality water (57 per cent), wells (31 per cent), collected rainfall (25 per cent), collection ponds (20 per cent) and other sources (8 per cent – trucked in water, lakes and streams).

Water usage:

The annual area-based water usages are listed in Figure 5. For vegetable greenhouses, the annual water usage per area was more than two times higher under no recirculation than that under recirculation; and for floral crop greenhouses the annual water usage per area was close to eight times higher under no recirculation than that under recirculation.

Fertilizer Usage:

Fertilizer use was calculated using nitrogen input in the cropping system throughout the year. For floral crop production, the annual fertilizer usage was 242.4 Kg of N/hectare under recirculation, and 881.2 Kg of N/hectare under no recirculation. For vegetable production, the annual fertilizer usage was 680.2 Kg of N/hectare under recirculation and 3257.0 Kg of N/hectare under no recirculation.

Areas of nutrient recycling that require more research:

When growers were asked to comment on what areas of nutrient recycling required more research, the following issues were cited:

• Disease control (39 per cent).

• Insect pest control (11 per cent).

• Accurate and affordable in-line individual ion control sensors for nutrient solutions to avoid ion imbalance (7 per cent).

• Biocontrol (7 per cent).

• Nutrient-growth media interactions (media buffering of salts) (4 per cent).

• Pesticide registration (4 per cent).

• Salt accumulation (4 per cent).

Acknowledgement: The survey was financially supported by Flowers Canada (Ontario), the Ontario Centres of Excellence (CRESTech) and Environ-mental Canada. We thank the growers for their support, and appreciate the input from Wayne Brown (OMAFRA) and Shalin Khosla (OMAFRA) during the survey.

Stefan Richard, Dr. Youbin Zheng, and Dr. Mike Dixon are researchers at the University of Guelph. Their main research interests are greenhouse crop production and advanced life support. For more information, please contact Dr. Zheng at 519-824-4120, ext. 52741, or yzheng@uoguelph.ca.

Print this page