Features

Efficiency

Energy

Technology to re-use water an infinite number of times

July 17, 2012 By Treena Hein

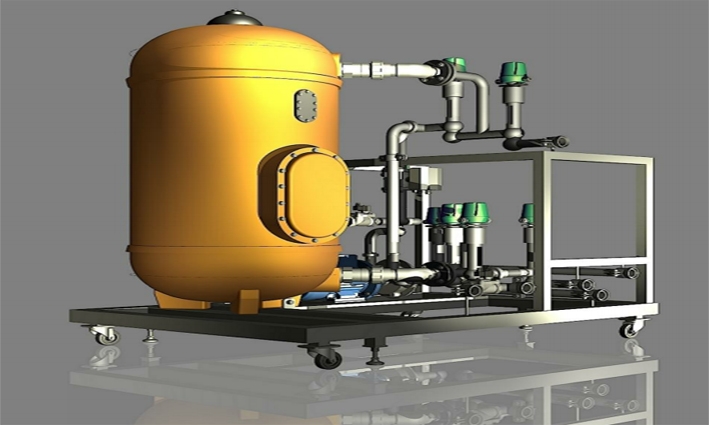

Depicted is Water IQ's Opticlear water filtering technology, part of the HTC project at Floriade 2012 World Horticultural Expo.

Depicted is Water IQ's Opticlear water filtering technology, part of the HTC project at Floriade 2012 World Horticultural Expo. It is currently possible to re-use water several times to irrigate plants in a greenhouse, but technology that will allow water re-use an infinite number of times is almost here – one of many technologies being showcased at the High Tech Greenhouse 2020 project (part of the Floriade 2012 World Horticultural Expo in the Netherlands).

In the Floriade 2009-2012 ‘Change’ Report, writer Tomas Grootveld describes closed-loop water conservation technology developed by the Dutch company Water IQ. Water IQ specialises in making filters for the food and beverage and the horticultural industries, and was one of the first companies to join the HTG project.

Grootveld writes:

Great amounts of water are wasted in current greenhouse irrigation processes, says Water IQ owner Freddy Dekkers. “There is a system within reach in which filters can take out all pollution from the water meaning no water is wasted at all. Furthermore, this prevents fertilisers from spreading into the environment.” Modern filters also make it possible to extract substances from the water that decelerate the growth of plant roots. This can help increase the productivity of the plant.

The High Tech Greenhouse project (HTG) contains innovations for every aspect influencing the growth process of the plant. Smart ventilators provide better climate control in the greenhouse. A new system for temperature and humidity control in the greenhouse uses less energy than conventional systems. This system also helps to reduce moulds and diseases.

“The greenhouse we are trying to create can almost think for itself,” says Dekkers. “We are trying to combine all available knowledge and make it easy to control.”

Role of the grower?

One of the most sensational innovations in the HTG is the GPS-guided quadrocopter. It can measure each plant’s growth, temperature and humidity. These data are directly sent to a computer. Together with other integrated systems, it can then take measurements concerning water, nutrition and temperature. The aim is to fly this device throughout the greenhouse without a horticulturist having to control it manually.

Less exciting but at least as effective is the use of double glazing in the HTG. Conventional

greenhouses use single glazing, which is quite poor at insulating. The risk of using double glazing, however, is that the greenhouse can become too warm and moist. The new system of climate and humidity control can solve this problem.

Integrating all these innovations into a properly working complex is called system integration.

All this leads to the following question: will there still be a role for the horticulturist in the greenhouse of the future? “What we are doing with these new techniques is automating the eye of the master,” says Dekkers. We combine all knowledge and experience in techniques that accurately monitor the condition of the plants, 24 hours a day, 7 days a week, from up close or from a distance. This is impossible for a horticulturist to do. With these new techniques we can monitor plants from a distance and take the right measures when needed.”

But how do you convince a conventional horticulturist to switch to a decentralised method of horticulture? “The main argument is that there will be a decrease in the use of raw materials and an increase in output,” says Freddy Dekkers. “And current horticulture is pretty high-tech. Especially important is the integration of systems.

This means growers have to work with computer technology even more. The challenge for technicians is to make innovations interact mutually, make them simple to apply and easy to operate.” Obviously investments are needed in order to build new greenhouses with double

glazing and to establish new water purification systems. The result, however, is a win-win situation. The output is greater because of an increase in efficiency and water is used optimally, with none wasted. The use of fossil fuels is cut by 30%, which saves the horticulturist a substantial amount of money.

Background of the High Tech Greenhouse 2020 (HTC)

The HTC is an innovative and energy-efficient greenhouse design being created by the ‘Floriade Innovation Cluster,’ which consists of many Dutch and German companies and many leading research institutes. Cluster members are incorporating and integrating many individual innovations in this new production design.

The High Tech Greenhouse 2020 addresses the major future food production challenges like urbanization, scarce space, scarcity of resources like fossil fuels, water, minerals, and the increasing consumer demands in terms of functionality and quality of products. It incorporates:

– Increased energy efficiency

– Use of renewable energy sources

– CO2 utilization from biogas

– Closed water system

Energy efficiency techniques are being be tested and validated in experimental full-scale greenhouses located at ‘Sunny Tom Tomatoes,’ ‘Kleve’ and ‘Georg Hanka Gartenbau’ in Germany and the Netherlands.

A concept version of the HTG will be built in Limburg, near the Floriade grounds. A second HTG will be constructed in the German city of Kempen. The project will continue until 2014 to ensure enough time to measure and analyse results.

HTC Project partners

Floriade 2012 – Lead partner

Companies

ISIS-IC GmbH – Sensor development

Elektro Limburg BV – Installation techniques

Grodan (Rockwool Benelux Holding BV) – Substrates and irrigation

Hoogendoorn Automatisering BV – Automation and control

Vostermans Ventilation BV – Ventilation

Pentair Haffmans BV – CO2 from biogas

Intelli-labs Deutschland Ltd. – Gas sensors

Patron AEM BV – Climate control

Water IQ BV – Water treatment and irrigation

Phenospex GmbH – Growth scan sensors

Doppelbauer Anlagentechnik – Heating systems

Knowledge institutes

Hochschule Rhein-Waal – Remote control development and biomass development by light

Wageningen University & Research Centre – Growth modelling

Hochschule Niederrhein – CFD modelling and flying sensor platform navigation

TNO – System integration applied research

Forschungszentrum Jülich GmbH – Plan-oriented control modelling

This material, written by Tomas Grootveld, first appeared in the Floriade 2009-2012 ‘Change’ publication.

Print this page