Features

Lighting

Structures & Equipment

Are you lighting for optimum plant growth?

When light is insufficient, it could hinder crop development and yields. Find out how much light is needed, how to measure existing light levels and the amount of light missing from your operation.

October 2, 2018 By Dr. Abhay Thosar

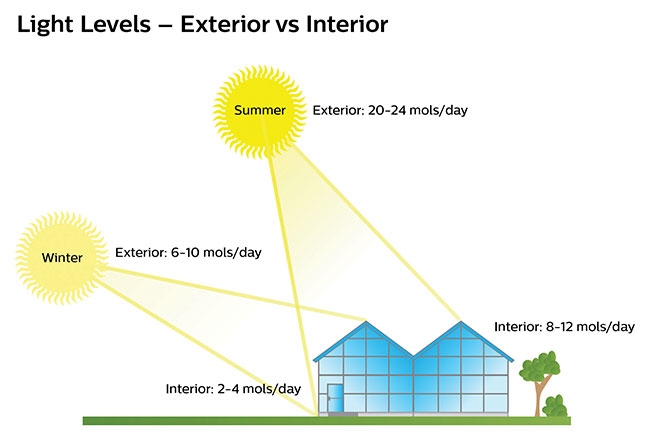

This greenhouse sunlight illustration shows the challenge of winter growing as the sun sits lower on the horizon.

This greenhouse sunlight illustration shows the challenge of winter growing as the sun sits lower on the horizon. Light is a prerequisite for photosynthetic activity for all crops whether the crops are grown in an open field or grown under cover. When light is insufficient, healthy plant development is hindered, which manifests in a variety of crop issues including poor root development, susceptibility to diseases and pests, stunted growth, delayed flowering, stretch, and low transplant viability.

In contrast, the delivery of optimal light – either natural or artificial – results in faster flowering, strong root development, improved plant structure and better yields. With the development of LED lighting technology, light can now be manipulated to enhance and improve plant growth and drive certain plant photomorphogenic responses. These light-induced changes are one of the key advantages to using new supplemental LED lighting technology.

Photosynthesis and Light

All crops need light for photosynthesis, which is the biochemical process by which carbohydrates are synthesized from water and carbon dioxide in the presence of light. Carbohydrates synthesized in this process are stored in the plant, then utilized for various processes. They’re channeled to the different plant parts based on activity and need. The requirement of carbohydrates varies based on a plant’s growth and developmental stage, as well as cultivar.

Crops can utilize any light that reaches the plant. However, to optimize crop production, growers should strive to supply optimum light levels to their specific crop or cultivar. When considering supplemental lighting for your greenhouse operation, it is important to evaluate the following four factors:

- Quantity (light intensity)

- Duration

- Quality (spectrum)

- Distribution (uniformity)

Determining optimum light levels

When we focus on the light requirement of plants, we consider photosynthetic active radiation (PAR), which is a measure of light between 400-700 nanometres.

The amount of PAR light that crops need for growth depends upon the crop and crop stage, and may vary slightly by cultivar. The optimal amount of light is known as the daily light integral (DLI) and is expressed as mol/m2/day. It measures the quantity of photons (in mols) hitting an area of one square metre over a 24-hour period.

Note: Foot candles and lux/lumens have been, and in some cases are still being used to measure light; however, both measure light that is detectable to the human eye and are not the best or most effective way to measure light for horticultural applications.

Below is a general guideline of DLI levels that support optimal growth for various crop categories:

- Bedding plants (seeded and un-rooted cuttings): 10-12 mol/m2/day

- Lettuce: 12-18 mol/m2/day

- Leafy greens: 8-12 mol/m2/day

- Tomato: 20-25 mol/m2/day

- Berries: 15-25 mol/m2/day

- Cannabis: 20-40 mol/m2/day

Once you know the optimum DLI for your crop, you can then begin determining the supplemental light needed.

Here is a scenario with Heuchera to demonstrate how to calculate the amount of daily supplemental light needed:

- Recommended DLI for high-quality Heuchera crop: 12 mols

- Light measured inside greenhouse at crop level: -5 mols

- Light deficiency or supplemental light needed: 7 mols

Mols and Micromoles

While DLI is a measurement of the quantity of photons over a 24-hour period, photosynthetic photon flux density (PPFD) is a measurement of the quantity of photons or light particles hitting an area of one square metre every second or simply stated as µmol/m2/s .

To determine your supplemental lighting needs in PPFD, the first step is to convert the supplemental light needed from mol/m2/day to µmol/m2/s and compare it to your measured light levels at the crop canopy level. The conversion would be:

(Target mols per day x 1,000,000) / (No. of seconds in one hour x No. of lighting hours)

Back to our scenario with the Heuchera crop. The crop will be lit for 18 hours; thus, the conversion is as follows:

(7 x 1,000,000) / (3600 x 18) = 108 µmol /m2/s

If the calculations seem a little too complex or complicated, be sure to work with a reputable lighting supplier or partner to help you with this calculation. In fact, your lighting supplier should work closely with you to measure light levels and then develop a customized light plan based on your crop challenges and business objectives.

Measuring light

Light transmission is affected by various structural factors including age and cleanliness of the glazing, as well as the infrastructure inside the greenhouse (e.g. baskets hanging above the bedding plant trays). It is suggested that you measure and validate the light transmission from the greenhouse glazing. First, measure the light levels outside the greenhouse and then measure the light inside the greenhouse at plant canopy level. Once transmission levels are verified through measurement, the daily accumulated natural light can be calculated using the software installed on the computer in your greenhouse (e.g. Argus, Priva, etc.).

Based on this number you can determine the deficit of mols/day that is needed from a supplemental light source. Calculate the quantity of light needed for the number of hours that you can run the lights. Once you have all these numbers you can more accurately evaluate your supplemental lighting options.

To accurately measure light, it is important to use a light meter that measures in µmol/m2/s. I do not recommend using light meters that measure in foot candles or lux. As mentioned earlier, foot candles and lux/lumens, while still being used by some in the horticultural industry, are measurements of light that is only detectable to the human eye and therefore, not an effective way to measure light for horticulture applications. For example, deep red and far red are not detectable to the human eye but they play a very important role in photosynthesis.

Selecting your supplemental light source

For some greenhouse operations, the application of high-pressure sodium (HPS) is not a feasible option since the electrical infrastructure of the greenhouse is a limiting factor. In addition, running HPS lights for 18 hours may be cost prohibitive.

Due to higher efficiency and lower power consumption, LED lighting allows growers to deliver optimum quantity as well as quality light for a longer period while managing electrical costs.

When evaluating different lighting options, it is essential that your lighting supplier prepare an accurate layout and lighting plan. The light distribution is important for the consistency of the young plants. Also, it is as important to measure the light levels after installation to ensure the light levels are as projected in the light plan. If there are “hot spots” or more intense zones under the supplemental lighting, these will be challenges for a grower regardless of the grower’s skill or knowledge.

During such situations when the grower knows the limitations, it would be good to look for other supplemental lighting options. The investment cost for LEDs may appear to be higher initially, however, there are calculations available where the grower can look at the return on investment from an electrical standpoint, comparing it with traditional lighting over time versus the initial capital expenditure.

Another important thing to consider is the effect of specific wavelengths on the photomorphogenic response of the plants compared to the plant’s response under traditional lighting. These plant responses can be quantified (e.g. higher yields, more blooms) and used in payback or ROI calculations.

In my next article, I will share information about the quality of light, the effect of different light spectrums on crop growth, and the benefits observed in the plants through our research with growers and research facilities.

Abhay Thosar, PhD is a senior plant specialist with Signify (formerly known as Philips Lighting). He can be reached at

abhay.thosar@signify.com.

Print this page