Features

Handling Systems

Structures & Equipment

Robots get a grip

January 2, 2012 By Samantha Beattie

Robots could be poised to emerge as a revolutionary technology for the Canadian greenhouse industry.

Robots could be poised to emerge as a revolutionary technology for the Canadian greenhouse industry.

|

|

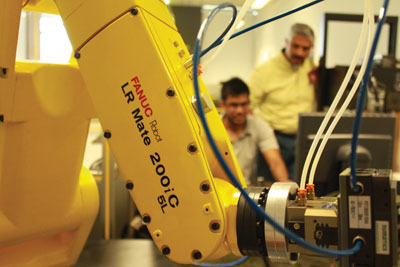

| Prof. Medhat Moussa is adapting an industry-standard robotic arm for greenhouse crops. PHOTOS BY BRUCE SARGENT/SPARK Advertisement

|

By largely replacing humans, these robots have the potential to decrease labour costs, improve market product quality and enhance the supply chain. Some say robots may just be what Canadian growers need for a competitive edge in a rapidly growing industry.

At the University of Guelph, Professors Medhat Moussa and Hussein Abdullah, from the School of Engineering, are creating what they call the Guelph Intelligent Greenhouse Auto-mation System (GIGAS), with input from Leamington vegetable greenhouse growers.

GIGAS, paired with a robotic manufacturing arm, can identify and pick ripe tomatoes, as well as perform de-leafing and pruning operations. After testing a first prototype last year, Moussa tested a second prototype with increased functionality this past summer.

With a one-metre reach, GIGAS mimics a human arm as it moves to pick greenhouse produce, such as a tomato. A special “gripper” replaces the hand. It’s composed of three aluminum and steel “fingers” that move in a pinching motion.

By closing on the stem and twisting, the gripper removes the tomato from the stem’s natural breaking point without damaging the plant.

Three palm-sized cameras that pick up both visible and infrared light are responsible for identifying and guiding the arm and gripper to the tomatoes that are ready to be picked.

Besides this gripper, the Guelph team is developing several other attachment tools that a greenhouse grower can individually use for other crucial greenhouse tasks such as de-leafing or pruning.

“If you design something that is very advanced and will fit all the different tasks like a human hand does, it would be too expensive,” says Moussa. “One way to get around this problem is to design different fixtures so each one is less complex and less expensive.”

DESIGNING ROBOTIC UNITS TO HARVEST, DE-LEAF AND PRUNE

The researchers hope that by performing harvesting, de-leafing and pruning in a timely and efficient manner, GIGAS will reduce waste and be better than manual labour at selecting tomatoes that are ready to harvest.

|

|

“It’s a small margin of time when the tomato is not ripe but not completely red,” says Moussa. “If the worker misses this point and comes back the next week or so, it is already too late and the tomato is spoiled for the market.” With its colour and infrared cameras, he says GIGAS could actually be better than a human eye at examining tomatoes.

GIGAS also improves tomato quality because it prunes and de-leaves the tomato plants so they grow in the best way possible. It also removes tomatoes that are too small, before harvesting the rest.

Ultimately, Moussa says GIGAS could help position Canadian growers as an increasingly reliable, attractive source of produce for buyers. He believes the robot has the potential to fill a large niche – the Canadian greenhouse industry grows by up to 10 per cent every year. (According to Statistics Canada, the industry had total sales of $2.5 billion in 2010.)

IMPORTANT TO CUT LABOUR COSTS

At the same time, the intensive manual labour required for greenhouse production is extremely expensive in Canada, with wages contributing as much as 30 per cent to the cost of production. To stay competitive with the U.S., where labour is cheaper, Canadians need to find an economical way to produce greenhouse commodities.

And GIGAS has this potential. If it operates less expensively, it could replace manual labour costs by up to 70 per cent.

Now, it’s on to field work. Moussa and his team plan to test GIGAS outside of the lab at a small test bench in a greenhouse on the University of Guelph campus. This summer, they aim to try GIGAS in commercial greenhouses.

“Part of our plan is to actually test the robot in the field to confirm it is able to do exactly what it is supposed to do,” says Moussa. “This is where the complexity is, where plants are stacked 50 centimetres from each other and there all kinds of cluttering and different lighting conditions.”

Moussa says GIGAS must differ from other, similar research efforts in efficiency and cost structure. “We are trying to address both of these aspects in our development,” he says. “That’s what the industry needs.”

This research has been funded by the Ontario Ministry of Agriculture, Food and Rural Affairs, and the Ontario Centres of Excellence.

Samantha Beattie is a student writer with SPARK (Students Promoting Awareness of Research Knowledge) at the University of Guelph.

Print this page