Features

Handling Systems

Structures & Equipment

Rolling out the robots

March 20, 2013 By Dave Harrison

Robotic technologies developed in the auto sector are now driving innovation in horticulture.

Robotic technologies developed in the auto sector are now driving innovation in horticulture.

And regardless of whether you’re talking about car plants or plants of a potted variety, the goal is to boost efficiencies and reduce labour costs.

|

|

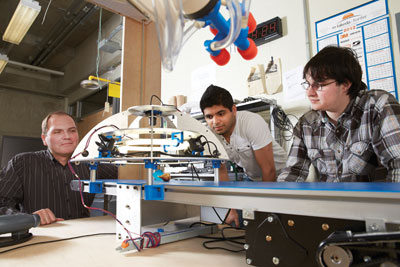

| VRIC’s John Van de Vegte, with Koshy Mathews and Alexandru Stan of Harvest Robotics, checks multi-camera scanning system. photos by Daniel Banko/bankmedia

|

Labour is a significant cost for greenhouse growers – about 30 per cent of annual operating expenses, according to Statistics Canada. Growers are looking for new ways to control costs, and automation is the key.

Help is on the way.

Thanks to a major grant of $2.5 million from the federal government last year, through its FedDev Ontario Prosperity Initiative, a leading edge Robotics and Automation program has been established at the Vineland Research and Innovation Centre.

“With investment from FedDev Ontario’s Prosperity Initiative, Vineland has brought together partners in technology and automation from non-agricultural sectors to address labour efficiency issues, one of horticulture’s largest challenges,” said Dr. Jim Brandle, CEO at VRIC.

He was commenting last April when the grant was announced.

“This is innovation working at its best,” added Brandle, “with new partners and proven ideas to address some of the unique planting and harvesting challenges that are common to our industry.”Created in 2009, FedDev Ontario supports the southern Ontario economy by building on the region’s strengths and creating opportunities for jobs and economic growth. A number of initiatives have been funded to help the region compete in the global economy.

Heading the program is John Van de Vegte, a mechanical engineer who spent many years developing robotics systems for the Canadian auto sector.

“We can transition a lot of the technology that already exists,” he says. “Custom automation and robotics have been used in the automotive industry for many years.”

Being able to tap into that technology – Ontario is a world leader in robotics and automation in manufacturing – is proving to be a big assist with the horticulture program.

Many of the systems that worked well in auto manufacturing can be redesigned for use in greenhouses, fields, orchards and mushroom barns, Van de Vegte explains.

But there are major challenges. Fruits, vegetables, mushrooms and flowers are quite delicate, and need different gripping systems, for example. Different sensors are often required, such as the need to select mushrooms based on certain size requirements, or the need to rotate tulip bulbs for planting.

GROWERS HELPING STEER RESEARCH PRIORITIES

■ While Van de Vegte and his team bring the technical expertise and key automation partners, local growers are keenly involved in helping with the design of the system, providing feedback on what exactly is needed by the industry.

|

|

| VRIC’s John Van de Vegte

|

Among those helping with this input is Sunrise Greenhouses (potted plants) and Pioneer Flower Farms (bulb crops). Both companies have long histories of innovation and market success.

“It’s their production expertise being combined with our technology expertise.”

Sunrise and Pioneer are also being used to trial and optimize the new equipment, to help researchers get the bugs out. “It’s important to run the equipment with a lot of volume.”

Grower participation ensures the team is on the right track. “It’s been so important to have representation from growers from day one, letting us know exactly what we have to build.”

CGC DEMONSTRATIONS LAST FALL DREW LARGE CROWDS

■ Visitors to last fall’s Canadian Greenhouse Conference enthusiastically viewed demonstrations of the automated potted plant transplanting and bulb planting equipment.

The feedback was all positive. “Some of them wanted to know where they could buy one,” he said.

They’ll have to be patient. The prototypes are working well, but more testing is required before these systems will be featured in sales brochures.

The VRIC program has three components at present:

- Planting: utilizing robots, vision systems and other automation to plant tulip bulbs and seedlings.

- Harvesting: developing vision-guided robots to harvest mushrooms.

- Packaging: using robots to label and package potted plants according to specific orders.

In addition to providing lower labour costs and improved efficiencies, the units will need to be priced at levels that ensure a relatively quick payback for the investment.

To date, most of the automation equipment used in horticulture is brought in from Europe. The Vineland program is about to change that in helping incubate a new industry in Ontario. Intellectual property resulting from its work will be retained in the province.

“There’s no reason we can’t one day be selling machines in Europe,” says Van de Vegte. “We have the capability here, and in many cases our cost structure is lower.”

The program is just scratching the surface of what can be automated in horticulture. Grower input will help drive future R&D into other tasks requiring a lot of labour.

“We need to continue to focus with growers on where the research priorities need to be.”

| GIGAS veg crop unit undergoing field trials A second major greenhouse robotics program in Ontario – this one with more of a vegetable focus – has been underway, the past few years, at the University of Guelph. Engineering The research is being funded by the Ontario Ministry of |

Print this page