Features

Growing Media

Inputs

Special Series in the rootzone #10: Improving input efficiency

May 28, 2012 By Andrew Lee

A steerable substrate with a focused irrigation strategy, combined with recycling of the drain water, can significantly help reduce input costs as well as enable compliance to environmental emission laws without affecting yield and quality.

Changing weather conditions impact massively on water uptake by the crop and therefore directly impact on the amount of irrigation water that is required (Greenhouse Canada, December 2009).

To allow the grower to exert total control of the rootzone environment, most substrates are now engineered so that WC and EC can be steered accurately, while at the same time using water and fertilizer efficiently. In this way, day level EC and WC can be managed according to the prevailing weather conditions, plant balance and energy input into the greenhouse (Greenhouse Canada, April 2010).

However, as with all things horticultural, there is no “magic button” that you can press to ensure success, you need an overall plan which meets both marketing (size and quality) and production (kg/m2) goals (Greenhouse Canada, June 2010).

The plan should be robust enough to enable the crop to cope with extreme temperatures and facilitate strong and regular growth even in the darkest periods of the year. With the support of the climate computer and measuring tools such as the water content meters, informed decisions can be made in respect to the (irrigation) strategy to steer the crop on a daily basis (Greenhouse Canada, September 2010). The benefits that this knowledge can provide and how it can be used to improve the financial returns to the company by optimizing fruit quality were subsequently addressed in an earlier article (Greenhouse Canada, October 2010).

In this article, I will outline how growers can become more efficient at using water and fertilizer by recycling the drain water using current technology. I will also provide some useful tips on how mundane operations such as cutting and positioning of the drain hole can impact significantly on substrate functionality and water use efficiency.

HOW MUCH WATER AND FERTILIZER DO YOU USE AND WHAT DOES IT COST?

■ Most growers can tell you exactly how much they spent during the last cultivation cycle on labour and energy, but very few can actually tell you directly how much irrigation they applied per hectare and what it cost. The cost can be significant.

The average water use for a tomato grower using stonewool substrate in Europe is approximately 1.25 m3/m2 per year (2.85 mL per joule) with 25 per cent drain (0.312 m3). The cost of fertilizer is close to $0.69 Cdn/m3/EC unit. With an average EC of 3.0 mS, the total cost to the grower in this example would be

$2.62 /m2 or $26,200/ha.

MANY ADVANTAGES TO RECYCLING DRAIN WATER

■ In the previous example, recycling the water would reduce the fertilizer bill to $0.65/m2. This excludes disinfection cost, which for a Priva UV Vialux system is approximately $0.21/m3.

Recycling the drain water in a “closed system” should therefore be a “no-brainer,” simply based on the cost savings that can be made. In addition, recycling also presents a “positive company image” and will most likely play a significant role in any company’s external sustainability message towards its customer.

Water, of sufficient quality, is already a scarce resource even in areas of northern Europe where the annual rainfall is abundant. However, greenhouse growers can be proud of the fact that they already use water more efficiently compared to open field production. Greenhouse operations recycling their drain water in the Netherlands consume approximately 15 litres of water per kilo of fruit produced compared to 60 litres of water per kilo of fruit in an open field situation in southern Spain.

As always, it is important that you use water as efficiently as possible. This can only be achieved through good irrigation management practices, drain water collection and recycling systems.

Do not underestimate the importance of the substrate. This should be of uniform quality, allowing you to steer WC and EC accurately. Key functionalities are the ability to steer water content on a low day level (40-45 per cent1) in winter and a higher level (75-80 per cent1) in summer, while at the same time being able to change or refresh EC quickly in periods of changeable weather (1Range indicated is for a dual density stonewool slab).

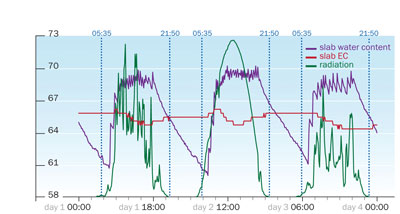

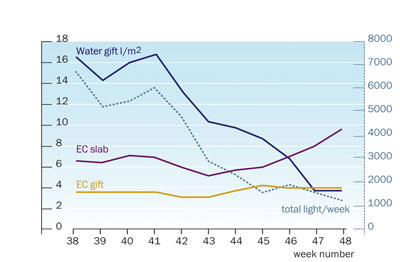

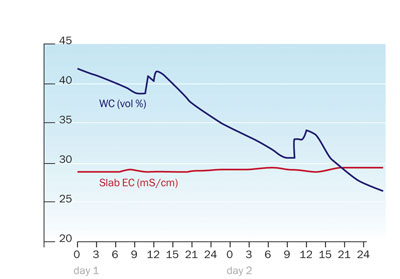

In this respect, the climate computer should allow you to implement flexible irrigation settings (Greenhouse Canada, September 2010) in combination with providing good graphics (Figure 1), as this will enable you to make informed decisions regarding any necessary adjustments to the settings on the computer.

|

|

| Figure 1: Advised standard graphic to illustrate the development of WC and EC in the substrate in respect to incumbent weather conditions. |

ENVIRONMENTAL LEGISLATION PRESSURES ARE GROWING

■ Growers worldwide are also coming under increasing legislative pressure related to the emission of water and nutrients from the greenhouse, particularly in the countries making up the European Union and more recently closer to home in Ontario.

Within Europe, the Dutch government has gone one step further, due largely to the concentration of horticultural holdings, and announced the “Kaderrichtlijn Water, 2010” (“Water Directive, 2010”).

In essence this directive has the goal of realizing zero emission of fertilizers from greenhouses by 2027. The goal is extremely ambitious and will not be achieved unless technological advances in nano filtration, in-line ion measurement and precision dosing technologies can be commercialized.

However, there are many things that can be implemented today based on current technology to help reduce environmental emission, even if legislation is not yet forcing the issue, notably:

- Adequate rainwater storage (i.e., a pure source of water with no Na+ contamination) in northern Europe based on an annual rainfall of 800 mm (80 m3/ha) dictates 500 m3/ha.

- Adequate drain water storage in Europe specification dictates 40 m3/ha.

- Accurate application of water and fertilizer:

- Accuracy within the distribution system, i.e., uniformity dosing equipment and drippers.

- Re-using first flush. (First flush describes water emitted from the substrates following the action of cutting the drain holes.)

- Minimal drain per cent during the cultivation with more accurate steering of WC and EC in the rootzone combined with regular monitoring and adjustment of nutrient levels.

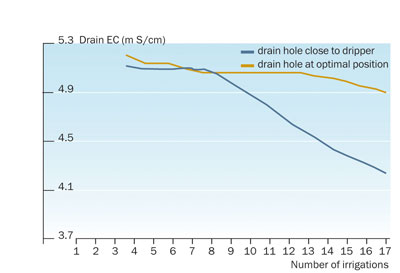

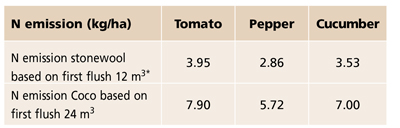

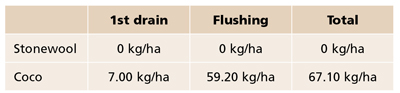

Table 1 illustrates the levels of emission reduction that can be achieved with drain water recycling and implementation of a structured irrigation strategy to minimize the drain volume.

|

|

| Table 1: Theoretical emission on N (kg/ha) from commercial greenhouses. (Data assumes a water application of 1,250 l/m2 with an average N application during the cultivation 18 mmol/L.) |

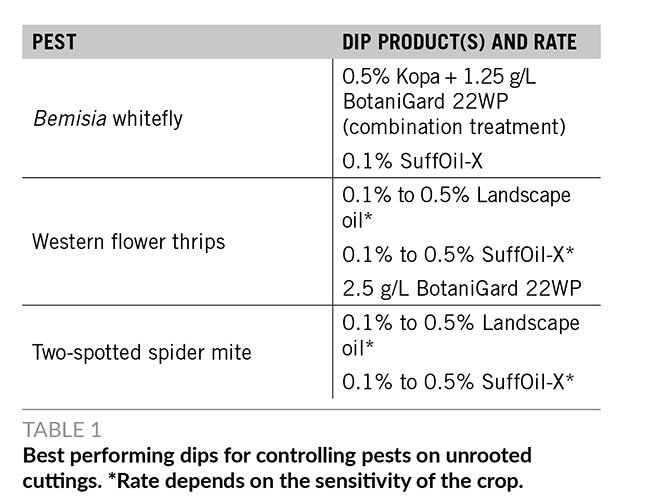

In Holland, a survey of 46 tomato growers by Guus Meis (LTO Glaskracht) found that the average N (nitrogen) emission was 115 kg/ha, which is very close to the figure of 85 per cent reuse and 25 per cent drain. There are a number or reasons why with current technology drain is still required (Table 2).

|

|

| Table 2: Reasons to run to waste during the production cycle.

|

INITIAL SATURATION OF THE SUBSTRATE

■ At the start of the cultivation cycle, stonewool is saturated with a complete nutrient solution. The drain holes are then cut and excess nutrient solution drains from the slab. A standard slab configuration (133 x 15 x 7.5 cm) will require 15 litres of nutrient solution for complete saturation, with approximately 6,000 slabs per hectare. This equates to 90 m3/ha water and fertilizer.

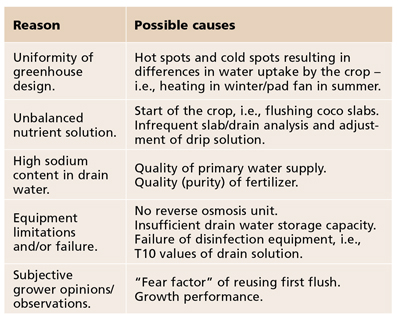

For maximum steering in the WC control range for your chosen slab type, it is advised that you cut one drain hole per 133 cm slab length (see text box tips for drain hole cutting). This should be cut at the lowest point in the slab and be ideally positioned at least 20 cm from the nearest dripper.

|

|

| Drain hole positioning example a. | |

|

|

| Drain hole positioning example b. |

This will allow maximum irrigation efficiency; i.e., it will generate minimal drain volumes while providing excellent EC refreshment in the slab (Figure 2).

|

|

| Figure 2: Effect of drain hole location to the proximity of the dripper on EC in the drain solution. A higher drain EC equals higher irrigation efficiency as more substrate solution is replaced. |

Tips for drain hole cutting and positioning

- One drain point is required per 133 cm slab. For slabs longer than 133 cm in length, one or two drain holes can be cut, based on the preference of the grower. Please note more drain holes will make it harder to resaturate the water content in the slab in spring. Also, more drain will be required to level the EC in the slabs.

- The closest distance between first dripper and drain hole defines the water behaviour in the slab. The greater the distance, the more refreshment and resaturation can take place in the slab.

- The cut should be made at the lowest point at the end of the slab in the direction of the slope. In case of an uneven profile, extra drainage holes will be required, once the slabs have settled at the lowest point. Never make the drainage holes directly below a propagation block or irrigation pin.

MANAGING EMISSION AT THE START OF THE CROP

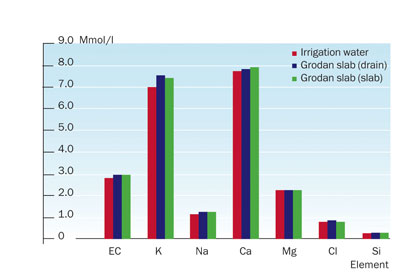

■ When the drain holes are cut, approximately two litres of drain solution will be realized (12 m3/ha). Most stonewool is chemically inert – as such, what you apply in the drip is what you receive back in the drain (Figure 3a).

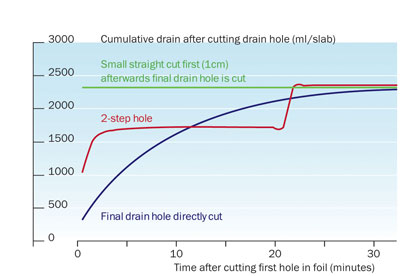

If this solution is allowed to run to waste it can result in significant emission, particularly N to the environment (Table 3). In some circumstances, one reason for not recapturing 100 per cent of this solution is that the drain volumes created can cause the hanging gutters to overflow. If this is the case, the drain holes can be configured in two stages (Figure 4) to manage the flow.

|

|

| Table 3: N emission (kg/ha) from first flush using standard feed recipes for tomato, pepper and cucumber. ( * Only if first flush is allowed to run to waste.)

|

However, it is perfectly safe to reuse the first flush from most rockwool slabs, provided that the drain basin is free of chemicals used during the cleanup of the old crop, a strategy that would result in zero emission (Table 4).

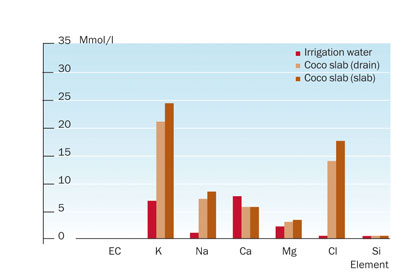

Conversely, our research indicates that with a like-for-like substrate volume, coco realizes twice the initial drain volume, i.e., 24 m3/ha and therefore twice the N emission based on the application of the same nutrient solution (Table 3).

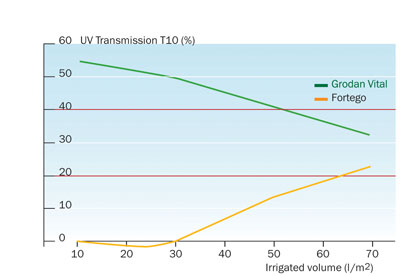

However, as coco is not chemically inert, the drain solution is not balanced (Figure 3b) and would require blending (EC 1.0 mS) prior to reuse. However, due to the tannin content in the drain solution, this is not possible (Picture 1b) as the T10 values are not at acceptable levels until at least 60 l/m2 (600 m3/ha) water has been applied (Figure 5), equivalent to the volume that would be required in the first eight to 10 weeks of a winter crop grown on stonewool.

|

|

| Figure 3a: Analysis of drip, slab and drain solutions during initial saturation of Grodan slabs. | |

|

|

| Figure 3b: Analysis of drip, slab and drain solutions during initial saturation coco slabs. | |

|

|

| Figure 4: Managing the flow of drain solution by two-stage cutting of the drain holes. | |

|

|

| Figure 5: Amount of flushing on coco required to achieve acceptable T10 values for effective drain water disinfection using a UV system. |

|

|

| Picture 1a: Colour of first flush from stonewool is clear, permitting immediate and effective use of UV sterilization systems, and therefore reuse of first flush. |

Picture 1b: Colour of first flush from standard coco is brown due to tannins. Use of UV sterilization is not advised due to inadequate T10 values. |

The potential difference in N emission during the first flush and flushing period of coco is huge (Table 4).

|

|

| Table 4: Potential emission (N kg/ha) from stonewool and coco slabs for a tomato based on volume of first drain and volumes required to reach acceptable T10 values for recycling the drain water. |

MANAGING WATER AND NUTRIENT SUPPLY DURING CULTIVATION

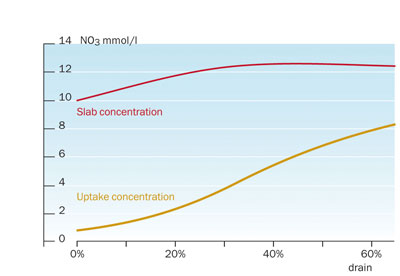

■ Emission reduction during the main cultivation period is achieved by recycling and working with minimal drain volumes (Table 1). Taking the example for a tomato crop further, it is also possible to reduce the N-NO3 levels in the initial feed solution to 8-10 mmol/L for a more “generative” start to the crop and then add 1 mmol/L per cluster until standard feed levels (16-18 mmol/L) are reached (Source, Groen Agro Control, the Netherlands).

However, it is only possible to impact the desired crop response if you structure the irrigation strategy to target zero or very low drain volumes in the initial weeks of crop development. This is due to the uptake concentration of N-NO3 (nitrate) by the crop; i.e., the more irrigation you apply (i.e., to flush the substrate) the more the crop lives from the drip solution and the effect of low N-NO3 feed minimized (Figure 6).

|

|

| Figure 6: Slab and uptake concentration of N-NO3 at different drain volumes. Source Groen Agro Control, the Netherlands.

|

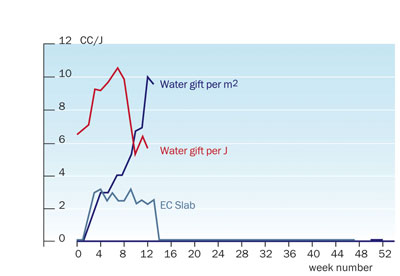

For winter-planted crops, the strategy would see the substrate EC increase and the WC fall (Figure 7); when the crop requires approximately 2.0 litres irrigation per day, the EC can be

stabilized at a lower level as first drain volumes are realized.

|

|

| Figure 7: Development of EC and water gift at the start of a winter planted tomato crop in northern Europe.

|

For additional information on how to structure an irrigation strategy to provide the level of control illustrated in Figure 1, please refer to the article “Water and EC management” (Greenhouse Canada, September 2010) remembering the key

triggers in the decision-making process, notably:

- Transpiration then irrigation.

- Drain by 400 J/cm2 or 600 W/m2.

- First drain in line with EC refreshment.

- EC refreshed and stable in line with global radiation during peak solar hours.

- Stop irrigation in relation to plant activity for a stable decrease in WC. It is also worth noting that on the dark days in winter, maximum rest time will drive the total volume of water you give (assuming start and stop are correct). The values provided in Table 5 are a useful indicator related to radiation (W/m2).

|

|

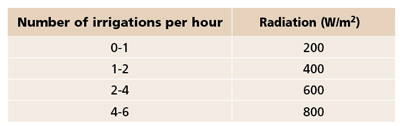

Table 5: Guides for maximum rest time settings in line with light intensity (W/m2). |

During the main cultivation period when the crop is growing quickly, it is also important to take regular analysis (seven to 10 days) of the slab and/or drain solution as the balance of nutrient elements will change quickly.

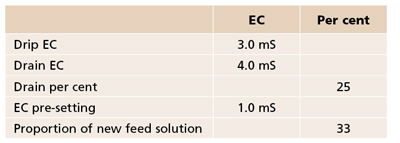

Regular adjustment will allow you to target fertilizer input more accurately and potentially recycle the solution longer. In this respect, remember that your drain may only be 25 per cent but that the drain solution may account for 33 per cent of the nutrients you apply, due to the EC pre-setting on the computer (Table 6).

|

|

| Table 6: Proportion of drip and drain solution used to irrigate the crop.

|

MANAGING EMISSIONS AT THE END OF THE CROP

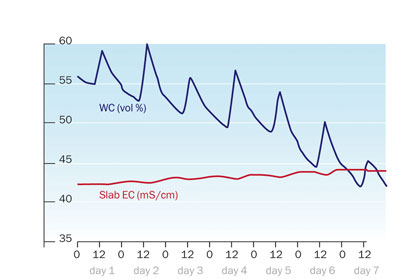

■ Continuing with the example of the tomato crop planted in winter, the goal is to have the drain basins empty by the end of the cultivation cycle, in effect using all the fertilizer you paid for. Implement the strategy about four weeks from the end of the crop (Figure 8).

Start by increasing the EC pre-setting to 1.5-2.0 mS so that you use proportionally more of the drain solution to provide the new feed and work on lowering the drain volumes by decreasing the slab WC. This will result in less solution coming back to the drain basins and they will gradually empty.

The reaction in the substrate will be lower WC and higher EC (Figure 9a and b). Fruit quality should not be affected as all of the remaining clusters will be in the ripening phase of their development.

|

|

| Figure 8: Managing drain towards the end of the crop. In this example the heads were removed in week 38. WC decreased and slab EC increased approximately four weeks from the end of the crop. |

|

|

|

| Figure 9a: Slab WC and EC are significantly reduced in the week prior to removal of the crop. | |

|

|

| Figure 9b: Slab WC is reduced to minimal levels before the end of the crop. This practice not only minimizes fertilizer use but also enables easier handling during turnaround as the slabs are lighter. |

SUMMARY

■ This article has highlighted the cost to the business of water and fertilizer and how these inputs can be minimized via drain water recycling. Sustainable growing means minimizing water and fertilizer input while maximizing output and quality. To move towards totally closed systems will require technological innovations that are currently not commercially viable.

However, recycling from day 1, working with a structured irrigation strategy and frequent nutrient analysis during the cultivation cycle to reduce the volume of drain required, will all help minimize the environmental impact in the short term.

Print this page