Features

Energy

Management

Screens

Structures & Equipment

Saving energy with curtains: A simulation exercise

Using simulation models, greenhouse operators can predict energy use and cost savings by selecting different types of energy curtains, tailored to their greenhouse operations.

January 11, 2022 By Robert Hanifin

All images courtesy of Ludvig Svensson

All images courtesy of Ludvig Svensson Greenhouse climate screens, or curtains, were first introduced in the late 1970s as a means to conserve greenhouse heating fuel in the midst of that decade’s energy crisis. Their technology, appearance, and functionality in greenhouse climate management have all greatly diversified since then, but their single largest use in northern climates remains achieving greenhouse energy savings through trapping heated air beneath them. Common greenhouse energy saving curtains used widely in Canada today run the gambit from transparent curtains that allow high light transmittance in the winter for various vegetable crops, to blackout curtains used for abatement of supplemental lighting or for photoperiod control, as well as curtains with nearly every level of shade in between for ornamental crops and other specific greenhouse crop needs.

Most new glass greenhouse construction projects within Canada and the northern United States include a minimum of one energy saving curtain, if not multiple curtains. This is necessitated by the relatively lower insulation value of glass versus other greenhouse covers. Greenhouses covered with inflated double-poly, polycarbonate, and other materials are increasingly including curtains in their construction as well. This is as the energy savings of curtains, as well as their overall importance in managing greenhouse climate, are becoming more widely understood. However, some new greenhouse construction of alternative glazing materials, as well as many older structures, still continue to forego curtains.

Certain trends in greenhouse technology are also increasing the popularity of double curtain installations. This is the case with greenhouse supplemental lighting, which has caused a rapid expansion in the use of blackout curtains for light abatement, aided in part by new, restrictive bylaws in some areas aimed to curb light pollution from greenhouses.

Throughout Canada and the northern U.S., energy saving curtains help greenhouse growers conserve heating fuel and save money. Utilizing multiple energy saving curtains across different crop types significantly increases energy savings in most northern regions, and also gives the greenhouse grower greater flexibility in managing their climate. Although every greenhouse offers a unique production environment, the energy benefits of single and multiple curtains can be simulated with specialized modeling software. It combines greenhouse parameters with real world climate data to estimate the energy needed to heat a simulated greenhouse. The remainder of this article provides examples of such modeling exercises.

Within each scenario, the energy calculator tool is utilized to simulate the energy savings gained by using curtains in one-hectare vegetable greenhouses, with different covers, differences in supplemental lighting and in different parts of Canada. In other parameters the greenhouses are the same (e.g gutter height, use of natural gas heating, etc), and common temperature setpoints and curtain control setpoints are used for the different crops. In each scenario, the energy saved by utilizing one or two curtains is compared to a reference of not having a curtain present in the greenhouse. A description of each scenario is followed by a graph and table of the energy savings, along with some explanations.

Note that these scenarios were created for comparison purposes. Each one is accompanied by a table presenting the results in numerical format. Specific values in energy savings will differ depending on the curtains used. Each scenario notes the screen models that were used as examples.

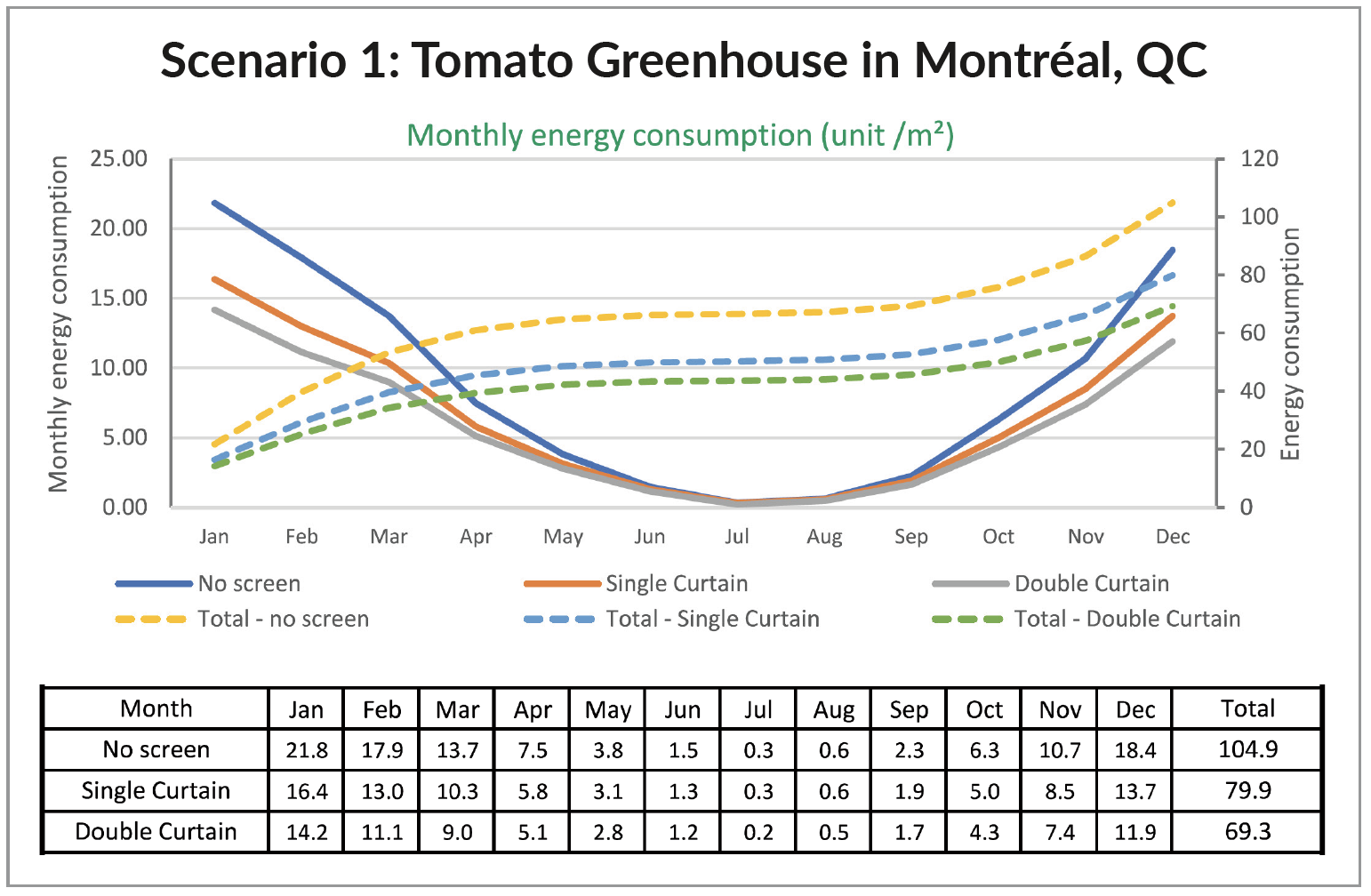

Figure 1. Model showing natural gas use (m3gas/m2 greenhouse space) in a tomato Venlo glasshouse with supplemental HPS in Montréal, Que.

Scenario One: Tomato, supplemental HPS, Venlo glasshouse, Montreal, QC.

The graph compares the monthly (solid lines) and running annual total (dotted lines) of natural gas consumption for a tomato greenhouse in Montréal lit by HPS lamps. The solid blue line and yellow dotted line serve as the reference with no curtain/screen. The solid orange line represents the level of natural gas consumption with a single transparent energy-saving curtain. The gray solid line indicates the pairing of the single energy saving screen with a light abatement screen, resulting in lower energy consumption out of the three options.

Based on this model, a single energy-saving curtain reduces natural gas consumption over a year-long growing cycle by 24 per cent; using two energy-saving screens in this scenario reduces energy consumption by 34 per cent. In the latter example, one of the curtains being a light abatement blackout curtain shows that these curtains are capable of significantly contributing to greenhouse energy conservation.

Curtains tested in model: Svensson Luxous 1147 FR for the single curtain option. Svensson Luxous 1147 FR and Obscura 9950 FR W for the double curtain option.

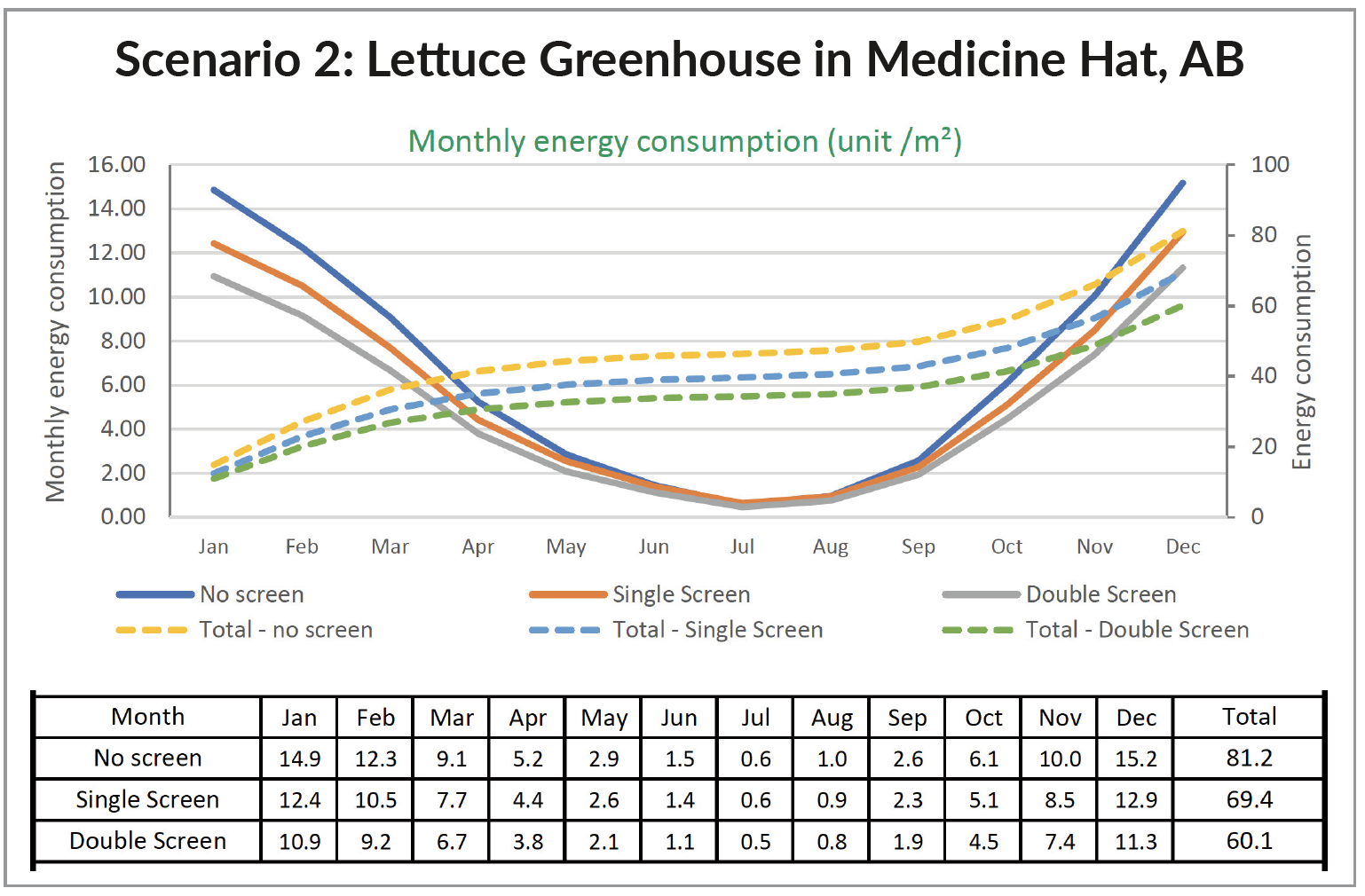

Figure 2. Model showing natural gas use (m3gas/m2 greenhouse space) in a lettuce double-poly greenhouse with supplemental LED lighting in Medicine Hat, AB.

Scenario Two: Lettuce with supplemental LEDs, double-poly greenhouse, Medicine Hat, AB.

In this scenario, an inflated double-poly greenhouse is equipped with LED lamps for supplemental lighting. By local ordinance on light abatement, such a greenhouse would likely need to utilize a blackout curtain. In the double curtain example, the blackout curtain combined with a transparent energy saving screen once again leads to higher energy savings. When compared to no curtain use at all, the amount of natural gas consumed is reduced by more than 25 per cent using double screens. Using one single screen reduces natural gas consumption by over 14 per cent compared to no curtain use.

Curtains tested in model: Svensson Harmony 3647 FR for the single curtain option. Svensson Luxous 1147 FR and Obscura 9950 FR W for the double curtain option.

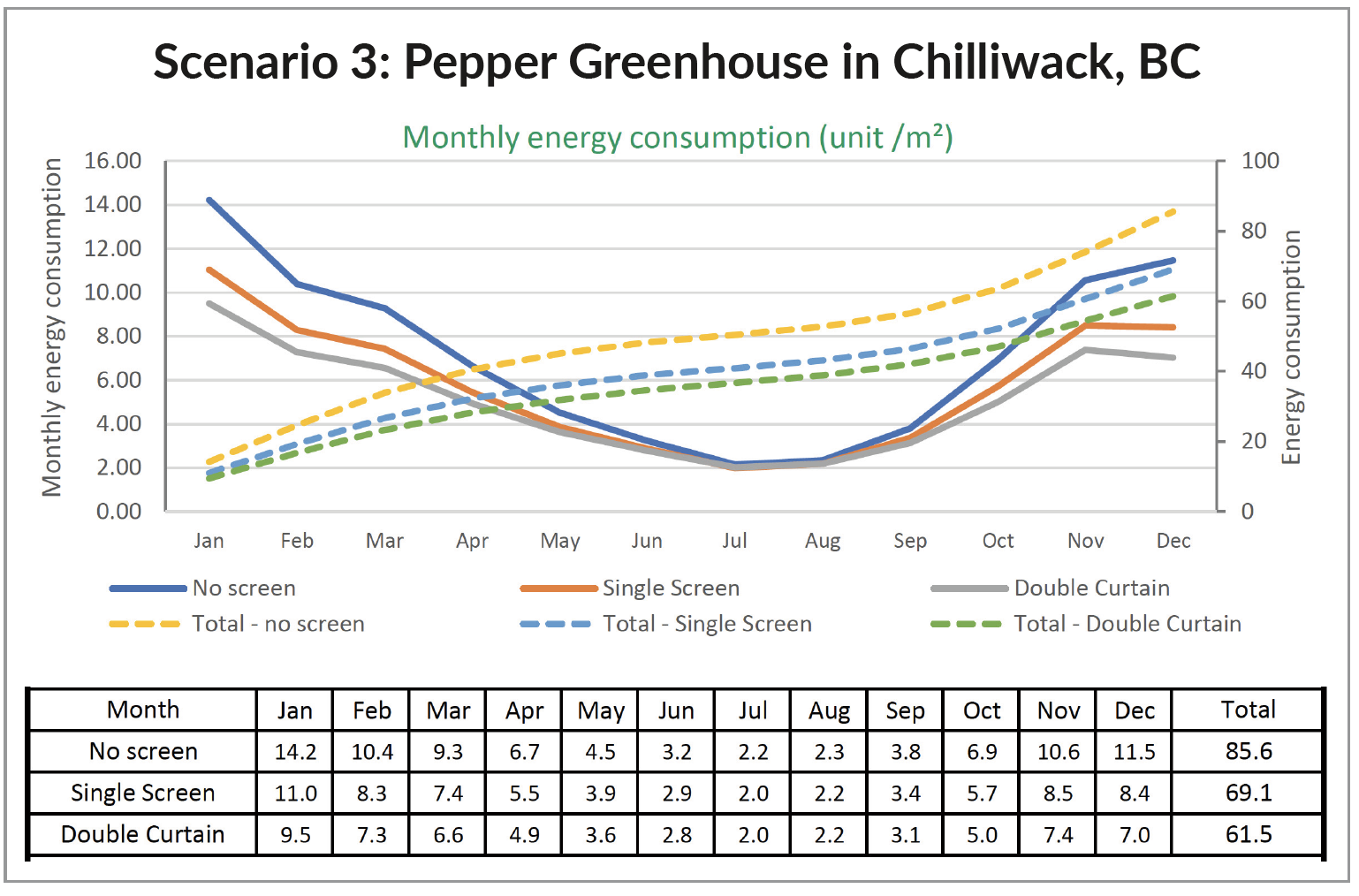

Figure 3. Model showing natural gas use (m3gas/m2 greenhouse space) in a pepper glasshouse with no supplemental lighting in Chilliwack, B.C.

Scenario Three: Peppers, no supplemental lights, glasshouse, Chilliwack, B.C.

In this scenario, the unlit sweet pepper greenhouse is equipped with one or two energy-saving screens. Use of a common energy-saving screen for single installations in peppers leads to a 19 per cent reduction in total natural gas use. The added second curtain provides for additional energy savings throughout the year, and in this particular case, was selected for light diffusion and shading in the summer months. The option for two energy-saving screens provides nearly 30 per cent reduction in natural gas consumption, compared with not utilizing any curtains at all.

Curtains tested in model: Svensson Luxous 1547 D FR for the single curtain option. Svensson Luxous 1147 FR and Harmony 2047 FR for the double curtain option.

Key Takeaways

The above scenarios capture only a fraction of the wide range of simulation models that can be made. Greenhouse location, physical parameters like size and glazing material, heating fuel, and type of curtain or curtains utilized can be customized in the modelling software for specific greenhouse projects. In addition, the cost of greenhouse construction and the cost of heating fuel can be introduced into the simulation to model the return on investment of a single or double energy-saving curtain systems. This is vital, as the cost must be justified to retrofit an existing greenhouse with additional curtains or to include a second curtain in a new greenhouse build. However, with the amount of added energy savings that can be realized, this is becoming an increasingly attractive option that also provides greater flexibility as an additional benefit to the grower, better overall control over their greenhouse climate, and compliance with light abatement regulations.

About the software

About a decade ago, greenhouse curtain manufacturer Ludvig Svensson developed an energy calculator tool that modeled greenhouse energy savings with different curtains. This was designed to help guide growers in selecting product for energy savings. This tool was subsequently incorporated into the Hortinergy platform (hortinergy.com), a simulation program utilized to model energy performance across greenhouse types. It combines user input on specific greenhouse parameters with real world climate data, providing a more accurate picture of energy consumption for heating in a simulated greenhouse anywhere in the world. Now, Svensson uses the energy calculator within a specialized version of the Hortinergy platform that incorporates the energy performance of the company’s energy saving curtains. Thus, the energy performance of closed structured, energy-saving curtains in any greenhouse can be simulated.

Rob Hanifin is a Greenhouse Climate Consultant for Ludvig Svensson and is based in the United States. Questions on greenhouse energy-saving simulations and curtains? Email him at Robert.Hanifin@ludvigsvensson.com.

Print this page