Features

Energy

Management

Special Series European trends #3: Cogeneration in the Netherlands

September 29, 2010 By Paul Hovius

In the previous two articles, the growing interest in carbon dioxide (CO2) fertilizing has already been discussed.

In the previous two articles, the growing interest in carbon dioxide (CO2) fertilizing has already been discussed. Particularly with vegetable crops and flowers, CO2 fertilizing will improve production. But while the use of CHP flue gases has advantages, it also disadvantages. In contrast to flue gases from a traditional boiler, flue gases from a CHP system contain a high concentration of nitric oxide (NOx). Where the flue gases of the traditional boiler can be used directly for CO2 fertilizing, flue gases from the CHP should be cleaned. Although new methods have been introduced, the standard method today is the use of a Selective Catalytic Reduction system (SCR).

|

|

| Cogeneration can be a major electricity supplier. Advertisement

|

In this article the basic features are described, along with the advantages and disadvantages.

Three suppliers for Selective Catalytic Reduction systems had been active for many years in the Netherlands, at a time when most CHP systems were owned by the electricity board companies. However, the profitability of CHP decreased over the years, and only one Selective Catalytic Reduction system supplier remained in horticulture in more recent years.

Beginning in 2000, the energy market in the Netherlands was liberalized and profitability increased for CHP systems. Growers started to invest in their own CHP systems.

To use flue gases for CO2 fertilizing, the motor should be installed with an SCR to remove the noxious NOx. There are now two competitive SCR system suppliers in the Netherlands.

The use of SCR systems in horticulture differs considerably from their use in industrial applications, in which the systems are needed to comply with environmental requirements. This means that a failure of the cleaning system is not so harmful. On the other hand, a failure in horticulture increases NOx emissions, which will damage the crop within a few hours. SCR systems for horticulture, therefore, should comply with more stringent safety features to avoid uncontrolled CO2 fertilizing with a high level of NOx. In our opinion, the choice of the SCR system and additional safety features are very important.

THE PROCESS OF SELECTIVE CATALYTIC REDUCTION

■ A box with catalytic material is placed directly after the motor. The SCR system operates best with a high flue gas temperature (approx. 400℃) out of the motor. Urea (mixture of water and ammonia) will be injected with a mixing pipe/nozzle. This is used because pure ammonia is very dangerous. The ammonia (NH4) will react with the NOx to create nitrogen (N2) and water (H2O).

NOx refers to nitric oxide and nitric dioxide emissions. In the past, the relationship between nitric oxide and nitric dioxide was based on a 2:1 ratio. Recently, measurements show that sometimes the relation is 1:1. The SCR was controlled and supervised only for the nitric oxide content in the flue gases. Because nitric dioxide is more hazardous to the crop than nitric oxide, as is the relationship of 1:1 instead of 2:1, the chance of exceeding the limitation value for crop damages is close without the response of the safety systems. Our company has worked with SCR suppliers to provide additional monitoring and safeguarding of the NO2 content in the flue gases.

Another issue is the amount of excess air in modern CHP. To comply with the environmental requirement for NOx, the modern motors are operated with a high level of excess air, which results in a high percentage of “rest oxygen” in the flue gases (dilution of the NOx) and the measured NOx in parts per million (ppm) is less. The total amount of NOx can be sufficient to damage the crop. The limitation in values in ppm of the NOx emission should be adapted for the “rest oxygen” content in the flue gases, whereby the CO2 valve must close (safeguard action).

CO2 FERTILIZING

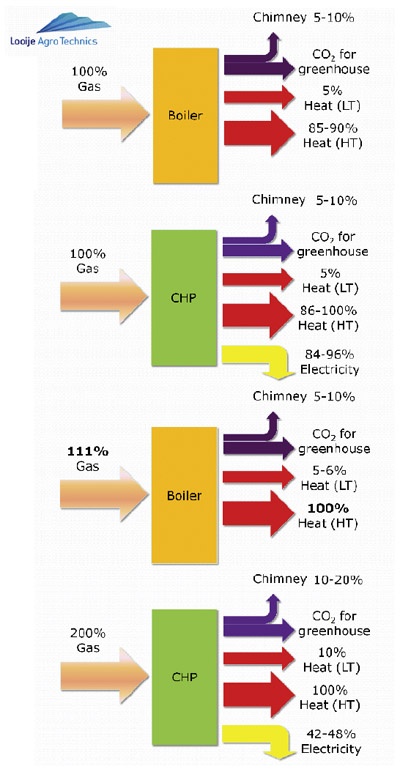

■ The flue gases will be cooled to 40-50℃ in the condenser. A higher temperature will damage the CO2 PVC distribution system in the greenhouse. The distribution system is connected to the chimney of the CHP and controlled by a motor-operated valve. This valve should comply with what’s required for horticulture applications. The advantage of CO2 fertilizing with a CHP is that approximately twice the amount of CO2 is available with the same production of heat compared with a gas-fired boiler. This is illustrated in the accompanying chart.

|

CO2 fertilizing with a CHP has advantages for the crop, including the increase in the production due to the extra CO2 availability. However, it is necessary to check the cropping requirements during the different steps from procurement until commissioning and during operation. ■

Paul Hovius is a senior energy consultant with Looije Agro Technics BV. For more information, call 949-690-3070, or visit www.lat.nl.

Print this page