Features

More for less: Lowering N, P and K in mums

Reduced nitrogen, phosphorus and potassium inputs lead to quality chrysanthemums.

December 14, 2020 By By Dr. Barry J. Shelp, Edward J. Flaherty, William J. Sutton, Skye Duncan Stephens, Alyna J. Donetz, Lou M. Schenck And Jamie Aalbers

Figure 1. Chrysanthemums were tested using three N/P/K delivery regimens. This photo shows 75V plants (75/22/75 up to bud break, followed by potable water for the remainder of the crop cycle).

Figure 1. Chrysanthemums were tested using three N/P/K delivery regimens. This photo shows 75V plants (75/22/75 up to bud break, followed by potable water for the remainder of the crop cycle). Closed subirrigation systems are popular in indoor floricultural production because they reduce nutrient usage and the risks of contaminating water resources with nitrogen (N), phosphorus (P), boron and molybdenum. However, the recirculated nutrient solution must be refreshed occasionally and eventually discharged or treated in accordance with applicable environmental legislation. Consequently, it is likely better to reduce nutrient delivery where possible so that even less fertilizer is used.

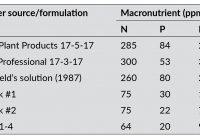

Based on supplier recommendations, general fertilizer practices for cultivating greenhouse pot chrysanthemums typically involve a complete soluble N/P/K fertilizer such as 20-10-20 at 300-400 ppm N with micronutrient amendments. For subirrigation in particular, research and industry recommend a lower fertilization rate that is often 25-50% less and reduced or eliminated during the final two to three weeks of the crop. Guidelines are not typically given for the other macronutrients (i.e., sulphur, calcium and magnesium), probably because they are often supplied in excess, as counter ions in the fertilizer formulation or in the limestone or dolomite used for pH adjustment of the pot medium.

Over the past decade, we investigated a nutrient delivery strategy that improves the macronutrient use efficiency of subirrigated pot chrysanthemums grown under research greenhouse conditions, without adversely affecting crop production or quality. Entire macronutrient and micronutrient supplies were removed during the reproductive growth stage, and 50% of the macronutrient levels in Sonneveld’s solution (in ppm: 260 N/80 P/235 K) were provided during the vegetative growth stage, together with the essential micronutrients. There were no visible signs of macronutrient deficiency, and plant/flower yields and quality were unaffected.

Subsequent commercial and research trials detailed here pushed the envelope even further, using approximately 75% less N/P/K than the industry standards up until bud break. These findings advance the development of our modified, low-input delivery strategy and validate the use of even lower macronutrient levels in producing subirrigated pot chrysanthemums.

Experimental set-up

In the commercial experiments, different N/P/K rates and delivery regimens were tested on pinched plants of three to four chrysanthemum cultivars at Schenck Farms and Greenhouses in St. Catharines, Ont. Experiments were conducted over two separate summers (denoted Schenck #1 and Schenck #2), using different N/P/K rates each time. Plants were individually grown in a peat moss:perlite mix (90:10 by volume, pH 6.0) using an automated open subirrigation system housed in a naturally lit greenhouse.

Three delivery regimens (N/P/K in ppm) were used in each experiment (delivered during V=vegetative stage and/or R=reproductive stage), depending on the year:

- 150VR = 150/59/322 or 100VR = 100/29/100 over the entire crop cycle (“control”);

- 150V = 150/59/322 or 100V = 100/29/100 up to bud break, followed by potable water during the remainder of the crop cycle; and,

- 75V = 75/30/161 or 75V = 75/22/75 up to bud break, followed by potable water during the reminder of the crop cycle.

The three delivery regimens were randomly assigned among three adjacent flood benches. Plants of all cultivars were arranged randomly at both ends of each bench.

To obtain a more rigorous assessment of the low-input delivery regimen, four separate research trials (UofG #1-4) assessed the growth of two pinched chrysanthemum cultivars with a single N/P/K rate (in ppm; 64/20/90), as well as ample macro and micronutrients delivered up to bud break only at the University of Guelph. The plants were grown in a peat:perlite mixture (50:50 by volume, pH 5.0-5.7) using an automated ebb-and-flow, closed subirrigation system housed in a naturally-lit research greenhouse.

Validation of low N/P/K inputs in commercial and research settings

The two commercial experiments (Schenck #1 and 2) supplied N/P/K levels as low as 25% of the levels found in historical and current fertilizers (see Table 1). There were no visible signs of nutrient deficiency in either experiment (Fig. 1).

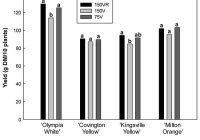

Regardless of the experiment and cultivar, supplying the lowest fertilizer rate during the vegetative stage only did not significantly decrease dry mass yielded from the shoots of the plants. There was no difference when compared to the highest fertilizer rate, whether supplied over the vegetative stage only or over both vegetative and reproductive stages (Figs. 2 and 3).

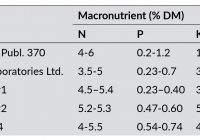

Analysis of the diagnostic leaf revealed that all cultivars grown in Schenck #1, except ‘Kingsville Yellow’, exhibited clear decreasing trends in leaf N, P and K levels as the weeks progressed. The N, P and K levels at bud break ranged from 4.5 to 5.4%, 0.23 to 0.60%, and 3.3 to 5.6% of dry shoot mass respectively, across all cultivars with the lowest delivery regimen. This shows that leaf macronutrient levels at bud break were considered sufficient, compared to recommended values found in the extension literature (Table 2).

Figure 4. UofG plants treated at 64/20/90 ppm up to bud break only.

In the four separate research trials conducted at U of G using the low-nutrient regimen, neither of the cultivars exhibited visible signs of nutrient deficiency, and the quality of the plant and flowers was excellent (Fig. 4). Across both cultivars and all trials, the leaf macronutrient levels at bud break aligned with values found in the extension literature (Table 2). These findings provide strong support for the use of relatively low N/P/K inputs up to bud break only in the production of chrysanthemum plants/flowers with high quality.

From validation to application

Many commercial fertilizer formulations are now available for cultivating greenhouse pot chrysanthemums (Table 1). Examples include Fusion Plant Products 17-5-17 (Plant Products, Ancaster, ON) and Peter’s Professional 17-3-17 (ICL Fertilizers, Dublin, OH), which contain all macronutrients but sulphur (Table 1). Sonneveld’s solution was developed in 1987 for flowers and vegetables; it contains N/P/K levels similar to those in the commercial fertilizers. Our previous nutrition studies on greenhouse-grown pot chrysanthemums, which used Sonneveld’s solution as the industry standard, confirmed that the production of market-quality plants and flowers were unaffected by removing the entire nutrient solution at bud break, and by supplying N and P levels as low as 130 and 40 ppm, respectively, during vegetative growth.

In this article, a combination of commercial and research greenhouse experiments demonstrated that even the lowest levels of N/P/K supplied (in ppm: 64-75 N; 20-30 P; 90-161 K) led to acceptable nutrient levels in the leaves (Tables 1 and 2). Furthermore, plant and flower quality at harvest remained consistent across a wide range of N/P/K supplied, indicating that the plant is able to use these macronutrients more efficiently with decreasing macronutrient supply up to bud break. If the macronutrient supply was not reduced or removed after bud break, even more macronutrients would be wasted.

As this research shows, macronutrient delivery to modern chrysanthemum cultivars can be further optimized by reducing their levels in the subirrigation solution by approximately 75% during vegetative growth. Our modified delivery practice provides chrysanthemum growers, fertilizer manufacturers, farm consultants and government advisors with the tools to reduce macronutrient usage, the volume of concentrated nutrient-rich solutions for management, and environmental contamination. Future research will focus on the use of essential micronutrients, especially boron and molybdenum.

Acknowledgements: This project is part of the Accelerating Green Plant Innovation for Environmental and Economic Benefit Cluster and is funded by the Canadian Ornamental Horticulture Alliance (COHA-ACHO) and by the Government of Canada under the Canadian Agricultural Partnership’s AgriScience Program. Industry partners include AgMedica Bioscience Ltd. of Chatham, Ontario, and Schenck Farms and Greenhouses of St. Catharines, Ontario. Thanks to Berger of Sainte-Modeste, Quebec, for supplying the uncharged pot mixture.

For more background, see the articles “Moving towards low-input floricultural operations”, and “It’s about time: Using phosphorus efficiently”, which are published, respectively, in the December 2018 and March 2020 issues of Greenhouse Canada.

Barry Shelp is Professor Emeritus, Edward Flaherty and William Sutton are technicians, and Skye Duncan Stephens and Alyna Donetz are graduate students in the Department of Plant Agriculture at the

University of Guelph. Lou Schenck is the owner and operator of, and Jamie Aalbers is the trial manager at, Schenck Farms and Greenhouses. For more information, please contact Dr. Shelp at 518-824-4120 ext. 53089, or bshelp@uoguelph.ca.

Print this page