Features

Efficiency

Energy

Management

Ventilation

Managing humidity and temperature with vertical air flow solutions

With vertical air flow fans, ventilation jets pull in cool, dry air from above the screen and distribute it in a vertical direction.

June 1, 2022 By Kyle Edmiston and Robert Hanifin

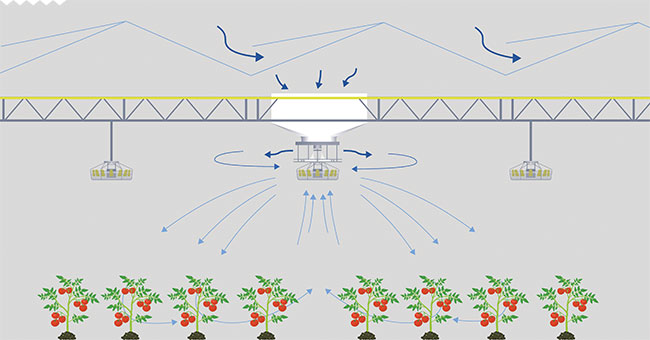

Demonstration of the use of vertical air flow to manage temperature and humidity. As shown above, the fan and jet pulls cool air into the greenhouse and distributes it evenly over the crop.

Demonstration of the use of vertical air flow to manage temperature and humidity. As shown above, the fan and jet pulls cool air into the greenhouse and distributes it evenly over the crop. Growers face significant challenges in maintaining a homogenous climate throughout the entirety of their greenhouse.

Screen gapping, running supplemental lighting paired with light abatement curtains and high density crops are all contributing factors to heat, humidity, and uneven climate zones within a greenhouse. To maintain even climate zones and plant growth, while also faced with rising energy costs, growers are looking to find adaptive ways to manage the greenhouse climate. An excellent way to maintain balanced temperature and humidity levels throughout a greenhouse is with vertical air flow (VAF).

VAF fans are a simple way to distribute air from top to bottom inside the greenhouse, as warmer air tends to stay at screen level. Furthermore, VAF fans provide more control in the distribution of air compared to horizontal air flow fans. By adding a jet component with the standard VAF fan, these systems pull in cooler, drier air from above the climate screen, and then evenly distribute this air in a vertical direction with the help of downward facing fans. This results in reduced temperatures and humidity.

As the area above the screen fluctuates in temperature based on outside weather conditions and vent position, VAF fans can be modulated to run at certain speeds to ensure the correct amount of air flow is distributed to maintain humidity and temperature levels. Connecting these jet and fan units to additional climate sensors gives the grower even more control over their grow space, ensuring that each area of the greenhouse has the right amount of control for an even climate.

Simon de Boer, head of plant production at Schoneveld Breeding states that a uniform climate is their number one priority when considering greenhouse design and production.

“Uniformity was one of the most important starting points.” says de Boer. “Everything stands or falls with a uniform greenhouse climate, especially in a breeding company. That was our number one priority. A plant that is on the back of the table must grow under the same uniform conditions as a plant that is in the middle or the front of the table. After all, inequality in climate or cold corners can have an effect on the results of the breeding. And that’s just not what we want. We want to let the genetics speak.”1

To achieve this, the potted-plant producer consulted with an expert to select the right combination of climate screens paired with vertical air flow jets and fans. This combination, which allows ventilation through closed climate screens, has allowed for temperature, humidity, and energy levels to be in balance with one another, resulting in a uniform climate.

De Boer is one of many growers in the Netherlands who has found success in climate management through the use of VAF fans and jets. The same technology is now available to growers in North America. VAF fans and jets can be utilized in a wide variety of greenhouse types in addition to venlo. They are compatible with different greenhouse glazing materials, as long as roof ventilation is available.While most common in larger, gutter-connected structures, they can be used in single frame greenhouses as well. There is no specific minimum gutter height that a greenhouse needs to have, but it is necessary that the crop height (especially in vine crops) is two to three metres below the fans to allow for full airflow. VAF fans and jets are relatively inexpensive to run. At $0.10/kwh, a paired fan and jet would cost less than $5 to run 12 hours per day for a week.

Many growers in the U.S. and Canada who could benefit from such technology still have not been exposed to it. The best course of action for implementing a VAF system into a greenhouse is to speak with an expert. Check with the seller of VAF equipment to learn what they offer in terms of assistance. VAF jets and fans are typically installed at a 1:2 ratio, with up to 20 jets per hectare for vine crops using supplemental lighting. Your chosen seller should be able to work with the VAF company to plan a layout specific to your greenhouse and crop.

Citations:

- Stöver, H., 2020. ‘Uniform climate is the number one priority for us”. [online] www.hinova.nl. Available at: <https://hinova.nl/wp-content/uploads/Schoneveld-Breeding-_-bloemisterij-editie-7-2020.pdf> [Accessed 12 April 2022].

Kyle Edmiston is the business development manager of the ClimaFlow division at Svensson. Robert Hanifin is a Svensson climate consultant.

Print this page