Features

Growing Media

Inputs

Special Series: growing in the rootzone #14

September 23, 2013 By Hans van Herk

Looking at key processes to ensure consistent saturation of plugs and blocks to ensure crop is off to a good start.

|

|

| Hans Van Herk checking young plants. Advertisement

|

In this second of four articles, Grodan® crop consultant and young plant specialist Hans Van Herk provides an insight into the world of high-tech tomato propagation and describes the importance of uniformity along the value chain and its impact for greenhouse production.

Uniformity in greenhouse production is a fundamental requirement. Every innovation and subsequent development is undertaken with uniformity in mind. Modern greenhouses are tall, built to a square footprint with no internal glass walls in order to create as uniform a climate as possible for plant growth.

Heating systems are designed to deliver heat uniformly and irrigation systems to deliver water uniformly.

Growers stopped using soil over 40 years ago to work with Grodan stone wool because of improvements in uniformity.

More recently, they’ve moved from laying substrate on the ground to hanging gutters.

Uniformity in propagation is equally important because, with the right plant specifications, a uniform batch of plants can be steered from the start of the cultivation for maximum production and quality, where all subsequent inputs such as labour, climate and irrigation can be optimized.

In this article the key processes for ensuring uniform saturation of plugs and blocks in order to increase the uniformity of usable transplants will be discussed.

Seed quality is naturally the starting point for uniformity in propagation. Delivered in small packages the seeds must be ready for germination when triggered by temperature and water. Breeders and seed companies are investing heavily in technologies to improve seed quality for the greenhouse industry.

Companies such as Incotech, based in the Netherlands, provide a comprehensive range of treatments to enhance the overall quality of a seed lot. These include fluid density grading and x-ray imaging as well as seed priming and pelleting to improve speed and uniformity of emergence, and most importantly for a propagator and grower, the number of usable transplants. Quality in terms of uniformity and number usable transplants is further optimized by substrate design and use.

From a physiological point of view, it must be remembered that germination occurs when enzymes and proteins are first mobilized within the seeds, long before the emergence of roots and shoots.

|

|

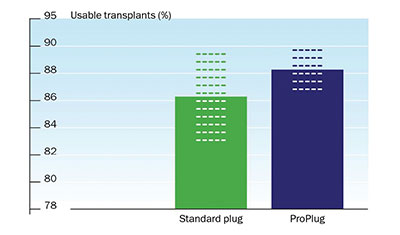

| Figure 1.0a: Percentage of usable transplants for Pro plug compared to standard stone wool plug.

|

|

|

|

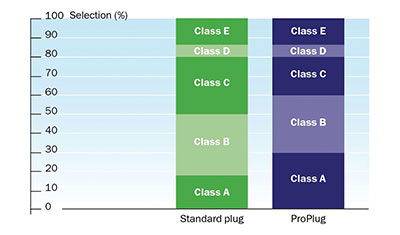

| Figure 1.0b: Grading classification of rootstocks between Pro plug and standard plug. For greater uniformity, more A and B grades are preferred at first selection. |

This physiological process requires oxygen so the seeding plug must have the correct air-to-water ratio.

For example, this aspect was fundamental in the design of the Grodan Pro plug. Using new Vision Technology this revolutionary new stone wool

facilitates better germination rates. Most importantly due to its new configuration and water characteristics, it results in stronger root development and greater plant uniformity, which for the propagator means more useable transplants per sowing (Figure 1.0a), and for rootstocks an increased percentage of A&B grades at first selection (Figure 1.0b).

Prior to sowing the seeding plugs are saturated for the first time. An EC of 1.2 to 1.5 mS/cm² and a pH of 5.8 is standard; however, if the pH of the primary water supply is too low, fresh water can be used. In these situations, the plugs should be flushed again with fertilized water three to four days after emergence.

It is important that the initial saturation of the plugs be performed correctly so that all seeds are surrounded by uniform WC and EC. However, the water should not be applied all at once. A wetting line containing three or four irrigation beams spaced 30 cm apart is the most efficient method to utilize.

Because it is important that a sufficient volume of water be applied, the belt speed and pressure should not be set too high. The applied water will then have the opportunity to move downwards along the stone wool fibres, ensuring complete saturation. An open belt that allows the water to drain away quickly further enhances this dynamic flow preventing air from becoming trapped inside the plug.

Weighing individual trays is a simple way to check if the plug trays have been correctly saturated. Trays with 240 cells should weigh between 2.20 and 2.40 kg.

|

|

| A wetting line for plugs with several irrigation beams will ensure uniform and complete saturation. |

|

|

|

| Seeds should fall into seed holes for uniform emergence and growth. | |

|

|

| Grafted tomato plant.

|

Sowing is normally undertaken using a vacuum drum seeder and subsequently the seeds should fall into the seed holes. The holes should be centred in the plug and free from loose stone wool. Seeds are expensive and should not miss their intended target. Following emergence, this will also allow the seeds access to a greater volume of stone wool resulting in more uniform growth.

After sowing, the seeds should be covered with an even layer of vermiculite and it is important to choose the correct proportion. Grade 3 will keep the seeds sufficiently moist but will also allow access to ample light and oxygen, which are essential for germination of tomatoes.

To further enhance uniformity of the graft union, young rootstock transplants are first selected approximately nine to 11 days after sowing, usually into four or five grades. This can be done manually, or more conventionally, by a machine. Using a machine increases efficiency for the propagator but requires a stone wool plug that retains its shape well as each tray may be selected two or three times. The young transplant should also be firmly anchored into the stone wool so that it does not fall over and become damaged during the selection process.

For single-headed grafted plants transplanting into blocks normally occurs approximately eight days after grafting. The blocks should initially be saturated in a similar manner to the plugs.

Preferably this should also be performed using a wetting line consisting of three or four irrigation beams spaced 50 cm apart. The speed of the belt is important and it should take approximately 40 seconds for the blocks to travel from one irrigation beam to the next. This will give the blocks adequate time to drain.

Look closely to see the water rise and fall in the plant holes as the blocks pass between the beams.

Of course there are other ways in which the blocks can be saturated. The underlying message is that for the best results, it is a process that should be repeated several times. To be sure the blocks have been correctly saturated, you can periodically weigh them. Ideally a 10 cm x 10 cm x 6.5 cm block must weigh 550 g, and a 10 x 15 x 6.5 cm block should be 825 g as it leaves the wetting line.

A deviation of plus or minus 25 g is acceptable; a greater deviation will often result in noticeable differences in growth.

Since the best transplants have been selected for placing in the blocks they will be stronger. Generative growth can be stimulated by initially saturating the blocks with a higher EC in the range 2.5 to 3.0 mS / cm2 and a pH of 5.6 to 5.8. Once rooted into the block, generative steering towards plant specification can begin.

Seed companies and seed technologists are constantly improving seed quality. Their efforts are targeted at increasing the speed and uniformity of emergence. Aligned with these developments, Grodan is developing substrates and knowledge targeted at increasing the uniformity of useable transplants. Uniformity can be improved within a seed lot if initial wetting of plugs and blocks is optimized. This ensures optimum WC and EC around the developing seedlings and transplants.

In the next article, I will go into more detail on the tools you can use to steer these young plants in propagation working towards a specific customer requirement. Increasingly, customers are looking for more generative young plants. This is due to the increasing cost of energy, which has prompted changes in climate management at the start of the crop in winter.

|

|

Hans van Herk is a young plant specialist at Grodan. • www.grodan.com

Print this page