Features

Crop Protection

Inputs

Greenhouse Grower Notes: November 2007

January 16, 2008 By Gillian Ferguson

Being keen on clean. Many pests and pathogens can survive poor conditions for a long time

A thorough cleanup between crops is essential if greenhouse vegetable growers are to stand a chance of managing pest and disease problems. The reason for this is the ability of many common pests and disease-causing organisms or pathogens to survive unfavourable conditions, and for a long time.

A thorough cleanup between crops is essential if greenhouse vegetable growers are to stand a chance of managing pest and disease problems. The reason for this is the ability of many common pests and disease-causing organisms or pathogens to survive unfavourable conditions, and for a long time.

Pests, such as the two-spotted spider mite and greenhouse whitefly, have mechanisms for withstanding very low temperatures. Pathogens, too, are particularly resilient because of the protection provided either by the tissue within which they reside, or by the resistant spores they produce. For example, infected air-dried tomato leaves infected with Tobacco mosaic virus can remain infective even after 24 years at laboratory temperatures. Another example is the canker-causing bacteria, Clavibacter michiganensis, which can survive within infected tissue for at least two years in dry soil, and as long as 36 weeks at -20ºC in non-sterile soil. Other examples include Pythium, Botrytis and Didymella bryoniae, the gummy stem blight causing fungus, which all produce thick-walled spores that can withstand long periods of very cold temperatures.

A list of steps needed to achieve a good cleanup is provided here as a reminder:

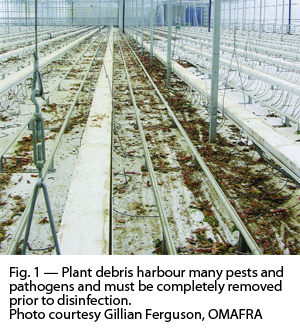

Thoroughly clean before disinfecting – Removal of all inorganic (e.g., calcium deposits) and organic residues (e.g., plant debris – Fig. 1) is a prerequisite for a good cleanup. Inorganic deposits can harbour pathogens, and as indicated above, plant debris provides protection to many disease-causing organisms. Moreover, organic residues can neutralize the effects of disinfectants by interacting with them. During the cleanup process, using lots of water applied at high pressure effectively removes much debris from surfaces. Such removal is very important because they can serve as sources of infection despite subsequent application of high concentrations of disinfectants. There is absolutely no substitute for proper sanitation prior to the disinfection process. It may be necessary to rinse surfaces with plain water between cleaning and disinfection, depending on the type of products used and the manufacturers’ recommendations.

Clean all surfaces – Many pathogens can survive for long periods on surfaces within the greenhouse. For example, studies indicate that when the canker-causing bacteria occur freely – i.e., not within plant tissue – on surfaces, they can survive on a plastic surface for about 17 weeks at 5ºC, and on a cement surface for about 30 weeks at the same temperature. Extra care is needed in cleaning such textured surfaces. Additionally, particular attention should be paid to elevated horizontal surfaces.

Studies indicate that many pathogens are lodged on rafters, window ledges, and on the tops of overhead piping, etc.

Note pH effects – Using high concentrations of different products in close succession may reduce effectiveness of products because of large differences in solution pH. As an illustration, soaps are alkaline and residues can either inactivate certain disinfectants, or reduce the effectiveness of those disinfectants that work optimally at an acidic pH. Bearing the influence of pH in mind, it is probably best to use one type of disinfectant if multiple applications of disinfectants are being made. As long as proper concentrations are used and sufficient contact times allowed, the disinfectant of choice should be effective. Note also that disinfectants are best applied to dry surfaces because wet surfaces dilute the concentration of the disinfectant applied.

Allow sufficient contact time with disinfectants – No disinfectant works instantaneously. Some contact time is required for maximum effectiveness, and the time required for contact is influenced by the temperature and concentration of the disinfectant. Generally, higher temperatures increase efficiency of disinfectants by two- to three-fold for every 10ºC rise in temperature, whereas lower temperatures do the opposite. For example, the effectiveness of chlorine is reduced by 50 per cent at 10ºC. Some other products, however, appear to be effective at temperatures as low as about 5ºC. Distributors and manufacturers should be consulted on this aspect of specific products.

Note hardness of water used for disinfection – Some disinfectants, par-ticularly quaternary ammonium compounds, are deactivated by hard water, i.e., water with high levels of calcium and magnesium.

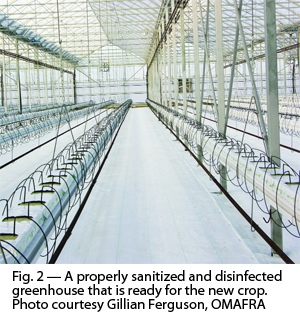

Be Mindful of Re-contamination – Growers need to maintain sanitation protocols to avoid re-contamination of the clean surfaces (Fig. 2). To facilitate this, the following controls are recommended:

Be Mindful of Re-contamination – Growers need to maintain sanitation protocols to avoid re-contamination of the clean surfaces (Fig. 2). To facilitate this, the following controls are recommended:

• Provision of disinfection boot trays or clean footwear dedicated to use in the greenhouse.

• Proper cleaning and disinfection of all heavy equipment, carts, crates, knives, etc., prior to their use in the greenhouse.

• Wearing of clean outer clothing by all entering the greenhouse.

• Disinfection of hands and wearing of gloves, etc.

This list of reminders provides the basics of a good sanitation protocol. Throughout this process, growers are also reminded to carefully read labels of all products used, and to follow all safety precautions recommended. n

Gillian Ferguson is the greenhouse vegetable IPM specialist with the Ontario Ministry of Agriculture, Food & Rural Affairs, in Harrow, Ontario. • 519-738-1258 or gillian.ferguson@ontario.ca

Print this page