Features

Containers

Inputs

Growing in the Green: Some winning combinations

The demand for quality combos continues to grow; what else can you do to boost sales and profitability?

December 9, 2014 By Melhem Sawaya

If you have to trim combos, adjust the timing.

If you have to trim combos, adjust the timing. Dec. 9, 2014 — As a bedding plant grower, you prefer to grow the items that are most profitable. Unfortunately, the demand for that item could be limited. We can only grow items that are in demand and work to make them as profitable as possible.

With the popularity of mixed containers, we need to produce excellent combinations at the most effective cost. The following is meant to give some guidelines to achieve those goals.

Every grower must have his or her own definition of a mixed container (combination). It is like a mission statement for your operation and sets the basic standards or principles for your combinations.

The definition that I would use is as follows: my combinations are a group of three to four cultivars (varieties) that would grow and look better and generate higher marginal profit in a combination than if sold alone.

PRODUCTION

Soil. Whether in combinations or any other crop, the potting media should be analyzed by an independent media testing lab-oratory, mainly to know if the pH is where you want it to be. My preference is to have a pH between 5.5 and 5.8, since 90 per cent of the main combination cultivars are petunias and calibrachoas.

This pH level is not the best for geraniums. However, in my view, geranium does not belong in any combination, because by July it will be dwarfed by other cultivars.

As for soil EC, it should be between 0.6 and 0.7 using the two water to one media test by volume.

Water. Water liners or 4” pots with fertilizer of 1.5 to 2.0 EC before planting.

Water the media before planting to avoid over-watering after to prevent plants from getting buried. Water lightly after planting until plants are well established.

Fertilizer. Use the fertilizer to adjust your pH to be 5.6 to 5.8 and your EC 1 with 2 water to 1 media test.

To change media into more:

- Acidic, use 18-9-18.

- Alkaline, 14-0-14.

- Neutral, 17-5-17.

Knowing your crops and what they prefer makes the difference between an OK crop and an excellent one. Only by doing soil-testing will you be able to catch fertility variances before they end up being a problem.

Light. Whether it is combination or a single variety in a pot, lighting is very important. It’s important to provide sufficient room all around the containers so that all the plants in the

container are exposed to light, especially when there are plants that trail down the sides. Containers can be started pot to pot, and then spaced to finish.

Temperature. All crops should be started warm (18-20 C), then finished cool; some crops can only go down to 5 to 6 C, while others shouldn’t go below 13 C. Pick combo cultivars that are temperature compatible. The worst scenario is to grow a cool-loving variety that trails warm, such as petunia. Some crops cannot take cool temperatures, such as ipomoea or annual and perennial hibiscus.

Pest control. In spring production, greenhouses are full and that makes pest control an interesting task. Many steps need to be taken:

- Start with clean plant material.

- Know the potential pests each crop attracts.

- If biologicals are used, treat preventively.

- If chemicals are used, monitor very closely and treat accordingly.

- Many times a crop has to be cleaned chemically before biologicals are introduced. Consequently, knowledge of your chemicals is important so that you use those that are compatible with the biologicals you are planning to use. In many cases, both chemicals and biological pest control are needed in a way that they can complement each other.

- Try to complete pest treatments before flowering or at least three weeks before shipping because flowers are generally more sensitive to chemicals than is foliage.

Liners. All varieties planted should have been rooted in the same media, in programmed liners or 4” pots. Be sure they are active and alive, not yellow; not doped with PGRs; not crowded; not just pinched; and have them finished in full light.

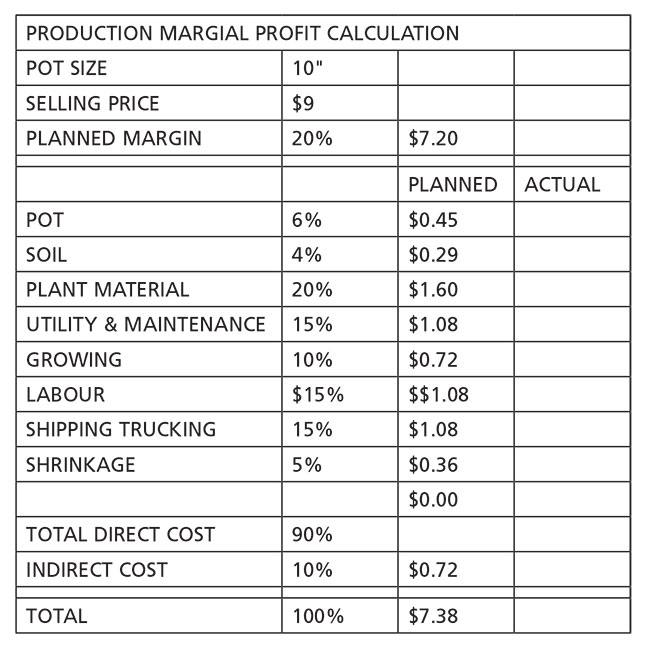

Costing: Profitable greenhouse operations know the cost of every product they produce…that is, if they sell it at a profitable margin! The costing process should be divided into four main categories – direct, indirect, shipping and shrinkage costs.

Direct cost. This cost is to include the following inputs:

- Pot or container costs to include all parts of the container, including the hanger and saucer.

- “Growing media per pot” means taking the cost of whatever media size you buy and actually filling the container you are trying to cost until the whole unit is used; you then divide the cost of the media unit, regardless of its size.

If you are mixing your own media, it is important to calculate the cost per cubic foot or cubic metre and know how many containers a cubic foot or cubic metre will fill. Many growers make the mistake of guessing on this calculation, because they figure it is a small cost per container. However, when you multiply it by the total number of containers grown, it is not a small cost.

It is very important when calculating cost per unit to calculate to four digits after the decimal. For example if your cost for 8” pots is $100/60 pots, the cost per pot to be included should be $0.1666.

- Product enhancement costs, including supporting rings, stakes, care tags, UPC labels or clips. And don’t forget the Grown in Canada sticker!

- ”Growing Area” should be calculated in square-foot/week. This is the space that each container is occupying in square feet for so many weeks. This could be three stages, that is: pot-to-pot at so many weeks, then half space for so many weeks, and then final spacing for so many weeks. All three stages are then included in the total.

- Crop maintenance.

Fertilizer used could be figured in different ways. If it is a mono crop, then it is easy – take the cost of the total fertilizer used and divide by the number of containers. If fertilizer is wasted on the ground, it is still a cost. If it is for multi-crops, take the total cost and factor the different fertilizing frequencies before you divide by the total number of pots for every crop.

Include water usage cost, even it is minimal.

Pest control, which is getting to be a bigger cost factor than it used to be, often ranges from one per cent to 10 per cent of the total cost. This should include insecticides, fungicides and biocontrols.

“Labour costs” include wages for watering, spraying, crop monitoring, pinching, spacing and every step that is involved to keep the crop in best form.

- Labour calculation of every step that it takes to do any of these jobs.

Calculate these in seconds, not minutes. When you multiply by the total transactions, fractions of a second make quite a

difference.

Indirect costs. These exist independent of the crop size. Some examples are mortgage payments or the owner’s salary.

Indirect cost calculations include the following: bank charges of the mortgage, operating loan, principle and interest; management fees; all wages that are not directly related to the production volume; and, of course, the various government fees.

Shipping costs. These used to be about three to five per cent 20 years ago, but have since risen to about 15 to 25 per cent due to a variety of factors. Reasons for this include: fuel costs that have doubled; wage increases; frequency of delivery (smaller orders more often deliveries); truck insurance; and depreciation.

Shrinkage costs. These should be factored in every crop costing for two main reasons: to have the right promised amount to your customer, and to project your actual costs.

The shrinkage cost could be due to poor crop quality; crop failure; the fact the crop was sold at much later date than targeted date which means extra costs; plants not sold; plants were sold but not paid for due to pay by scan; complaints (probably excuses because sales at the store are slow); and bad accounts, including customers who did not pay for a variety of reasons.

GUIDELINES FOR PROFITABLE MIXED CONTAINERS

Here is a checklist that’s in addition to the main procedures that were mentioned before.

Plant live, pest-free plants. It is much better to solve the problem at the beginning because inferior products at the start not only cost more, but will also involve extra treatment to the whole crop.

Use the minimum number of liners per container that will result in a good product at the shippable date.

Compatible varieties are very important not just for ease of production but also for economics. A very vigorous plant can take over the whole combination. On the other hand, a very compact variety will most probably disappear completely.

Fertilize continuously, but do not over-water and check EC and pH.

Use high calcium and potassium ECs to control height. This will make water less available to the plants.

Use different fertilizers to adjust minor soil pH: 18-9-18 to lower pH; 14-0-14 to raise pH; and 17-5-17 for neutral pH. Regardless of which fertilizer you are using, if the EC is too high, the pH will be low: balance and moderation is the key.

All crops should start warm and finish cool. All plants should have good root systems before they are cooled. At the same time, it is just as important to cool the crops at the end of the growing cycle, especially cold crops.

Maximum light is a must to grow strong plants that will be acclimatized for outdoor production. We cannot grow plants under rows of hanging baskets three deep and expect the plants to perform well when they get outdoors in full sun.

The number of cultivars in general is three per combination. More is not better and it is more difficult to find cultivars that look good and grow well together.

Seed varieties are just as good as vegetative varieties and sometimes they are better. You can use some of each.

Use the best cultivars (vegetative or seed) because at the end of the day, they are the cheapest. Select them according to your conditions and the outdoor environment of your market area.

Treat vigorous varieties with growth regulators before planting. It is the most economical way to do it, and better for the consumer because this will give a larger window between the treatment and selling date.

Expensive containers should only be used for upscale plantings to justify the cost of the container where the product is not meant to be transplanted. Many presentable containers that function very well are priced reasonably.

Space your planting dates. You do not sell all your containers in one week, so why would you plant all of them in the same week?

Sell fresh plantings, not old, for two reasons.

- Fresh plantings require less maintenance and shorter growing time, which translates into better marginal profit.

- Fresh plantings have better shelf life at the retail area and the ultimate consumer. Because the container media is not root-bound, the planting media will hold more water. As well, younger plants adjust to different climates more successfully than do root-bound containers.

Ten-inch baskets won’t work for combinations – the size is too small for successful products and the shelf life is too short. The smallest should be 12” containers.

Number of cuttings per pot: 10” (not a size for mixed container); 12” (4-5); 14” (4-5); 16” (5-7); and 20” (5-7). More cuttings than that per container affects quality and shelf life, and reduces profits.

Grow only what is ordered.

Selling price should clear a minimum of 20 per cent profit margin if any operation can survive. That is why it is much more important to calculate profit margin and not dollar sales.

PROFIT MARGIN CALCULATION

By calculating the costs before production begins, you’ll know the parameters of every cost aspect. This means no surprises at year-end. It also provides the guidelines to beat the projected costs where possible. These numbers are only a guideline; the true picture is when you plug in your actual costs.

As mentioned in the beginning of this article, planning is the key to success.

Understanding the kind of product you are trying to achieve and planning for every step ahead of time is a major key to achieving a profitable business.

PERCEIVED UNDERSTANDING OF MIXED CONTAINERS

“Leftover liners.” The days of thinking you can put together plants left over from other plantings are over; combinations are planned crops and not a last thought.

Sticking a couple of “trailers” the week of shipping. In the same scenario, if you received some late orders for combinations and are short on availability, for a fast fix you could put in a couple trailing plants. However, you will end up with some patched-up, inferior products that only increase the chances of losing these orders for the next season.

Magazine picture. Utilizing a picture from a magazine (including a breeder’s catalogue) and making it the basis for most of your production is rarely a good idea. Many times, your plants will never replicate the magazine image.

The problem is that plants do not always work well together for a long time. The combination looks great for a one-week window and then falls apart.

In other cases, cultivars clash and the more vigorous varieties take over. Soon you’ll have four- to six-variety combinations changed to two- to four-variety combinations…or less. Try the product in the photo on a small scale and see how it works for you and the consumer, and then expand on the program if it shows promise in performance and profits.

Relying on your favourite cultivar and adding anything that goes with it. Many combinations have to have a certain cultivar because it is one of your favourites and it usually works with any other cultivar. But customers have different tastes, and despite what we think, they may not like this combo. If you don’t listen to your customers, you’ll soon have bulkier recycling piles.

A cultivar surplus ends up with any other cultivars. Computers are great tools, but adding an extra zero to an order can happen at the planning stage. The temptation is to use the extra plants in a variety of combinations.

Remember that correcting mistakes at the earliest stage is the most cost effective remedy. The major goal in dealing with any surplus is to increase sales rather than hinder them. Only use the surplus if it enhances the product. You could also try to sell the surplus or part of it, or spread the surplus over different pot sizes. If none of these solutions meet the market demand, then it is much more cost effective to discard the extras at the propagation stage.

TYPES OF MIXED CONTAINERS

- Cultivars of the same genus, such as three petunias or three calibrachoas of different colours that have the same growing habit.

- Three to four genera per container, for example petunia, calibrachoa and verbena; or lobelia, pansy and bacopa. Just make sure you are selecting genera that grow under similar cultural conditions.

- Colour co-ordinated varieties that are becoming very popular because they are intended to match certain window shutters, doors/or patio furniture. Make sure the combination meets your standards.

- Leaf size and texture co-ordination, so that one variety doesn’t take over the whole container.

- A monochrome presentation of different cultivars to match lawn furniture, special occasions (such as weddings, etc.), or buildings (such as a restaurant or lobby, etc.).

Melhem Sawaya of Focus Greenhouse Management is a consultant and research co-ordinator to the horticultural industry. Comments on this or any other article are welcome at mel@focusgreenhousemanagement.com.

Print this page