Features

Growing Media

Inputs

How your soilless mix can improve water and nutrient retention

You may be surprised to learn how your production choices impact soilless mix performance in many different ways.

April 17, 2018 By Dr. Johann Buck

Unlike days of old, adding super absorbent polymers can vastly improve water retention. Photo credit: RainSoil

Unlike days of old, adding super absorbent polymers can vastly improve water retention. Photo credit: RainSoilWhile recently watching a television special on the great women of ancient Egypt, I was reminded that depictions of containerized plants, specifically non-native trees being transported in large containers, can be traced back millennia. By the fifth century, containerized plants were common, and some fast-growing herbaceous species were grown in containers for use in festivals.

These ancient gardeners likely faced many challenges, as the soil they used in the containers was likely mineral soil and inappropriate for container gardening. The use of field soil in container mixes, although inappropriate, was common until the mid-1950s with the development of the University of California (UC) mixes. The basic UC mix was 50 per cent sand and 50 per cent peat by volume.

However, the UC mixes failed to become widespread for two reasons. First, the proper grade of sand was difficult to obtain, and the success of the mixture was dependent upon using it. Second, the mixture of 50 per cent sand and 50 per cent peat by volume was heavy. By the 1960s, Drs. James Boodley and Raymond Sheldrake of Cornell University had developed an alternative to the UC mixes: the Cornell peat-lite mix.

The primary components of the Cornell peat-lite mix were German or Canadian sphagnum peat moss, perlite, vermiculite and some essential plant nutrients. These ingredients were light, consistent and readily available. Dr. Merle Jensen, Professor Emeritus of the University of Arizona and former graduate student of Dr. Sheldrake, remembers working on the Cornell peat-lite mixes: “The Cornell peat-lite mixes were developed primarily for vegetable and bedding transplants.”

Dr. Jensen would go on to develop early soilless media methods for producing vegetables using the Cornell peat-lite mix. Since the advent of the Cornell peat-lite mixes, both suppliers and growers have strived to improve upon those early soilless mixes. Improvements to both the ingredients and our understanding of what plants require when placed into a container have greatly improved over the years. So how can you leverage that knowledge to maximize nutrient and water retention with your soilless mixes?

Know the components of your soilless mix

First, start by understanding what’s in a mix. Soilless mixes (or growing media) are a composite of different components that serve four purposes: to provide physical support to the plant, exchange gas, serve as a water reservoir and exchange nutrients.

Soilless mixes are typically a blend of both organic and inorganic components. Organic components include peat, coir, bark, rice hulls and wood fibre. Inorganic components include perlite, vermiculite, pumice, sand and super absorbent polymers (SAPs).

There is no one soilless mix that works best in all situations. However, with a few simple guidelines, you can ensure you’re starting with a good mix that provides optimal air and water for the plant. It’s also important to be proactive throughout the production cycle to be sure you don’t unintentionally compromise the structural integrity of your mix.

Physical properties to look for

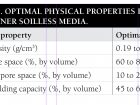

Optimal physical properties are an essential part of soilless mixes. This includes the proper distribution of air, water and solids. The structural components of a soilless mix, both organic and inorganic, comprise the solid portion of a soilless mix.

In between these solids are the pore spaces. The pore spaces created between the solids, depending on size, shape and orientation, will either hold water against the pull of gravity or they won’t.

We refer to the water remaining in the container after freely draining as water-holding capacity (WHC). However, not all water left behind is plant-available. Water that is held tightly against solids by adhesion and is unavailable to the plant is referred to as hygroscopic water.

Pores that don’t hold water serve a great purpose as well, since roots need oxygen for respiration. Generally, a good soilless mix will possess 10 to 20 per cent air-filled pore space (APS), 45 to 65 per cent WHC, and a total pore space of 65 to 85 per cent by volume.

Suppliers should be able to provide these specifications upon request. It’s important to ask what column height was used to determine the physical properties, because column height affects them. If you mix your own soil, consider using a reputable laboratory that can measure the physical properties of horticultural substrates.

Factors impacting physical properties

How can you impact the physical properties, and in turn, the performance of your soilless mix? You may be surprised to learn how your production choices affect it in many different ways.

Container height: Your choice of container height affects the soilless mix. As container height increases, there is more gravitational force on the water column inside the container, increasing drainage and reducing WHC.

Handling/mixing: Keep in mind that when it comes to soilless mixes, less handling is better, and excessive mixing can create problems from the start. Excessive mixing can damage the soilless media components and lead to reduced APS and drainage.

Compaction happens when pressure is applied to the soilless mix at planting, usually around the roots. Compaction usually leads to decreased APS and water infiltration, which can lead to uneven drying. It’s best to plant into a dibble hole and water in. When watering, it’s wise to use the appropriate water volume and distribute evenly. Otherwise, this can lead to channeling and uneven and excessive drying.

Water pressure is more of a concern when hand watering. Overly high water pressure and incorrect water breakers can lead to compaction and even plant damage. Using the correct water breakers and applying even water distribution are crucial. Proper training is important as well, and videos are available to show employees proper hand watering techniques.

Shrinkage is the loss in volume of soilless mixes, which can happen during mixing or after being placed into containers. This phenomenon, attributed to settling of fine particles into non-capillary pores, changes the physical properties of soilless mixes by decreasing the column height and the proportion of macro and micro pores. Microbial decomposition of the organic components during plant production also leads to shrinkage.

Rewettability and water retention

Organic materials such as peat tend to be hydrophobic and can be difficult to wet and rewet, especially when dry. Peat’s hydrophobicity is the reason why surfactants, aka wetting agents, are added as an ingredient. Surfactant is short for SURFace ACTive AgeNT.

Surfactants essentially make water wetter. What does that mean? It means they decrease the surface tension of water. When applied to soilless mixes or irrigation water, the result is a decrease in both the amount and duration of watering required to reach WHC.

Water surface tension can be measured in dynes per centimetre (dyn/cm). The surface tension of distilled water is 72 dyn/cm at 25 ºC (77 ºF). Depending on the chemistry and purpose of the surfactant, water’s surface tension can be reduced significantly. Surfactants applied to soilless media or via irrigation water should be non-ionic, pH-neutral and low-foaming.

Non-ionic surfactants are generally stable, do not have a charge (unlike anionic or cationic surfactants) and are generally safe for plants. They can become unsafe when the application rate exceeds the recommended dosage. It’s important to understand that surfactants do not increase a soilless mix’s potential WHC and should not be confused with other products such as super absorbent polymers (SAPs) that aid in water management.

Super absorbent polymers (SAPs)

SAPs, also known as hydrogels, are added to increase WHC. Most people have already encountered SAPs, especially if you’ve ever used a disposable diaper. SAPs are the primary absorbent component in disposable diapers. They are generally white in colour and vary in size, but not always.

Agricultural SAPs are typically polyacrylates, prepared from acrylic acids and a binding agent like potassium through solution or suspension polymerization. Polyacrylates are non-hazardous and biodegradable, with a degradation of about 10 to 15 per cent per year. SAPs can hold from 40 up to 500 times their weight in water and release up to 95 per cent of the water to the plants’ roots.

Amendments like SAPs and surfactants are just one of the ways to enhance your soilless mix’s water and nutrient retention. For proper plant production, soilless mixes require the proper balance of air, water and solids. A good soilless mix can quickly become compromised if not handled or watered correctly. Understanding how your production methods impact your mix can make a huge difference in how today’s products retain water and nutrients for your crops.

Dr. Johann Buck is a plant scientist, a Certified Crop Advisor (CCA) and director of sales and product development for RainSoil.

Print this page