The Van Nieuwenhuyzen family at Vanco Farms in Mt. Albion, Prince Edward Island, has a knack for innovation.

The Van Nieuwenhuyzen family at Vanco Farms in Mt. Albion, Prince Edward Island, has a knack for innovation.

The most recent example is a straw-fuel boiler to heat their constantly

expanding greenhouse tulip operation. The family hopes this latest

investment will decrease the high heating costs they have experienced

using oil the past few years.

But first some background.

Taking the knowledge of tulip-growing gained in their native Holland,

Peter Van Nieuwenhuyzen and sons Willem and Rit are looking at a

promising future as the only major commercial tulip grower in Atlantic

Canada.

After adding tulips to their 800-acre grain and 1,000-acre potato

operation in 2002, the Van Nieuwenhuyzens looked for ways to make the

new crop pay and earn its keep. They started with a few acres for the

bulb market. In 2004, they began growing fresh cut tulips in a

2,000-square-foot greenhouse.

|

|

| Vanco Farms is one of a very few cut tulip growers outside of Ontario and British Columbia. |

|

|

|

| The straw burner |

|

|

|

| Willem Van Nieuwenhuyzen of Vanco Farms. |

|

|

|

| Willem Van Nieuwenhuyzen of Vanco Farms. |

|

|

|

| Straw bales on the conveyor. |

VANCO’S BULB BUSINESS EXPANDED TO EIGHT ACRES

Encouraged by the bulb market, the family has increased production to

almost eight acres. That increase is essential to their fresh cut

flower business. “We use our own bulbs for the greenhouse tulips,” said

Willem.

The tulips are planted from September through November. They go into

coolers that initially are at 9º C and later lowered to 1º C. “Every

week during the winter we take out one set (1,000 tulips) and put them

into the greenhouse. Four weeks, later they are picked,” said Willem.

Harvesting begins in January and continues through to Mother’s Day.

Willem pointed out that sales begin to spike in March when signs of

spring are evident.

Ten employees are involved with the crop. Picking is carried out twice

a day, seven days a week. “The idea is to pick them just before they

bloom, so they are that much fresher for the buyers. They bloom after

they are taken home and put in a vase.”

The seven or more varieties of Van Nieuwenhuyzen tulips are distributed in shops throughout the Maritimes region.

Peter Cantley, vice-president of Floral and Gardens with Loblaws

Companies Ltd., noted that Vanco Farms tulips are doing well in the

market. “There are a variety of colours to choose from,” said Cantley,

“and we are happy to share that the sales of the tulips have been very

successful in Prince Edward Island and around the Maritimes.”

He pointed out that the tulips are an outstanding and long lasting

product and Loblaws are proud to support an Island producer. The local

Superstores report that at least a dozen bunches of 10 are sold daily

in the Island stores alone.

TAPPING AN EXPANDING MARKET SOUTH OF THE BORDER

Equally impressive is a growing wholesale market in Boston. “Rit does

the marketing and sales and we have a strong market in Boston,” pointed

out Willem. The farm deals with five wholesalers and they in turn

market the Island-grown tulips to florists and other retailers, with

the bulk heading to wholesalers in Boston.

Now in their third season marketing into the U.S., Willem noted that

demand has grown and consumers in Boston seek out the fresh cut Vanco

tulips.

The farm has two refrigerated vans, and the vehicle that delivers to

New Brunswick goes on to Boston. Initially shipping once a week, the

farm just recently began shipping twice a week to Boston and the other

two Maritime provinces. About 15,000 tulips are shipped each week.

These are all signs the tulip operation that had a slow start is indeed

a blooming success.

But no successful farming operation can rest on its laurels. The family has recently turned its attention to cost-cutting.

During a visit to the Netherlands in 2008, Willem saw a straw burner

being demonstrated and was quite impressed. “We were going through a

tank of oil every two days, and with the high cost, we had to look at

something else.”

With 10,000 square feet of space and plans to triple in size over the

next three years, something had to be done to make heating more

affordable.

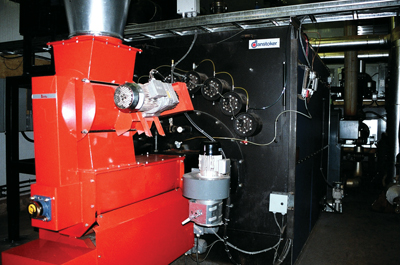

That’s where the Linka straw burner from Denmark comes in.

This $300,000, one thousand kilowatt system that takes up a whole room

in the warehouse, carries 4’x8’x3’-foot bales of straw on a track to a

shredder. Here it is separated and sucked into a vacuum pipe that moves

the finer straw into the boiler.

It easily heats the 10,000-square-foot greenhouse to 18ºC. It takes

about 100 to 300 acres of straw per year to fuel the burner. “It could

pay for itself in four years, depending on how the price of oil

fluctuates,” said Willem.

He “guestimates” that the straw costs will be about $20,000 to $30,000

a year. Based on using 100,000 litres of oil a year at 70 cents a litre

or more (at the time of my visit earlier this year), the savings would

be considerable.

The first of its kind in North America, the straw burner operates much

like a home heating furnace. Hot water is pumped into the in-floor

heating systems in the warehouse, Willem’s own home, as well as the

greenhouse.

From field to fuel, straw is the latest alternative energy source option for small growers.

Kathy Birt is a freelance writer and photographer in Prince Edward Island.

Print this page