Features

Crop Culture

Inputs

Growing Points: Diagnosing crop problems

February 7, 2012 By Dr. Mohyuddin Mirza

Knowledge and its timely use is the key to sustainability and profitability; time-sensitive crops, such as poinsettia, demand close attention

Knowledge and its timely use is the key to sustainability and

profitability; time-sensitive crops, such as poinsettia, demand close

attention

|

|

| The roots were poor compared to the top growth. Advertisement

|

Poinsettia markets have significantly changed in Alberta during the past

decade. Reduced production levels are due to economic reasons. Growers

switched to supply more plants to specialized markets than to commercial

wholesalers. This shift necessitated a greater focus on growing

top-quality plants with good shelf life.

Many small-size growers, something in the area of 10,000 square feet, maintained their market share by shifting to growing higher quality material. However, not all of them invested in better environmental controls.

Poinsettia is a very time-sensitive crop. The plants now have to be ready for shipping by the end of November, rather than the usual shipping date in the middle of December. You cannot afford to let problems develop; otherwise, the entire crop can be unsalable.

Here I share with you the actual story of a small-size greenhouse. We were able to turn the crop around, but for many days we were not sure if it would make it.

LEAF EDGE CHLOROSIS NOTED IN EARLY OCTOBER

It all started the first week of October when a poinsettia grower asked me to have a look at his crop. The way he described the problem with leaf edge chlorosis, the problem appeared simple enough – perhaps magnesium deficiency. The grower had already sprayed the plants with a solution of

magnesium sulphate but the plants were not responding.

Lower leaves showed symptoms of chlorosis, spreading from the edges and then inward. Veins were distinctly green and the inter-veinal area was yellow.

Not all plants showed these symptoms, especially in one part of the greenhouse. Some varieties had pale-coloured leaves and an overall lack of vigour. Some lower leaves were showing “necrosis” on their edges.

The grower had a good pH and E.C. meter, but regular readings were not taken and recorded. Leachate was collected from several plants and pH and EC readings were taken. The pH ranged from 4.8 to 5.5 and EC ranged from 0.8 to 1.5 millimhos. The temperature set points were 18°C night and venting at 23°C.

|

|

| Lower leaves showed symptoms of chlorosis, spreading from the edges and then inward.

|

ENVIRONMENTAL SENSORS WERE NOT BEING USED

There was no system to record actual temperatures. Similarly, relative humidity was not measured or recorded and the grower was just going by the dripping he observed on the concrete floor. Heat was mainly provided by infrared heaters and some forced-air furnaces.

The roots were poor compared to the top growth of the plant and there was also some evidence of root rot. Good fertilizer records were kept. There was only a one-head injector available and no calcium feed since the beginning of the crop in late July.

It was obvious that pH was the first issue that needed to be corrected. It is not possible to adjust pH with just one application of a product like potassium bicarbonate. It takes at least two weeks before pH can be turned around.

REGULAR MONITORING OF pH MUST BEGIN EARLY

Growers have learned about the pH of growing media, water, fertilizer solutions and chemicals. However, when it comes to managing crops, it is not understood that pH correction takes more time than simply adjusting E.C. I always emphasize that regular monitoring of pH is very important, and to do it right from the beginning of the crop. It must be graphed and checked regularly.

You may be doing everything else right, but if the pH is not in the proper range, issues can develop easily. The poinsettia leaf (on right side) is a good example where iron toxicity is strongly suspected. Growers should have a good understanding of pH in the growing medium and how it affects the uptake of nutrients. Of all the trace elements, iron is the one that is taken up in relatively larger amounts at pH below 5.5 and can cause toxicity. Basically, remember that uptake of all trace elements is higher at pH below 5.5, except molybdenum, which is low at higher pH.

KEEP ‘REMEDIES’ IN STOCK; DELAYS CAN BE COSTLY

In this case it was decided to apply potassium bicarbonate to bring pH above 6.0 and no fertilizer would be used until this happened. The grower did not have potassium bicarbonate handy; it had to be brought in and took five days. Those five days were very important for a time-sensitive crop like poinsettia. How much to apply and how to handle it through the injector system were other questions.

A soil test revealed the following … and remember it took a week to get the results back.

|

Nitrogen and phosphorus were in the deficiency range. Calcium, potassium and magnesium were in the sufficiency range. Iron levels were excessive, while boron was in the deficiency range. Tissue analysis revealed a deficiency of nitrogen, calcium, sulphur and boron. The fertilizer program was adjusted to reflect these deficiencies and toxicities, and foliar feeding of calcium and boron was also introduced. A few other important things were also discovered during this diagnostic process.

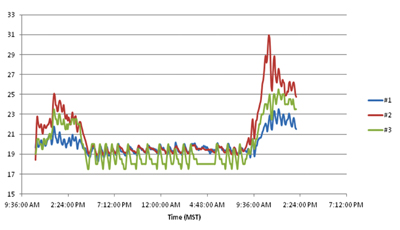

- Temperature control system was a “primitive” system. There is a single thermostat with one setting of 18°C. It meant that once the temperature fell to that setting, the heat was turned on. There was no coordination between heating and venting and there was no means to actually measure the high and lows.

|

|

| It took a lot of work to turn the crop around successfully.

|

A friend of the grower placed three sensors in the greenhouse and recorded actual temperatures. The drop in temperature from night to day was very rapid and that can explain some edge burning. The spike in day temperatures could be the result of vents not reacting to temperature changes; the grower also thought it might be a problem of sunlight directly hitting the sensors. The point is that a better temperature control system is needed, and the grower has promised to implement one.

- pH and E.C. must be monitored on a regular basis, right from the beginning. I was happy to see this was being done after I had received the graphs.

Just look at the information available to help make decisions quickly enough to turn the crop around in time. The grower has promised to do it now regularly, but he still wonders why did he have good crops for so many years without all this?

- Products like potassium bicarbonate should always be in stock. Waiting five days, as we did in this case, was too long.

- A two-head injector is a good investment, so that all elements can be supplied together.

- Watch for elements like sulphur. In this case, it was deficient and symptoms can look pretty close to that of nitrogen deficiency. Taking tests regularly is a good idea.

The crop did turn around, but signs of the journey to recovery were still visible; with extra labour, many lower leaves had to be removed. Knowledge and its timely use is the key to sustainability and profitability.

Dr. Mohyuddin Mirza is a retired Alberta Agriculture, Food and Rural Affairs researcher and extension specialist.

• drmirzaconsultants@gmail.com

Print this page