Features

Crop Protection

Inputs

GREENHOUSE GROWER NOTES September 2006 2

January 28, 2008 By Shalin Khosla

An overview of Ontario’s greenhouse vegetable industry. Among continuing trends, glass and hot water heating are popular with new construction.

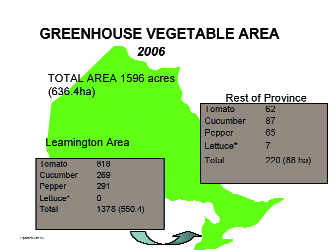

The greenhouse industry in Ontario is now at 636 ha (1,596 acres), up from 576.9 ha (1,442 acres) last year. Most of the new construction occurred in southwestern Ontario (Essex and Chatham-Kent counties). Sixteen per cent of the new construction was outside this area.

The greenhouse industry in Ontario is now at 636 ha (1,596 acres), up from 576.9 ha (1,442 acres) last year. Most of the new construction occurred in southwestern Ontario (Essex and Chatham-Kent counties). Sixteen per cent of the new construction was outside this area.

The trend towards glass continues as 59 per cent of the new construction was of this material. Eighty-four per cent of the new construction used hot water heating, allowing the grower to easily obtain the ideal greenhouse climate and use flue gas carbon dioxide in conjunction with hot water storage tanks.

The cost of energy is 30 to 40 per cent of the cost of production, or may be higher depending on the price of natural gas contracted. The increase in fuel costs has had an impact on the industry as more growers are looking at alternative sources of fuels and conservation techniques. In the past two years, there has been an increase in the interest of using biomass as a fuel to heat the greenhouse.

This, in conjunction with types of fuels, fuel handling, and combustion and boiler systems, has resulted in various combinations that are successful for the individual greenhouse operation. The key source of fuel has been wood and wood waste products (mainly as wood chips or sawdust). Growers are looking at various combinations of biomass to maximize energy obtained and minimize cost. It is critical that the supply, quality and price of the biofuel are stable. The equipment (fuel handling and combustion chamber) must be able to handle the supplied product efficiently with minimal maintenance and breakdown costs.

The need to maintain the ideal greenhouse environment has resulted in new greenhouse construction using 5.5 m (18 ft) as the standard gutter height, with some new greenhouses constructed at a 6 m (20 ft) gutter height. The increase in gutter height results in a more uniform temperature profile within the plant canopy and assists in maintaining an environment that minimizes the incidences of diseases and maintains a uniform production throughout the season.

Greenhouse operations with the new glass structures have energy curtains installed that help lower the night energy requirements and assist in moderating the internal greenhouse environment when used during periods of high light intensity, especially in the transition season of spring. Previously, growers with double polyethylene-covered greenhouses used shade materials applied to the outer surface to alter the greenhouse environment in the summer. Over the past two seasons, growers have used a new product that reduces IR radiation. This product allows PAR light transmission, but reduces IR transmission, resulting in a cooler greenhouse environment and lower leaf and fruit temperature.

The desire to obtain the highest quality, high yielding, low crop maintenance cultivar has resulted in growers evaluating numerous lines, trying new cultivars on a small scale, and adopting them. The beefsteak tomato cultivars currently grown are ‘Macarana,’ ‘Big-Dina’ and ‘Gro-Dina.’ The cultivar ‘Clarance’ is still used as a standard for Tomato-on-the-Vine type, with ‘Grandela,’ ‘Fresbie,’ ‘Tricia’ and ‘Brilliance’ as some of the newer lines. There are numerous specialty tomatoes grown and are marketed exclusively under brand names.

The cucumber cultivars range depending on the time of the season and the growers’ production plan. Cultivars range from ‘Camaro,’ ‘Logica,’ ‘Talbot,’ ‘Mystica,’ ‘Curtis,’ ‘Gardon’ and ‘Kasha’ as the main cultivars with newer numbered lines tried on a small scale. The mini-cucumber industry remains steady, as any major increase in planting area reduces returns. The market continues to develop gradually.

There was a large change in the selection of the red pepper cultivar as most growers switched to ‘Facinato’’ and Red Glory’ as the main cultivars with some ‘Zambonie,’ ‘4-ever’ and ‘Triple 4’ plantings. ‘Stricker’ dominates the yellow cultivars, with some new lines showing promise. The orange standby, ‘Sympathie,’ continues to perform well, while newer lines such as ‘Orangery’ are grown on a larger scale.

The most popular growing media continues to be rockwool, but there are more growers using coco fibre, especially pepper and cucumber producers. There is increased interest in recycling nutrient solution as 96.6 per cent of the newer construction installed raised trough systems with the capacity to capture and reuse all excess nutrient solution applied to the crop. Some older greenhouse operations have retrofitted their production facility to capture and reuse excess applied nutrient solution. The debate continues as to which is the best system to use to disinfect the nutrient solution as all present systems control/minimize pathogens in the treated water.

The Ontario greenhouse vegetable operator continues to face the modern day challenges of farming by creating, adapting and adopting new ideas and technologies.

Shalin Khosla is the greenhouse vegetable specialist with the Ontario Ministry of Agriculture, Food and Rural Affairs in Harrow. • 519-738-2251, ext 405 or shalin.khosla@omafra.gov.on.ca

Print this page