Features

Energy

Management

Special Series European trends #2: Assessing CHP feasibility

May 21, 2010 By Paul Hovius

In the previous article (April 2010, pg. 12), the principles of a CHP

(combined heat and power) system for the horticulture industry were

described. In this article, we’ll elaborate further on the feasibility

of such systems. Please note: the figures used are based on conditions

in the Netherlands and should be adapted for the conditions in Canada.

In the previous article (April 2010, pg. 12), the principles of a CHP (combined heat and power) system for the horticulture industry were described. In this article, we’ll elaborate further on the feasibility of such systems. Please note: the figures used are based on conditions in the Netherlands and should be adapted for the conditions in Canada.

|

|

| The CHP units in the horticulture sector in the Netherlands are heat-demand driven. Advertisement

|

The CHP units in the horticulture sector in the Netherlands are heat-demand driven. This means that electricity production will take place only if heat or CO2 for the greenhouse is required. The cost of producing electricity with a gas-fired, reciprocating combustion engine is higher than with fossil fuel-fired power stations. The regular electricity prices are too low to compensate for the production cost. CHP systems save growers money since CHP heating costs are less than with an individual boiler. Growers must determine what size CHP system is optimal for their greenhouse, taking into account the CO2 fertilizing requirements.

DETERMINATION OF THE HEAT DEMAND

In principle, a CHP system will be in operation at full load. Part-load operation is only possible in the 100 to 70 per cent range, while the maintenance cost increases slightly with generated electricity and heat. During the time of greatest expansion of horticulture CHP systems in the Netherlands, some consultants calculated their feasibility based on 4,000 full-load hours per year without observing the heat demand. This is the quick (and dirty) feasibility calculation.

|

|

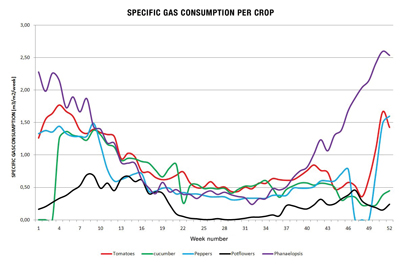

| Heat demand is expressed in gas input of the boiler in cubic metres per square foot per week. |

This example is for a five-hectare tomato operation.

|

LAT has another approach, which is focused on the heat demand of the grower. In the graph on page 33, the heat demand expressed in gas input of the boiler in m3/m2/week for different crops is shown. This gas consumption is representative for greenhouse growers in the Netherlands, but could be adapted for Canadian growers.

There are significant differences for the various crops. Potted flower growers have less heat demand in the summer, while phalaenopsis growers have a higher heat demand, in particular, in the winter. Of course, there are also differences between farms growing the same crop. In the summer, for example, some growers use some liquid CO2 instead of boiler/CHP gas, which results in less gas consumption. LAT incorporates the historical gas consumption of the grower in its feasibility calculation.

FEASIBILITY CALCULATIONS

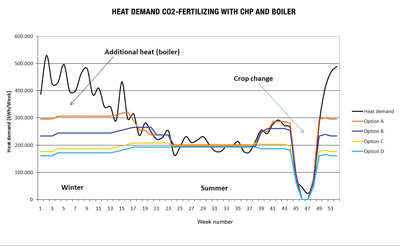

Based on the gas consumption of the grower, and the size of the greenhouse, the weekly heat demand of the operation expressed in kWh/week can be calculated. Due to low electricity prices at night and on the weekend, the CHP system is only in operation during the peak hours.

In the graph on page 33, an example is given for five hectares of tomatoes. The black line is the heat demand while the coloured lines are different options in CHP size. In this example, the power rating of Option A is 3 MW and Option D is 1,650 kW, while the other two options are between them. Option D runs 16 hours on working days, but a large amount of heat has to be supplied through an additional source, which is usually the gas-fired boiler.

Option A has about twice the rating of Option D and generates more heat during the winter period, but will operate fewer hours during the summer. In this example, the operation is limited to nine hours per working day. If the CHP power rating is increased, the hours of operation decrease, and this will affect CO2 fertilizing. Most growers prefer CO2 fertilizing in summer for about eight to 10 hours per day. In this example, the CHP operates 3,125 hours for Option A and 3,880 hours for Option D.

FEASIBILITY RESULTS

The aim of CHP is to reduce energy costs. The high investment in CHP should be paid backed through electricity sales. In the feasibility calculation, the following main items are taken into account: investment, maintenance cost and energy prices.

The investment costs are mainly the CHP, grid connection and gas supply. For each project, the circumstances are different, so the feasibility calculations are custom-made. The absolute monetary savings are important, but the savings in our example are not representative for the Canadian market. With a relative saving for Option D at 100 per cent, the saving for Option A amounts to 150 per cent.

We like to emphasize that it is also important to take into account the payback time for the different options. ■

Print this page