Features

Efficiency

Energy

FEATURE STORY – GREENHOUSE ENERGY AUDITS

June 12, 2012 By Treena Hein

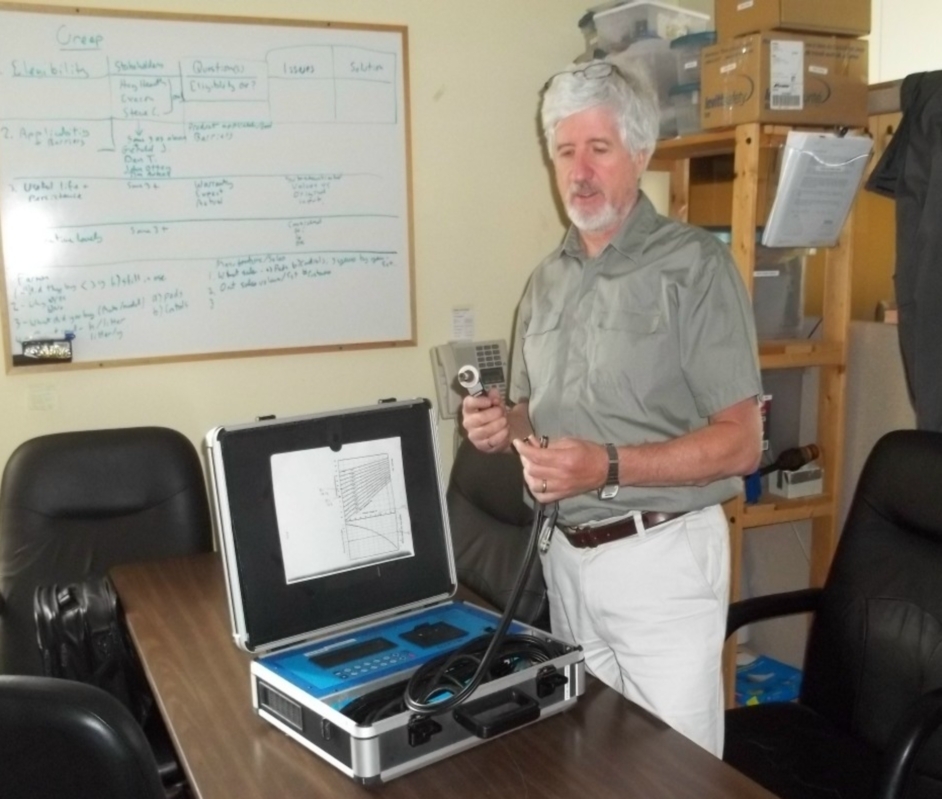

Ron MacDonald of Agviro, Inc. sets up a flue gas analyzer to check the combustion efficiency of a boiler.

Ron MacDonald of Agviro, Inc. sets up a flue gas analyzer to check the combustion efficiency of a boiler. Why you should proceed with an audit, what it should include – and what to look for in an auditor

In these times of extreme energy management challenges, an energy audit of your operation makes sense – especially when half the cost is funded.

“Almost all energy utilities in all provinces offer incentives for having energy audits completed, and the auditor you choose to go with should look after all the applications for this,” says Ron MacDonald, the owner of Agviro Inc. in Guelph, Ontario.

“There is also funding available for energy efficiency projects that stem from the audit.”

Agviro provides services relating to indoor air quality, mechanical design and energy efficiency, and has conducted about 40 greenhouse energy audits over the past year.MacDonald is a registered professional agricultural engineer who previously worked with Ontario Hydro to provide engineering services and more to agricultural clients.

However, many Canadian greenhouse operators have thus far been reluctant to proceed with an energy audit.

“It’s a case of ‘sticker shock,’ with the seemingly high cost of an audit still being a major barrier,” says Aluel Go, a farm energy auditor and visiting specialist at the Department of Biosystems and Agricultural Engineering at Michigan State University.

Go is currently spearheading a study with graduate student Trevor McLean that looks at the savings that can be reaped from greenhouse energy audits. The finished report, in Go’s view, is going to be crucial in convincing industry members that spending money on an audit is a very wise move. “Although the report is not finalized, it seems clear that audits are worth the money many times over,” he says.

“We’ve found that even large greenhouse operators, who can potentially attain an annual savings of about $100,000 from the results of an audit, are hesitant to ‘bite’ due to the audit cost as well as the lack of information on potential savings,” Go notes.

He says that’s where this report, which will include results from 25 recent audits, will fill a gap. Out of the 15 audits analyzed so far, eight are typical small operations that could each be saving an average of $15,000 to $20,000 (US) annually with the recommended energy efficiency improvements.

Putting aside cost and lack of perceived benefit, Go notes still other reasons why industry members haven’t been interested in audits.

“Greenhouse operators hear stories about others who have been ‘burnt’ by past commercial energy audit attempts,” he explains. “In addition, the lack of certified farm energy auditors is another limitation in our state. That’s one reason our department has developed our certified farm energy audit program, based on the ANSI/ASABE (the American National Standards Institute and the American Society of Agricultural and Biological Engineers) S612 farm energy audit standards that have been adopted by the U.S. Department of Agriculture (USDA).”

Michigan State University Extension trains and provides technical support to certified farm energy auditors, in addition to subsidizing farm energy audit costs in partnership with the Michigan Energy Office, Michigan Agricultural Energy Council, USDA-REAP (Rural Energy for America Program) and utility companies.

The state of Minnesota also funds a ‘Farm Energy Auditor Training Program,’ which graduated 13 farm energy auditors in March 2012. The training was coordinated by ‘The Minnesota Project’ (a non-profit sustainability group).

The Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA) does not currently offer energy auditor training as there has not been enough interest. Steve Clarke, OMAFRA’s energy and crop engineering specialist based in Kemptville, says he could set up training if 10 or 15 companies expressed interest.

MOVING FORWARD WITH AN AUDIT

As with any service you purchase in the hopes of improving your business, your choice of service provider – in this case, an auditor – is key. Besides ensuring that the auditor has experience and knowledge relating to greenhouse energy management and provides client references, Ron MacDonald says there are many more things greenhouse operators should look for before signing a contract.

“Auditors should be able to meter and measure both electrical and heating systems (EFIN, 4w3p, etc.), as well as having the capability of using modelling software,” he notes. “They should also be able to provide comprehensive reporting to Level II ASHRAE (American Society of Heating, Refrigeration and Air Conditioning Engineers).”

In addition, MacDonald believes greenhouse owners should never choose auditors who are selling anything. “You need an independent audit with no hidden agendas,” he says, adding, “Also always look for a comprehensive team approach, with mechanical, electrical and structural elements.”

In terms of what the greenhouse energy audit itself should include, MacDonald explains that there are two levels, but Level 2 is definitely preferable.

“A Level 1 audit is lower intensity audit that costs about $8,000 depending on your operation size, but the intensive Level 2 audit is what you want,” he asserts. “It will typically cost at least $12,000, and will be a thorough analysis of all aspects.”

Auditors should use newly available instruments such as infrared thermographers and hot water pipe flow meters, relative humidity meters, and flue gas data exhaust monitors.

MacDonald says every audit should involve a collection and analysis of historical energy use, a study of the building and its operational characteristics, and identification of potential modifications that will reduce energy use and/or cost. Every audit should also include an engineering and economic analysis of potential modifications, a rank-ordered list of appropriate modifications, preliminary budget costs and a report that documents the analysis process and results.

A followup visit by the auditor is highly recommended, in MacDonald’s view. “It’s not standard procedure, but it needs to be,” he says.

When a report this size is handed over from the auditor to the greenhouse owner, MacDonald says the sheer amount of information as well as technical terminology can result in the report often being largely ignored. “It’s too daunting, and nothing comes of it,” he says.

“The ideal situation is that the report is submitted and the greenhouse owner has a week or so to read over it, and then the auditor should sit down and go over it so that the customer can ask questions. You need this review meeting to get over the hurdle of understanding anything confusing, and it also allows the two of you to decide on a first project.”

Enertec Mechanical of Beamsville, Ontario, always holds followup meetings.

(Handing over the audit report is a starting point, says John Lelie, of Enertec Mechanical.)

“Handing over the audit report is a starting point, and we make sure to meet with customers shortly after that point,” says Enertec president John Lelie. “The followup meeting is an opportunity to answer questions and go over what to do next.”

He notes that the recommendations made in the report are prioritized based on rate of return, but sometimes the capital costs involved are high, and the grower is forced into lower rate of return/lower capital cost projects based on what they are able to invest at a particular point in time.

Aluel Go agrees. “The auditor needs to identify recommendations that align with the operational and strategic procedures and goals of management,” he says. “Otherwise, it won’t be implemented, despite the tremendous savings projected by that recommendation.”

Go thinks the auditor should also always be aware of operational and environmental variations among greenhouse operations, which may lead to standard ‘no brainer’ recommendations that may not be best for that operation.

Treena Hein is the Energy Edge editor.

Audit resources

BC Hydro audit incentives and efficiency project incentives

Ontario Power Authority audit and programs

Enbridge Gas (Ontario) audit incentives

Fortis BC (natural gas) audits and efficiency project incentives

The Canada-Ontario Farm Stewardship Program (COFSP) – Best Management Practices that may be eligible for funding are:

Category 25 – Farm Energy Audits.

Category 26 – Energy Conservation Measures for Agricultural Purposes.

Category 27 – Renewable Energy Production for Agricultural Purposes.

Enhanced funding can come from other organizations, like The Friends of the Greenbelt Foundation

See also Green belt Toronto-area enhanced funding from different sources

Check out Ag Energy Co-operative and FireFly Energy’s analysis software, ‘Enercompare.’ Once your operation’s energy, area and volume data are entered, ‘Enercompare’ will provide you with many different methods to compare and evaluate your energy use. A variety of graphs can be viewed and printed. A six-month free trial is available for new users, at which point an annual fee will apply. Ron MacDonald, who created the software several years ago, says there have been no major changes to greenhouse operations since the program’s creation, so it’s still up to date.

Michigan State University Extension Floriculture Team’s greenhouse energy audit resources greenhouse energy audit resources

As part of its Farm Energy Efficiency Program, the nonprofit agency ‘The Minnesota Project’ has created an extensive online resource centre. Greenhouse operators should scroll down and click on Technical Resources and Evaluation Tools and then Sample Audits and Case Studies. They recently created a video that outlines what is involved in an energy audit.a video that outlines what is involved in an energy audit.

OMAFRA’s Energy Conservation and Generation site

Partial List of Consulting Engineers in Ontario for Agricultural Energy Audits & Resources (updated in late 2009)

Print this page