Features

Efficiency

Energy

Energy-wise ‘sky farm’ greenhouse construction underway in Europe

August 21, 2012 By Treena Hein

Plantagon is building its first 'sky farm' in Sweden.

Plantagon is building its first 'sky farm' in Sweden. Featuring an urban vegetable greenhouse design that integrates solutions for energy, excess heat and CO2 from industry, waste and water, the first ‘Plantagon’ greenhouse is under construction in the city of Linkoping, Sweden. The building of the vertical farm began in February 2012 and the first crop is expected in 2013.

“I am immensely proud that Linkoping is the chosen site for the first [Plantagon] vertical greenhouse,” said Paul Lindvall, Mayor of Linkoping, in a Plantagon press release from February. “We will be the first city in the world to test the new technology and the systems involved to develop sustainable agricultural solutions for future cities.”

(This image shows the ground-breaking at the site in Linkoping in early February 2012.)

The Plantagon greenhouse is developed together with Sweco. “With this greenhouse we’re developing and fine-tuning the technical systems required for vertical farming in urban areas, together with several well-known Swedish partner companies,” says Hans Hassle, Plantagon CEO. “We want to gather expertise in the field, and our long-term objective is to create an international Center of Excellence for Urban Agriculture here in Linkoping.”

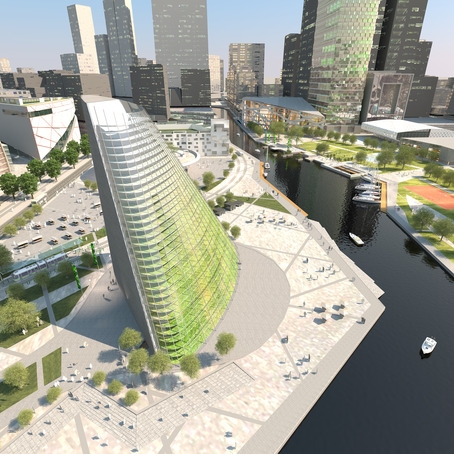

This is the design of the greenhouse building for Linkoping:

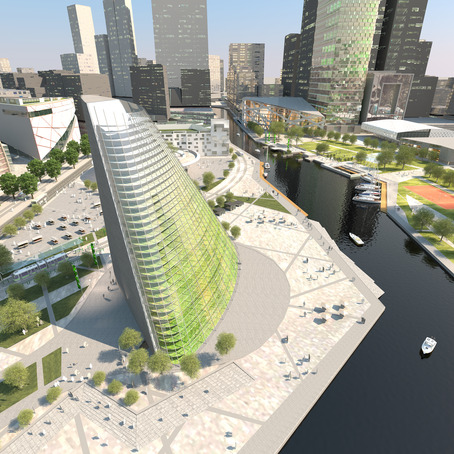

Here is another Plantagon greenhouse design:

Nuts and bolts of greenhouse operation

The Plantagon website describes how plants are grown as follows:

“The trays are equipped with a light-sealed nutrient solution reservoir, and the pots are irrigated about three times per day using an ebb-and-flow technique. A capillary mat at the bottom of each tray protects the individual plants from drought. Excess nutrient solution is collected and reused after disinfection.

The different system designs basically all have the same production flow and location of equipment. The machinery is located in the basement on one or two floors and the trays are transported to the top of the helix by a special tray elevator. The crops grow during the slow transport down the helix and are ready for harvesting when they reach the end of the helix at the basement level.

Food is harvested in batches using an automatic harvesting machine. After harvest, the trays and pots are disinfected, and the pots are separated and replanted with another seed for the next round in the cultivation loop. After germination, the pots are recombined with the trays and elevated to the top of the growing helix to repeat the process.

Read more about the Linkoping greenhouse here.

In a new article from Australia, it is stated that Stuttgart, Germany, and Barcelona, Spain are understood to have signed expressions of interests in building Plantagon “sky farms.”

Print this page