Features

Doubling the power of the sun

Updates on technologies integrating solar panels into greenhouse glass

October 17, 2022 By Treena Hein

Toronto-based Mitrex says its BIPV solar technology is entirely customizable to achieve the look of any surface material, transparency, pattern, or texture.

Toronto-based Mitrex says its BIPV solar technology is entirely customizable to achieve the look of any surface material, transparency, pattern, or texture. Greenhouses have long used solar power, to both grow plants and also warm up the greenhouse space in chillier temperatures. Now, solar energy capture technology has come to the point where greenhouses can also use solar power to generate electricity.

This technology is coming none too soon, at least in Ontario.

As reported in early 2022 by TNT Power (an Ontario power generation, distribution and automation company) “the Leamington-Kingsville area is experiencing unprecedented growth due to the expansion of the greenhouse industry. In fact, the area is expected to quadruple in electricity demand over the next 15 years, resulting in a critical shortage of electricity supply while infrastructure upgrades are still years away from completion at best.”

Toronto-based Mitrex is one company, offering what it describes as aesthetically pleasing and can be integrated onto every available surface, allowing clean energy to be generated on a mass scale: facades, glass, roof, siding. “The BIPV solar technology is entirely customizable to achieve the look of any surface material, transparency, pattern, or texture, and a patented coating process maximizes energy generation and ensures the panels last for decades.”

In greenhouses, Mitrex transparent Solar Glass is available for clear structures, and for opaque growing facilities, Mitrex offers opaque and semi-opaque solar technology that maximizes energy generation on otherwise unused surfaces. Owners can choose which solar technology best suits their needs to generate energy and profit.

Mitrex photovoltaic (PV) glass uses high-output monocrystalline silicon or thin-film technology. The glass consists of two layers of heat-tempered, laminated, low-iron glass surrounding integrated solar cells. The company states that its high-performing materials coupled with a 25-year product and performance warranty guarantee durable, long-lasting solar glass.

“The appetite for this product is growing steadily, and it is a market that we foresee will continue to expand as demand for local and high-tech farming solutions grows,” says Mitrex marketing manager Haris Mohsin. Mitrex has multiple greenhouse projects in various development stages across Canada and the U.S.

In terms the cost of the clear product, Mohsin says it’s very similar to traditional glass. “Batteries can be easily included into the system design but are not required for every greenhouse, as energy can be sent back to the grid at a cost or for energy credits,” he explains.

ROI is typically five to seven years.

Bifacial PV cells

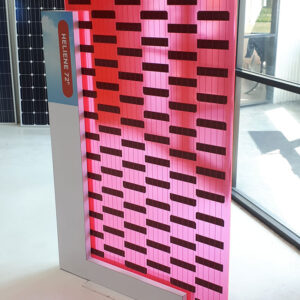

Heliene, based in Sault Ste. Marie, Ont., is another company offering greenhouse glass solar energy generation.

In 2019, Greenhouse Canada reported on its project with Niagara College and Freeman Herbs. A half-acre of southern-facing panes of rooftop glass (about five per cent of available surface area) in one of Freeman’s greenhouses was replaced with 600 of Heliene’s solar PV modules, containing light-polarizing polyurethane backsheets and ‘bifacial’ photovoltaic (PV) cells, explains Patrick Gossage, Heliene product innovation and business development manager.

The bifacial PV cells convert both sunlight from above, and some types of UV light reflected by the pink backsheets just below, into electricity.

“The backsheet filters out green and yellow wavelengths while enhancing red and blue wavelengths, which have positive effects on plant growth,” says Gossage. “This means the panels absorb less photosynthetically-efficient wavelengths and emit more of those with higher photosynthetic efficiency. Red wavelengths are re-emitted in random directions independent of the incidence light. The resulting red light is more diffuse and permits off axis capture from thin solar cells placed within the two thin glass layers that make up the panel.”

The glass itself diffuses incoming light, regardless of the angle of the sun. This minimizes the shading effect of the cells, explains Gossage, while reducing the chances of crop burn under high light conditions. Diffuse light can also penetrate deeper into a plant canopy.

Looking at the crop grown in this greenhouse, Derek Schulze and Michelle Smith from Niagara College co-led the study with research assistants, Heliene staff and Marco de Leonardis of Freeman Herbs.

Temperature, relative humidity, dew point and chlorophyll content were not significantly different between the sections throughout the study. Photosynthetic active radiation (PAR) levels did show significant differences throughout the study, with control having the highest, a ‘strip’ (length-by-length) arrangement of modules being second highest and grid (checkerboard) arrangement having the least PAR.

As stated in the study summary, “interestingly, the higher light levels for the control section did not turn into significant gains in growth characteristics. The only observable difference was that plants grown under the strip configuration panels were trending towards being more compact and denser, which often translates into a higher quality product. Factoring in some of the crop variability experienced, it can only be concluded that the crops were not significantly impacted by growing under the solar panels. It should be noted that the higher light levels of the control section could potentially translate into more carbohydrate production and as such, further study would be advisable using a crop with more significant carbohydrate sinks.”

Gossage says yields were similar in the Heliene section compared to conventional sections of the greenhouse and there were some indications that the plant basil in the study grew a little more densely. This is likely because of the diffusion of light.

In terms of the two module arrangements, Gossage says that plant performance is similar with both, but the grid pattern is more expensive because it involves splitting cells and generally leads to some cell breakage. They only use the strip arrangement now.

He adds that the modules at Freeman are still functioning very well. Heliene hopes to do another study in 2023 with Freeman using the existing modules but with different crops.

U.S. project

In 2021, Heliene did a project in the State of Washington. Gossage notes that for new greenhouse builds in the U.S., there is a Solar Investment Tax Credit available to offset the initial investment for use of conventional solar panels and those including Heliene technologies (Gossage is not aware of any other solar glass technologies eligible under this program) that integrate seamlessly on the roof.

The solar modules used for this greenhouse build project (completed by a Canadian greenhouse contractor) contained four strips of cells instead of two, says Gossage, which is a 66 per cent solar-cell coverage of the glass for more power production. Due to the higher level of shading with this situation, the cells were mainly distributed in roofs that cover distribution and packing areas.

New technology

Meanwhile, Heliene is partnering with New Mexico-based UbiQD on a new “light curtain” containing a light-shifting nano coating. To this point, these curtains have hung under the glass roof of greenhouses with a shelf life of two to three years, explains Gossage.

In these curtains, green and blue wavelengths of light that plants don’t use are converted in a prism fashion using UbiQD’s nanotechnology into red and yellow wavelengths that plants can use. Gossage says there are many independent studies showing that this technology results in 10- to 20-per-cent yield increases in greenhouse crops.

“The UbiQD nanotech, known as quantum dots, is placed between two pieces of glass with our solar cells integrated alongside,” he says. “Having our technology integrated dramatically increases the typical two- to three-year lifespan of the quantum dots to 25 years. We are currently doing two greenhouse trials in Ontario, in tomatoes and cucumbers.”

One of these trials is at D.T. Enterprise Farms in Ruthven, Ont. “D.T. Enterprises is excited to support Heliene’s Generation 2 Greenhouse Integrated Phovtovoltaic (GiPV) solution,” says vice-president Tony Mastronardi. “D.T. Enterprises is embarking on a significant drive to decarbonize its facilities as well as its vehicle fleet. We have a strong desire to generate clean power onsite, as we strive to reduce our reliance on natural gas and electrify our processes.”

Powering up

Indeed, as already mentioned, there is a serious electricity shortage in Canada’s greenhouse hotbed.

“The new electricity line that is being built for the Leamington area for 2026 is already oversubscribed,” Gossage reports. “This is a crisis and we are pleased to be part of the solution. A team from the University of Windsor is going to conduct a two-year grid impact assessment to better understand how Heliene’s technology can be leveraged as a ‘non-wired’ alternative to help fend off the power crisis.”

Gossage adds that ‘agri-voltaics’ are now really taking off in the U.S. This involves framed semi-transparent solar panels placed amongst the rows of field horticultural crops.

“Much of the prime solar locations are coincident with prime agricultural lands” he says. “Agri-voltaics allows land to be used to produce crops and electricity at the same time in order to keep farmers farming and diversify their income. We are starting to learn all sorts of ancillary benefits about this nascent practice including more efficient water usage, less extreme heat exposure and of course greater energy and food security. We are helping to plan an inaugural agri-voltaics conference on December 8 hosted by Western University.”

Print this page