As the only person growing tomatoes, capsicums and cucumbers at the edge

of the Outback, Dave Pratt is a little bit of a celebrity – especially

here in Canada, from where he hails.

As the only person growing tomatoes, capsicums and cucumbers at the edge of the Outback, Dave Pratt is a little bit of a celebrity – especially here in Canada, from where he hails.

|

|

| Grower David Pratt, a graduate of Niagara College. ALL PHOTOS COURTESY DAVID PRATT/SUNDROP FARMS Advertisement

|

Pratt is head grower at Sundrop Farms, situated near the town of Port Augusta in the state of South Australia, 300 kilometres from the closest major city. Being so far away from “civilization” means it takes a minimum of seven days to get anything delivered, so there must be backup in place for absolutely everything.

“I like to call it ‘Growing All By Myself,’” Pratt quips, “but I love the pressure. This is a great success and it will continue to be.”

Being 20 kilometres from a small mining town on the edge of the Outback also means that receiving freight is expensive, but shipping produce back to the city is actually inexpensive: many refrigerated trucks that bring food to Port Augusta return to the city empty. Sundrop Farms produce is currently sold at some stores, but mainly at the farmers markets in the city.

The challenges don’t end with the remote location. Procuring support and services for greenhouses anywhere in Australia is a bit tough at the best of times, as the Australian greenhouse industry is very young. There are fewer than 100 hectares of medium-high-tech greenhouses in the entire country, Pratt notes.

REMOTE LOCATION CAN BE AN ASSET

However, he sees at least one advantage to being located on the edge of the Outback – insect and disease pressures from neighbouring greenhouses are nonexistent.

|

|

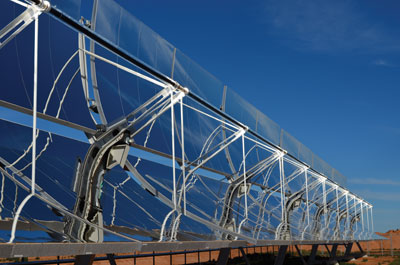

| Power from the sun.

|

What drew Pratt to Sundrop Farms was the ability it afforded to use abundant renewable resources to create self-sustainable agriculture.

“We’re using sunlight and seawater to create electricity, heating and fresh water for the greenhouse,” he says.

“It’s also exciting because there are very high light levels here that provide very high production. It’s really impressive what a crop can do when given consistent sunny days.”

The biggest challenge for Pratt in working within an innovative but small project is how differently things work compared to a large-scale commercial greenhouse.

“You would think that going from my previous position in Ontario managing 3.5 hectares to managing 0.2 hectares here would be an easy switch, but nothing could be further from the truth,” he says.

“Many ideas need to be tried in detail first and so implementing change can be a slow process. You also can’t justify the costs of many useful and helpful materials, like a shredder for cleanout. We remove the old crop by hand.”

Pratt has heat buffer tanks, fresh water tanks, and electricity just like any other greenhouse would have, but the water comes from the sea, and is used for more than direct vegetable production.

SYSTEM UTILIZES SOLAR ENERGY TO REMOVE SALT FROM SEAWATER

Sundrop’s “thermal desalination” plant uses only solar energy, a system wherein heat is used to remove salt from the seawater. (The other main type of desalination system is “reverse osmosis,” which uses pressure generated with electricity to force the salt out.)

Sundrop’s “solar thermal desalination” unit uses generated heat from a concentrated solar collection trough, and produces an average of about 10,000 litres of fresh water a day (water is also collected from crop drain runoff).

All the salt byproducts of different types are used in fertilizer or animal feed. Nothing is wasted.

Pratt uses water and appropriate hydroponic crop setup to handle the extreme heat during two to three months a year – when temperatures in the area can reach above 48 C and the relative humidity goes below five per cent.

The air in the greenhouse is cooled using evaporative cooling. This system is used in arid regions and involves large fabric pads that are kept moist, with fans used to evaporate the water in the pads. This cools the air surrounding the pads.

“It depends on the ambient relative humidity, but within a pad-and-fan greenhouse, it can be 15 degrees cooler than outside,” Pratt says.

Winter heating requirements are minimal of course, but the area around Port Augusta can experience light frosts with temperatures of between 0 and 2 C. “If heat is limited and there are cloudy periods, our backup boiler/generators can be used,” explains Pratt.

ALL-GLASS EXPANSION IS NOW UNDERWAY

Sundrop Farms is expanding its current facility by eight hectares. The new all-glass greenhouse will feature the most sophisticated temperature control technologies. “Plastic pad-and-fan greenhouses can be used on a small scale,” Pratt notes, “but for larger projects, there are much better options.”

Commercialization of their greenhouse technology is also moving forward. “At the moment,” says Pratt, “we are committed to expanding our own facility in Australia, but we are currently in discussions regarding projects in other arid climates, such as the Middle East.”

Pratt grew up in the Kitchener-Waterloo area of Ontario, well away from the greenhouse-intensive areas of the province (the Leamington and Niagara regions), and with no family greenhouse industry connections.

He says it was the combination of all the fields that are involved within the greenhouse industry, including chemistry, botany, engineering, programming and agriculture, among others, that drew him to it as a career choice.

“Being able to be in a warm climate during cold Ontario winters also did not hurt,” he quips.

In 2007, Pratt graduated from the Greenhouse Technician Program at Niagara College, an experience that he says offered “everything I needed to get my foot in the door within the industry.”

PROGRAM STRENGTH IS ITS DIVERSITY OF CLASSES

Pratt thinks the diversity of classes offered at Niagara is in a league of its own – the school offers studies in climate, vegetables, floriculture, water management, IPM, computer operations, direct software training, and more.

“Not only do they have a glass, semi-high tech greenhouse where you learn the basics, but at the end of the graduating year, there is a field trip to Leamington,” he notes. “This gives the students an opportunity to learn from the experts and get up close and personal with actual operations. When I visited a large-scale commercial hydroponic pepper greenhouse, I knew from that day on what I wanted to do.”

One of his instructors at Niagara College was Olga Piedrahita. “The other instructors and staff at Niagara College were very helpful, but Olga is the one that pushes you past what you think you are capable of, and then pushes you even further,” says Pratt.

For her part, Piedrahita says Pratt was a student who knew how to socialize and have fun, but who often opted for the most challenging projects – and who was very determined to get a job in vegetable production.

“During the yearly trip to the Leamington area, he left resumés at every stop,” she remembers. “He talked to anyone willing to listen. This persistence paid off with his first job offer soon after finishing school (at Sunmaster Produce). He worked so hard during his first years that he actually had a mattress at the greenhouse in order to keep a close eye on his first pepper crop.”

Indeed, the year after, Pratt achieved a record-setting yellow sweet bell pepper harvest of over 33 kilograms per square metre.

In 2009, he also helped implement a three-acre expansion at Sunmaster.

It was during his four years there, however, that the greenhouse industry in Ontario faced many challenges – fluctuating energy costs, growth in overall operating costs and shrinking produce prices.

“This led me to start researching new ideas and new technologies,” Pratt explains. “In 2010, I had the opportunity to start my career with Sundrop and it fits well with these interests.”

MAINTAINING CONTACT WITH THE COLLEGE

Piedrahita appreciates the way Pratt has always maintained contact with the college.

|

|

| Pratt checks young plants.

|

“He has come back to talk to students regularly and to encourage them to follow their dreams, and in particular, to consider a career in the greenhouse industry,” she says. “He is very passionate about this.

“The challenges that David has experienced in . . . Australia are many, since he is at the cusp of innovation,” Piedrahita adds. “David has had the challenge to adapt the current greenhouse vegetable production technology to a very different environment. He’s also had to develop new growing methods, resulting in increased production and quality by taking advantage of the extreme conditions.”

David was nominated in 2011 and again in 2012 for the Premier’s Award in Ontario in the “Young Graduate” category. He won the award last year.

“We at Niagara College hope that the judges will understand the impact of the innovations being developed by the Sundrop team that includes David as the head grower,” Piedrahita says in our interview conducted prior to the award announcement last fall.

In terms of career plans, Pratt says there is no escaping the fact that growers must stay close to their greenhouses.

“This, of course, means that you must really like the area where the greenhouse is located. Australia has a strong economy, it’s beautiful and I truly believe in the future of this technology.

“I am looking forward to the exciting times ahead here at Sundrop Farms.”

Treena Hein is a freelance writer in Ontario.

Print this page