An update of available biomass combustion boilers

This update of available biomass combustion boilers is a follow-up to our popular “Biomass Combustion 101” by Dr. Fernando Preto of CanmetENERGY. Here, we drill down through the mass of information provided by equipment suppliers to offer an overview of technologies, specifications and applications to sawmillers, panel mills, pallet makers and other forestry professionals involved in the emerging biomass sector. Compiled by Colleen Cross.

|

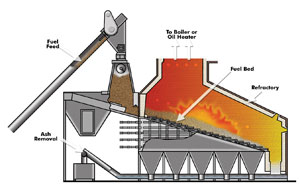

| Above: The Wellons Stepped Grate combustor burns bark, sawdust, wood chips, wood pellets, forest residuals and agricultural biomass. |

BFI EVEN BURNS BURIED BIOMASS

BFI (Falmac Boiler) manufactures stoker grate and bubbling fluidized bed boilers with capacities in the range of 250 kW to 20 MW, and also offers cogeneration (thermal plus electricity). The boilers, which suit small commercial and industrial applications, burn wood chips, wood pellets, agricultural waste and municipal solid waste. BFI manufactures fluidized bed biomass power plants and offers turnkey biomass power plants that produce thermal and, optionally, electrical energy (cogeneration); these systems are fully automated and fabricated in modules for easy transportation and installation. They can burn biomass with higher levels of moisture, even buried biomass. BFI also offers custom designs of its own systems according to client specifications. www.biomasse.ca, c.asselin@falmec.qc.ca

|

| With its moving grate, Blue Flame’s Chain Grate Stoker can burn various fuels without clinkers. |

BLUE FLAME BURNS TROUBLE FREE

Blue Flame Stoker’s Chain Grate Stoker is available with a capacity range from 300 kW to 6 MW for small commercial and industrial applications. The versatile Multi Fuel Stoker burns wood shavings, wood chips, wood pellets, municipal solid waste, corn stover, flax straw, agricultural waste with moisture content up to 50%, and fuel sizes from four inches down. Its overfeed system is designed for trouble-free feeding of densified or loose biomass, and its moving grate enables it to burn various fuels without clinkering problems. A user-friendly PLC control panel manages all the stoker functions from a single touchscreen. Features include a fully modulating system with turndown ratio of 6:1 with “Hold Fire” option; Type “C” or HRT style boilers, built to ASME code and ready for hot water or steam with pressures up to 300 PSIG; a Multi cyclone dust collection system that is up to 90% efficient; an automated ash and soot removal system; and a compact design that requires minimal floor space for installation. www.blueflamestoker.com, info@blueflamestoker.com

|

| Combustion Expert’s thermal power units use any kind of residues – from sawdust to small logs – with up to 60% moisture content. |

COMBUSTION EXPERT THINKS INSIDE THE CONTAINER

Combustion Expert Inc. is a manufacturer of biomass combustion systems, including watertube, firetube, hybrid, electric and thermal fluid boilers, for commercial and industrial companies. System capacities range from 1 MW (100 BHP) to 30 MW (3000 BHP). From sawdust to small logs, the thermal power units use any kind of residues with up to 60% moisture content. Either for heating or thermal process, different advanced technologies can be used according to the client requirements. The system mainly consists of the boiler, the combustion chamber and the wood-feeding system. This system is generally a combination of a hydraulic mobile rake system, shaftless screws and the feeder. Combustion Expert delivers turnkey projects as well as existing system conversion services. For more versatility, systems can also be assembled in a container to avoid building costs or in a mobile unit for temporary use. The product also features an automatic ash exhaust system and remote monitoring, and meets low emission rates while maintaining efficient combustion. www.combustionexpert.com, info@combustionexpert.com

|

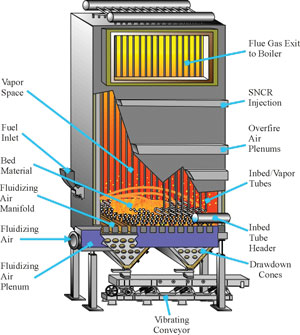

| EPI’s fluidized bed boiler systems convert renewable biomass and other solid or liquid fuels into steam energy. |

ENERGY PRODUCTS EVOLVING

With nearly 35 years of operating experience and more than 80 fluidized bed energy system installations, Energy Products of Idaho (EPI) develops and implements fluidized bed gasification and combustion of biomass and waste fuels for the production of green power while reducing greenhouse gases. Early EPI systems used biomass waste to generate process steam and/or hot gas for direct-fired dryer applications. The company provides fluidized bed energy systems that range from 2 MWe (8 MW thermal) up to 50 MWe (200 MW thermal). Application of this state-of-the-art technology has now expanded to include independent power production facilities and utility power boiler conversions from antiquated stoker and grate technologies. EPI systems have logged more than five million hours of operating time using such diverse fuels as refuse-derived fuel, board plant waste, demolition waste, urban waste, waste paper, paper sludge, sewage sludge, coal, waste plastics, chicken litter, rice hulls, peat, lignite, cow manure, railroad ties, tires and agricultural waste products. www.energyproducts.com, epi2@energyproducts.com

FINK AND KÖB TURN WASTE WOOD INTO DOLLARS

Fink is the authorized sales agent for KÖB, which manufactures the Low-Particle Firing Pyrot Rotary Combustion Chamber Boiler and the Pyrtec Moving Grate Combustion Boiler. These fully automatic chip and pellet boilers are available in sizes from 80 kW to 2500 kW (270,000 to 8.5 million BTU).

The Pyrtec takes wood fuels ranging from dry pellets to moist forest wood chips, while the Pyrot uses dry woodchips, wood pellets or wood byproducts. The equipment meets commercial, institutional and/or industrial heating requirements, and the company’s specialty is installing large heating systems. Fink is experienced in biomass-based systems for district heating grids, woodchip and pellet systems for municipal buildings and local heating networks.

The Pyrot is environmentally friendly, with low emissions. The Pyrtec offers outstanding controllability of output and fully automatic de-ashing and cleaning. Unlike oil and gas, wood is CO2-neutral and renewable. When used with KÖB modulating output controllers, the burners can achieve more than 90% efficiency. www.finkmachine.com, info@finkmachine.com

EFFICIENT KMW ENERGY SYSTEMS

KMW Energy Inc. specializes in the engineering and supply of thermal and combined thermal and power systems. Each KMW Energy system is custom designed and engineered to suit the requirements of each application, with thermal energy outputs ranging from 150 boiler hp to 4000 hp and power generation from 1 MW to more than 25 MW. Successful combustion/gasification tests have been made using KMW Energy test units installed at Ortech International in Mississauga, Ont., and CANMETEnergy Technology Centre, Ottawa, on such materials as refuse-derived fuel (RDF) from municipal waste, scrap tires, construction debris, waste paper, peat, chicken litter, corn stover, rice husks and mill sludge. The KMW Energy

system, designed as modules based on standard components, has been created for optimum combustion/gasification and operating efficiency, and for quick and smooth assembly. www.kmwenergy.com, info@kmwenergy.com

|

| Hurst’s biomass steam and hot water boilers and direct-fired STAG units burn everything from wood to sludge. |

HURST HELPS BIOMASS-TER CARBON FOOTPRINT

Hurst Boiler & Welding Company offers a series of biomass steam boilers, hot water boilers and direct-fired STAG units for alternative solid fuel systems. The Biomass product line is available with such options as Flat Grate Stokers, Underfeed Stokers and Traveling Grate Stokers to meet all biomass system requirements. The company provides medium-sized steam and hot water boilers for the production of heating and domestic hot water, steam for process and heating as well as power generation for all sizes of industrial, commercial, and institutional/industrial applications. Steam capacity range is from 0.78 tons per hour to 57.2 tons per hour. The latest addition to Hurst’s series is the Reciprocating Grate Stoker with automated ash removal. This unit offers solid fuel combustion and allows mechanical replacement of fuel with the least number of moving parts possible. Its efficient, multi-fuel design is offered in various configurations to utilize a wide selection of solid fuels: wood, coal, bark, construction debris, nuts, shells, husks, paper, cardboard products, hog fuel, sawdust, shavings, sludge and agricultural biomass. The Hurst Biomass-ter features a CO2 Neutral Release and PLC-based total systems monitoring. All Hurst factory stokers are cast from high-quality steel alloys and mounted on a robust undercarriage system. www.hurstboiler.com, jhurst@hurstboiler.com

JANSEN ENGINEERS AND UPGRADES

Jansen Combustion and Boiler Technologies, Inc. provides engineering evaluations, CFD modelling, boiler retrofit/modifications, engineering/design and design. The company provides engineering and equipment to upgrade and modify existing biomass and waste-fuelled boilers, including stoker grate units and fluidized bed boilers. Jansen has provided upgrades on biomass and combination fuelled fossil/biomass boilers ranging in size from 60,000 lb/hr steaming rate up to 800,000 lb/hr. Generally its work has been in the industrial and independent power-producing industry. Its engineering includes detailed evaluation/characterization of the boiler, design of cost-effective combustion and heat transfer solutions, and detailed design and equipment supply. Jansen’s upgrades provide increased steam production from biomass and waste fuels, improved air emissions, improved boiler efficiency, and reduction/elimination of fossil fuel co-firing. Engineering analysis includes in-house computational fluid dynamic (CFD) modelling of each individual boiler, steam/water circulation analyses that include ultrasonic flow monitoring of critical boiler circuits, design engineering, equipment supply and project management.

Capacity range is from 5 to 100 MW (heat input) and fuel types include biomass, waste wood, hog fuel, mill sludge, TDF, OCC, MSW and/or RDF. In providing customized, engineered solutions, Jansen’s focus is to help customers improve operating performance and fuel economy of boilers that handle biomass and/or waste fuels in the areas of efficiency, fuel-burning capacity and air emissions. www.jansenboiler.com, jansen@jansenboiler.com

SIMONEAU’S HYBRID AND A-TYPE OFFER MANY APPLICATIONS

The Hybrid solid fuel boiler integrates a full waterwall furnace with a steam-generating firetube section and maximizes heat transfer through an extensive radiant and convective surface combining watertube and firetube steam generation. Capacity ranges from 5000 PPH to 40,000 PPH. Hybrid boilers are best used when a byproduct is readily available as an alternative fuel (wood, manure, biomass, bagasse, coal, etc.). Installations offer economic benefits in addition to the fuel savings on such expenses as disposal fees, tax incentives and environmental implications. Typical industrial applications include manufacturing and processing facilities, pulp and paper, sawmills, petrochemical, universities, hospitals, greenhouses and ethanol plants. The A-Type watertube is a symmetrical, well-balanced boiler with a large furnace volume, designed with a centred steam drum and two lower mud drums. The A-Type configuration allows increased capacities (up to 250,000 PPH) and higher operating pressures (up to 1500 PSIG) than other watertube designs. Given its large design capacities, the A-Type is well suited for cogeneration and solid fuel firing (with an open bottom furnace). Typical industrial applications include manufacturing and processing facilities, pulp and paper, chemical, and petrochemical. www.groupsimoneau.com, info@groupsimoneau.com

HIGH EFFICIENCY, LOW EMISSIONS TEAFORD TRADEMARKS

High efficiency, low environmental emissions, and generous sizing are the trademarks of Teaford Company biomass-fired boilers. These units are designed with multi-stage burners, and can be provided in the following sizes: field-erected boilers with up to 300,000 PPH steam output and superheated up to 1200 PSIG/1200 F, and package boilers with up to 70,000 PPH steam output and superheated up to 1200 PSIG/1200 F. Teaford’s field-erected and package boilers feature saturated or superheated steam; high- and low-pressure designs; tangent tube, tube and tile, and membrane wall designs; wet and dry fuel systems; wet fuel up to 55% moisture content wet basis; reciprocating grate; auxiliary gas or oil burners; air preheaters and economizers; pollution control including ESPs; SCR and SNCR NOx reduction systems; and high combustion efficiency systems. Package boilers feature compact low-cost firetube designs; watertube designs for high pressure; combination watertube and firetube designs; high- and low-pressure designs; and complete turnkey plants. Teaford’s custom design of boilers can include many different options to meet individual site requirements while maintaining high efficiency and low cost parameters. Most Teaford systems are for industrial operations that use steam in dry kilns, heat exchangers, dryers, for conditioning of materials and electrical generation/cogeneration. Some electrical generation users are power companies trying to get renewable energy as part of their overall electrical production, while others are single companies (universities, mills, etc.) powered by cogen systems. www.teafordco.com, www.teafordcanada.com

|

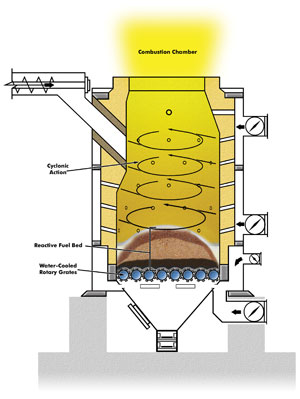

| Wellons’ Combuster Cell applications include sawmill and board plant energy systems, biomass fired electrical generation and CHP systems and direct-fired systems. The Stepped Grate Furnace suits the medium- and large-sized district heating systems used in hospitals and university campuses. |

WELLONS ON ITS WAY WITH TWO BOILER OFFERINGS

The Wellons group of companies offers two biomass combustion technologies to satisfy customer-specific fuel and thermal energy requirements: the Stepped Grate combustor and the Combustor Cell. The Stepped Grate combustor features a hydraulically operated fuel feeder and fully automatic hydraulic rake ash extraction system. It offers a capacity of 2 to 40 MW thermal and burns bark, sawdust, wood chips, wood pellets, forest residuals and agricultural biomass. Applications include sawmill and board plant energy systems; biomass-fired electrical generation and CHP systems; district or space heating using hot water, steam or thermal fluid; and direct-fired systems to provide hot gases to dryers for pellet plants, MDF or OSB facilities. The equipment suits medium- and large-sized district heating systems used in such applications as hospitals and university campuses.

With the Combustor Cell you can choose either an overfeed green fuel configuration with automatic ash removal or an underfeed dry fuel configuration with manual ash removal. Modular design of the unit in two- to six-cell configurations provides gross combustion input ranging from 4 to 140 MW. With a capacity of 3 to 73 MW for steam boilers, and 6 to 30 MW for thermal oil heaters. Suitable fuel types include bark, sawdust, wood chips, wood pellets and forest residuals. Applications include sawmill and board plant energy systems; biomass-fired electrical generation and CHP systems; and direct-fired systems to provide hot gases to dryers for pellet plants, MDF or OSB facilities.

For eastern North America see www.wellonsfei.ca, and contact info@wellonsfei.ca. For western North America, and the Combuster Cell, see www.wellons.ca, and contact sales@wellons.ca.

Print this page