CURRENT ISSUE

Spotlight on Harrow

This is a special year for the Greenhouse and Processing Crops Research Centre in Harrow, Ontario, as the world-renowned facility prepares to celebrate its centenary.

This is a special year for the Greenhouse and Processing Crops Research Centre in Harrow, Ontario, as the world-renowned facility prepares to celebrate its centenary.

According to a 75th anniversary report by Dr. Gordon Ward, the centre had several greenhouses before 1947, but they were mainly used for the production of tobacco transplants.

The first research greenhouse was built in 1948, with a focus on plant pathology. However, scientists at the centre had been studying greenhouse crop problems for several years before that. In 1942, Dr. L.W. Koch published a 12-page bulletin on diseases of greenhouse cucumbers that included suggested control measures.

Dr. Ward listed many of the early challenges tackled by the researchers, including powdery mildew problems, whitefly control, blossom end rot and grey mould, among others. He also referred to a 1956 report that noted “reasonable” tomato plant yields “of five and eight pounds for fall and spring crops, respectively.”

The Centre will host an open house on Saturday, Sept. 12, from 10 a.m. to 3 p.m. It’s expected to attract hundreds of growers, researchers and suppliers from across the country. Included will be guided field, greenhouse and facility tours, displays and demonstrations, and a barbecue lunch.

So, as we look forward to learning more about the history of greenhouse research at Harrow later this year, this month’s feature is an overview of some of the latest research initiatives. Included are energy use optimization projects, studies of one of the most effective generalist predators in the industry, researching the effects of water stress on fruit quality, and identifying low-risk materials in Phythophthora control, among many others.

|

|

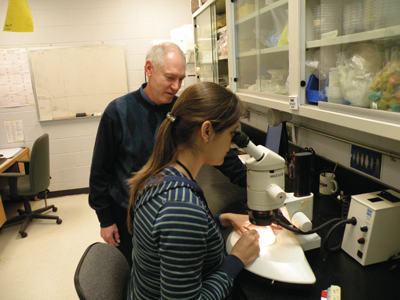

| Drs. Les Shipp and Rosemarije Buitenhuis, counting mites after plant washing a commercial trial sample | |

|

|

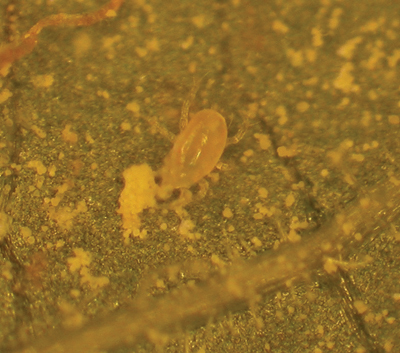

| Swirskii can survive on pollen in the absence of prey. (PHOTO by AAFC)

|

HELPING YOUR PREDATORS KEEP THEIR PREY AT BAY

Amblyseius swirskii continues to impress researchers with its predatorial versatility … and healthy appetite.

“It’s the new mite on the block,” said Dr. Les Shipp. “Swirskii works so well because it’s a generalist predator. It will feed on thrips, but it will also feed on the eggs of whitefly. And that’s different from the other predatory mites now in use.”

This generalist predator was the subject of a pair of recent studies at the GPCRC and proved itself quite effective.

The first project looked at swirskii’s effectiveness on russet mite on tomatoes. It has already proven itself in controlling whitefly and thrips. However, it hadn’t been used as a primary control agent for mites. There is anecdotal evidence from Europe that swirskii is effective in controlling broad mites on sweet peppers.

“We did some lab trials and found the potential is there,” said Dr. Shipp. “We’re at the point where that work now needs to be done in our research greenhouses to see what introduction rates would be best, and where they should be released and how often.”

Visiting scientist Dr. Rosemarije Buitenhuis also looked at the effectiveness of swirskii as a control agent for thrips on ornamentals and, in particular potted chrysanthemum.

One study looked at its dispersal effectiveness. If it were applied on a plant that wasn’t in direct contact with other plants, would the mite be able to move about the crop? “Could you place the mite on one plant and have it move to other plants, and on how many plants in the crop would you have to place the mites on?”

What they found was that swirskii doesn’t disperse well. It didn’t matter if thrips were present on the plants or not, though having thrips meant the mites would survive longer.

However, if the plant canopies were touching, swirskii would move from one plant to another. “They need bridges to get across,” says Dr. Shipp. “If they walk down the plant and into the soil or wherever, they don’t survive.”

It’s important with mites that the plants be touching. “It works well with cut flowers or at a stage with potted crops where all the foliage is overlapping.”

They also found that if you provided swirskii with cattail pollen, they would survive from egg to adult and would lay eggs. “The mite can live just on pollen, which is important.”

This is why the mite works so well in pepper crops, because there is a pollen source. However, it’s not as effective with cucumbers because there’s no pollen to sustain it when thrips numbers are low.

Dr. Shipp is hoping to study how best to provide supplemental food sources in the crop. There have been some studies overseas, but nothing done locally. “Providing alternative food in the crop will mean the mite will work even better.”

They’re also studying the effectiveness of mites during different seasons. Swirskii was originally found in the Mediterranean region, “so it likes hot and dry conditions.” It does great in the summer, but how effective will it be in the winter?

Similarly, cucumeris is from a more temperate climate, so it may do better in the winter.

“We need to find these answers. We can get good control in the summer. But it’s always been more difficult, whether it’s ornamentals or vegetables, to get good biological control in the winter.”

The researchers have been working with commercial ornamental growers, having them apply both cucumeris and swirskii on their crops. Sample plants were sent to Harrow to see if the mites are surviving and whether they’re multiplying. They’d like to repeat this study in both summer and winter, to see if there’s a difference in how the mites perform. “Does one work better at one time of the year or the other, or are they both the same?”

Flower growers are increasingly using biocontrols, but they don’t always know if they’re working or if there is a pest problem to begin with. “They’re putting them on early, and they’re applying them every week or every other week. It’s great that they’re doing it, but we need to give them feedback that they’re getting value for the money they’re spending. We can help them with the establishment of mites in their crops.”

Over the winter months, pest levels aren’t as high, “but you still need to have an effective control in place because if you don’t, the pest populations will get out of whack when things get warmer.

The swirskii studies were supported by grants from Flowers Canada Ontario and the Matching Investment Initiative program of Agriculture Agri-Food Canada.

In another project, the researchers studied whether bee vectoring of Botanigard (Beauvaria bassiana, a microbial fungus that attacks only insects) would have any effects on other beneficials. Also involved in this project were Dr. Jean Pierre Kapongo, NSERC Visiting Postdoctoral Fellow, Dr. Peter Kevan of the University of Guelph, and Shalin Khosla, greenhouse vegetable specialist with the Ontario Ministry of Agri-culture, Food and Rural Affairs. The work was supported by funding from several Ontario greenhouse vegetable growers and the MII program.

The trials included Encarsia, Eretmocerus, Aphidius colemani and swirskii. The study found no harmful effects. “We looked at their efficacy, their parasitism and predation levels, and didn’t find any difference in their mortality and predation and parasitism levels with respect to whether or not they were exposed to bee-vectored Beauveria.”

They also worked with Orius. Closely related to Lygus, which is impacted by Beauvaria, Orius was found to be more negatively impacted. However, of those Orius that survived, there was no impact on their predation levels.

In another trial using commercial greenhouses, it was found that the bees were able to carry the spores throughout the crop and to the far end of the rows.

Dr. Shipp is also working with McMaster University psychology professor Dr. Reuven Dukas to study the learning behaviour of bumblebees. They will be working with pepper plants.

“We want to understand just how they learn with respect to foraging and finding nectar,” says Dr. Shipp. “How does the bee actually decided where to go to find their food source, and if they do learn, will they go back to the more productive plants? What sorts of variables affect the learning behaviour of bees?”

|

|

| Dr. Tom Papadopoulos is conducting water stress trials.

|

WATER STRESS AND FRUIT QUALITY: A CHALLENGING BALANCING ACT

Dr. Tom Papadopoulos headed up a national research project that studied organic vegetable strategies. The three-year project has wrapped up, and the final report is now being finalized.

Working with him were Dr. Xiuming Hao (AAFC) and Shalin Khosla (OMAFRA) of GPCRC, and Drs. David Ehret and Wei Lin at the Pacific Agri-food Research Centre (AAFC) in British Columbia.

The team looked at the three major crops – tomatoes, cucumbers and peppers – and a variety of treatments, including four liquid feeds and four media. The goal was to develop completely integrated production systems.

“We finished with peppers last year, and I’m now writing the report,” said Dr. Papadopoulos. “We had pretty good results. It looks promising.”

Project sponsors included the Ontario Greenhouse Vegetable Growers, the B.C. Greenhouse Growers Association, AgrowChem Inc., CH2O, Agrogreen Canada Inc., VGROVE Inc; their contributions having being matched by the Matching Investment Initiative program of Agriculture and Agri-Food Canada.

He’s currently working on two projects, both with AAFC colleagues.

Dr. Papadopoulos is involved in a plant-based environmental control project to improve energy efficiency. He is working on nutritional strategies associated with the project. The project is headed by Dr. Hao.

Examining the effects of water stress on fruit quality – Dr. Papadopoulos is also working with Dr. Ehret on a project studying different aspects of tomato fruit quality. The goal is to develop a modelling program that will allow growers to predict fruit quality depending on their production choices with respect to environmental control, nutrition and irrigation.

“My part of the research is focusing on the effects of water stress on fruit quality,” said Dr. Papadopoulos.

Research has shown, and experience has confirmed, that you get firmer fruit when a plant is stressed for water. “Everything is more concentrated. The fruit has less water and the level of dry matter is greater. The sugar content is higher, all the flavour attributes are higher, and the fragrance is more intense.”

Growers can create water stress by giving less water to the plants. However, this can be tricky. “You cannot easily regulate the amount of water that is available to the plant in a consistent way,” explained Dr. Papadopoulos. “If you try to live a little dangerously by providing lower levels of water, it often doesn’t take much – perhaps a cloud moved away and it is now brighter and warmer, or ventilation levels were changed – to have conditions move below an acceptable threshold.”

When this happens, problems often develop, such as blossom end rot.

If water levels get too low, the plant might begin wilting. If leaf stomates close to protect the plant from dessicating, the plant will no longer absorb carbon dioxide and the plant will not be as productive.

|

|

| Dr. Xiuming Hao, with a fruit growth sensor measuring the diameter of a tomato. | |

|

|

| Cherry tomatoes in one of the research greenhouses.

|

REDUCING INPUT ENERGY PER UNIT OF PRODUCE

Dr. Xiuming Hao is leading a four-year research project to improve energy use efficiency in greenhouse vegetable crop production.

The work began in 2008. Also involved with Dr. Hao are AgCanada colleagues Dr. Martine Dorais at the Laval University, Dr. Tom Papadopoulos of Harrow, and Dr. David Ehret of the Pacific Agriculture Research Centre.

Greenhouse crop production in Canada is very energy intensive. In 2005, according to StatsCanada, the industry consumed more than $260 million worth of energy. With the price increases in the last few years, energy costs now account for between 20 and 40 per cent of production costs with greenhouse vegetables.

Allowed to continue, these costs could threaten the sustainability of the industry.

“The goal is to reduce the input energy per unit of produce,” says Dr. Hao. This can be achieved by either reducing energy consumption without affecting quality or yields, or by increasing yields while maintaining the same energy consumption. “Either way, you can achieve the same goal.”

The project has four components:

1. Creation of dynamic greenhouse temperature control strategies. – Simply lowering 24-hour temperature averages to conserve energy is counterproductive, as energy savings are more than offset by delayed fruit production and reduced early yields. The current research will develop new dynamic plant-based temperature control strategies with temperature integration “by exploring the special characters and the natural adaptability or tolerance of fruit vegetables to variable climatic conditions,” explains Dr. Hao.

Researchers will determine just how much you can either drop or raise air temperatures before affecting the plant. “We have to know the low-temperature limit and the high-temperature limit.”

A photosynthesis-model-based temperature integration strategy will be developed to further improve energy efficiency. The dynamic temperature strategies based on air temperature or crop canopy temperature will be evaluated under semi-commercial conditions to study their effects on greenhouse tomato and cucumber growth, photosynthesis, yield, microclimate and energy consumption.

2. New lighting strategies, including the use of LEDs – Dr. Dorais will develop new supplemental lighting strategies by studying the effects of light quality and the distribution pattern on greenhouse vegetables with LED lighting.

Dr. Hao has been doing some work with grow pipes, supplemental lighting (including LEDs), and nutrient optimization with mini-cucumbers.

The supplemental lighting speeds up plant growth, and this means more nutrients will be required.

High pressure sodium (HPS) lights have more lighting in the yellow spectrum, and the LEDs were added to increase the blue range.

The grow pipe improved the microclimate and yields of the mini-cucumber crop. Normally with high-wire production, the mid-canopy is the coolest part of the crop. The grow pipe provides a more uniform vertical temperature profile.

3. Online crop monitoring systems – Dr. Ehret is developing an online system to automatically monitor plant growth, water uptake and leaf carbohydrate status for plant-based environment control. “Once you know the carbohydrate levels, you can adjust your temperature, lighting and CO2 levels based on the carbohydrate status of the plant,” says Dr. Hao. For example, if a leaf is already saturated with carbohydrates, there’s no need to supply more CO2 to fix more carbohydrates. Thus, environmental control based on carbohydrate status can prevent unnecessary/wasteful CO2 usage.

4. Rootzone environment management strategies tailored to work with dynamic greenhouse climate conditions – Dr. Papadopoulos is researching how the rootzone environment can be manipulated to acclimatize plants to low temperature stress. Dynamic fertigation strategies, based on crop transpiration and water uptake, will be developed to optimize crop productivity under dynamic climate conditions.

Once all components are completed, the energy use efficiency of the developed dynamic environmental control strategies will be evaluated.

“This research will significantly improve our understanding of the effects of environmental factors on plant processes, microclimate, energy consumption, and energy use efficiency,” says Dr. Hao. “The plant-based environment control strategies or systems developed will ensure the sustainability and competitiveness of the Canadian greenhouse industry by increasing energy use efficiency, fruit yield and quality, and by reducing carbon dioxide and air pollutant emissions into the atmosphere, thereby helping Canada meet its commitment under the Kyoto protocol.”

|

|

| Dr. Ray Cerkauskas and OMAFRA greenhouse IPM specialist Gillian Ferguson check for yellow stem symptoms.

|

EYEING LOW-RISK MATERIALS IN PHYTHOPHTHORA CONTROL

Dr. Ray Cerkauskas is studying reduced risk materials to use in controlling a plant disease that potentially could be an issue for both greenhouse and field vegetable growers.

Phythophthora blight has been a problem in field vegetable crops in several states in the U.S., including some that border Ontario. Tomatoes, pepper and cucurbits are crops most often affected.

There have been isolated cases in Ontario in recent years. Dr. Terry Anderson, a GPCRC scientist, found the disease in a field squash crop in 1994. There have been subsequent field crop cases over the years, though not in substantial numbers.

It’s been found in a few Ontario greenhouses over the past two to three years. “It hasn’t spread too far,” says Dr. Cerkauskas, “but it is there.”

The Harrow researchers are comparing field disease and greenhouse disease isolates.

This is a fungal disease that is favoured by warm and wet conditions. Greenhouse grow bags, therefore, would be ideal sites for the fungus Phytophthora capsici.

The fungus is especially devastating for cucumbers – The fungus affects all three major greenhouse vegetable crops, but is particularly devastating for cucumbers. It would take only two weeks to destroy a crop.

U.S. field producers have a wide range of available chemical controls. These are being studied by Dr. Cerkauskas and his team to see how effective they are with greenhouse crops.

“We’re looking at reduced risk materials,” he explains, “but it doesn’t just include fungicides. There are some other materials I’m hoping to try that are derived from natural plant material. It’s interesting to try them here, because in the greenhouse we have much greater control than in the field.”

The registration process for new controls can take some time. That’s why the current research is so important. It will provide growers with access to good preventive measures in case the disease becomes a problem.

Another disease he’s studying is the yellowing of the plant stem that tends to occur towards the end of the crop cycle. It seems to affect yields as well. “Growers have noticed over the past couple of years that some of the older plants would have a more prominent yellow stem.”

Dr. Cerkauskas noticed that the samples often included large quantities of fusarium spores. He has taken isolates and prepared a spore suspension. This inoculum was poured at the base of the plants. “We will have to wait a long time for symptom development. It’s likely a latent infection in which you don’t get symptom expression until the end.”

Studying internal rot of greenhouse peppers – A third experiment is looking at internal rot of greenhouse peppers. This disease was first reported in Alberta and it is caused by a different species of fusarium. It only occurs on the inside of the fruit and there are no exterior symptoms. Three possible fungi have been reported in association with the disease, including Fusarium subglutinans, Fusarium proliferatum and Fusarium lactis.

“We’re focusing on control measures and early detection.”

The team is also studying European corn borer. It causes the same problems, “because you don’t see any symptoms developing.”

Both of the internal fruit rot studies are being carried out in collaboration with GPCRC entomologist Dr. David Hunt.

Dr. Cerkauskas works closely with Ontario Ministry of Agriculture, Food and Rural Affairs greenhouse IPM specialist Gillian Ferguson. She works with growers on a daily basis. If she sees something she can’t identify, the sample is brought to the research centre. “This is not academic blue sky research,” he says. “Because Gillian works with the growers directly, when we look at a problem, we know there has to be a proper and practical solution or information that will be of benefit to the growers.”

These projects have received funding from the Ontario Greenhouse Vegetable Growers association. In addition, the Pest Management Centre of AAFC Canada is helping fund the research on reduced risk materials for control of phytophthora.

|

Print this page