Features

Business

Labour

Special Series the workplace #2: Understanding substrate design

April 16, 2010 By Andrew Lee

In the second of six articles for Greenhouse Canada, Grodan® Crop

Consultant Andrew Lee provides an insight into the key features of

stonewool substrates and describes how, by understanding the basic

principles behind them, growers can gain maximum benefit from an

applied irrigation strategy.

In the second of six articles for Greenhouse Canada, Grodan® Crop Consultant Andrew Lee provides an insight into the key features of stonewool substrates and describes how, by understanding the basic principles behind them, growers can gain maximum benefit from an applied irrigation strategy.

|

|

| Good results begin with effective rootzone management. Advertisement

|

Rootzone management: In the first article of the series (December 2009, pg. 14), we looked into the process of water movement and transport within the plant and how the rootzone and climate interact in driving this process. We also touched upon the effects of water uptake on sunny and dark days and how the rootzone environment needs to be “steered” correctly in order to maximize the grower’s revenue, i.e., production and fruit quality.

Correct rootzone management can also assist growers in reducing input costs. One example is the increasing gas prices in Europe (Figure 1.0), which is forcing growers to look critically at energy inputs and ways to manage these without being a detriment to yield and quality. I would imagine the same situation currently exists in Canada. As a result of this focus, the average energy inputs in northern European greenhouses have fallen from 60 million3 in 2005 to 40-45 million3 (natural gas) in 2009. This has been achieved with the implementation of lower maximum pipe temperatures in winter, using less or no minimum pipe for humidity control and increased use of movable energy screens, and fixed anti-condensate films to insulate the greenhouses better against cold outside temperatures. Growers and consultants have set themselves ambitious targets to reduce energy input towards 30-35 million3 in the near future.

These actions that ultimately limit the energy bill, which can still be in the region 10 euros per square metre, ($16 Cdn) create a greenhouse climate that reacts differently. This, as we know from my first article, has implications for the rootzone management strategy.

|

|

| Figure 1.0: Gas price index 2002-2009.

|

In order to get the optimum crop performance with minimal energy input, the grower needs to make adjustments to the irrigation strategy. To do this correctly, he or she must understand the key design features of the substrate and what functionalities these deliver in practice. It’s not simply a case of a “wet bag” or “dry bag” at the cutting edge of greenhouse innovation. Understanding the design features of a substrate enables the grower to develop specific irrigation strategies using the greenhouse computer to manage WC and EC to pre-determined targets, set according to their wishes. The added benefit is that the substrate supplier is also able to deliver the most appropriate and targeted user advice in support of the product.

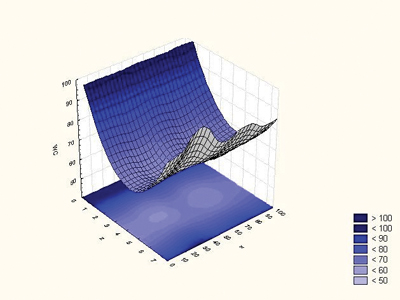

| Figure 2.0a: Typical WC distribution in dual-density horizontal fibre slab. |

|

|

|

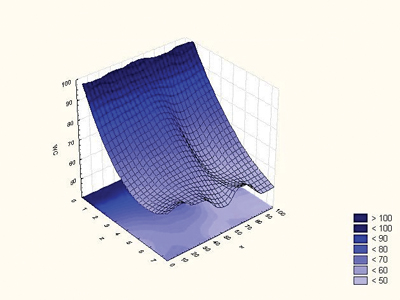

| Figure 2.0b: Typical WC distribution in a standard stonewall slab. |

|

|

|

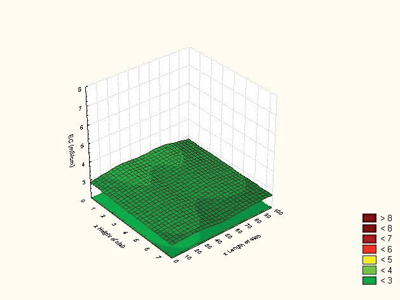

| Figure 2.0c: Typical EC distribution in dual-density horizontal fibre slab. |

|

|

|

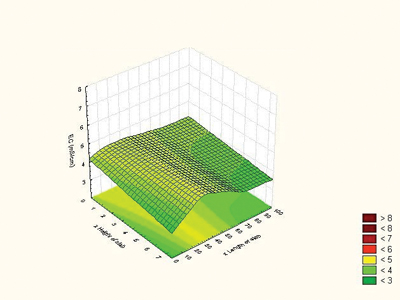

| Figure 2.0d: Typical EC distribution in a standard stonewall slab. | |

|

|

| Figure 2.0 notes: Slab dimensions 100 x 15 x 7cm. Drain holes cut at 0 cm on slab |

NEXT GENERATION OF SUBSTRATE TECHNOLOGY

A number of aspects related to substrate functionality in use are taken into account when designing slabs. Subtle design changes in fibre orientation, thickness and density result in substrates that perform differently in practice. The introduction of advanced hydrophilic fibres in substrates have further enhanced the performance of stonewool slabs as WC and EC are now distributed more uniformly over the surface of the stonewool fibres, rather like a thin film.

Key substrate functionalities that impact on how a substrate performs in daily life are uniformity, because without uniformity you cannot grow to a pre-defined strategy, you will always be making compromises for slabs that are too wet or too dry or for a slab EC that is too high or too low.

The Control Range WC is important because greenhouse crops require generative or vegetative steering, depending on their balance without being a determent to plant growth, root function, yield and quality. Consequently, the substrate needs certain minimum and maximum operating levels that can be tailored to the specific needs of the customer. The ability to restore desired day level WC quickly and easily depends on the re-saturation properties of the substrate and, in combination with the irrigation efficiency of the substrate, determines how the applied drip solution is utilized, for optimum EC control. For example, what proportion of applied irrigation is used to dilute the slab solution, what proportion replaces the old solution and what proportion runs directly to drain?

KEY FUNCTIONALITIES IN PRACTICE

In practice, growers require uniformity across the length and height of the substrate. This provides confidence, for example, that the substrate will not become too dry in the top layer and allows specific strategies to be implemented when steering the crop to maximize revenue but also limit costs, i.e., fertilizer inputs.

This key design feature is principally derived through the quality of the manufacturing process and the defined production tolerances. However, subtle design features can dramatically change WC and EC distribution in the slab. Figures 2.0a-d illustrates the WC and EC distribution for a tomato crop in two types of stonewool slab each given the same irrigation strategy. The pattern of WC and EC distribution across the length and height of the slabs is clearly different, the denser top layer clearly having a higher WC (Figure 2.0a) and lower EC (Figure 2.0c) compared to a standard slab (Figures 2.0b and 2.0d). Growers must therefore be aware of how evenly WC and EC is distributed in their chosen substrate to get the best out of them in terms of the applied irrigation strategy.

|

|

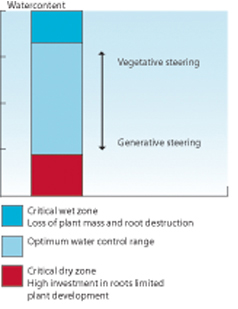

| Figure 3.0: Schematic representation of Control Range WC for glasshouse substrates.

|

Control range WC for substrates is represented schematically in Figure 3.0. Plant performance is optimized if the day level WC can be maintained within certain operating limits. Within these limits, growers make optimum use of inputs, i.e., energy. The lower limit maximizes generative steering and the upper limit maximizes vegetative steering. The degree of steering offered is dependent on substrate design.

Operation of day level WC outside these limits has a negative impact on plant performance. For example, we know that if day level WC is stabilized in the critical dry zone (Figure 3.0) proportionally more investment by the plant is put into root development at the expense of controlled plant development. If day level WC is stabilized in the critical wet zone, the result again is a loss of plant development and destruction of root quality. The energy input to the crop is not optimized in both scenarios. It is therefore important to know what the operating limits for control range WC are from your substrate supplier.

|

|

|

|

|

|

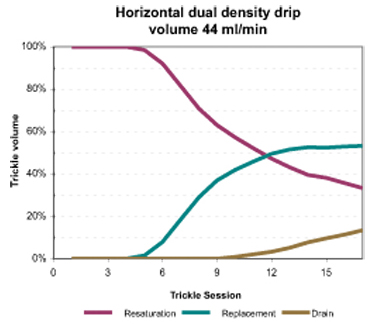

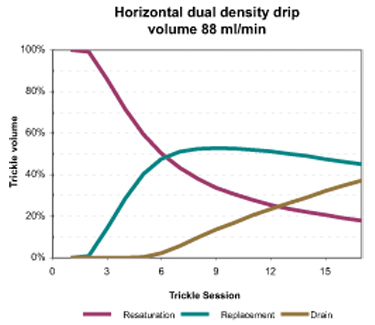

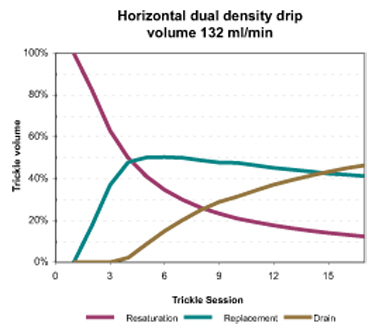

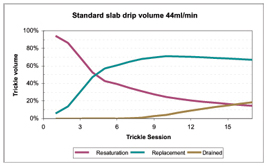

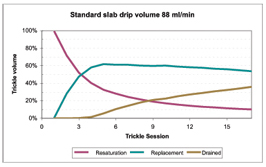

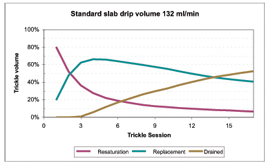

| Figures 4.0a-c

|

The re-saturation and irrigation efficiency of the substrate is clearly linked to the volumes of applied irrigation as shown in Figures 4.0a-f. Substrates react differently according to their design characteristics. It can be seen that the horizontal dual density substrate creates less drain than a standard slab and that larger irrigation volumes replace a greater proportion of the substrate solution. In practice, if you know the irrigation efficiency of the substrate you are using and how it reacts to different volumes of applied irrigation, you can implement an irrigation strategy that will achieve a specific slab WC and EC. Just as importantly, if corrective actions are required to level EC or adjust WC you will know what changes are required. This is an important functionality that has a large impact on start and stop times, hence energy saving measures.

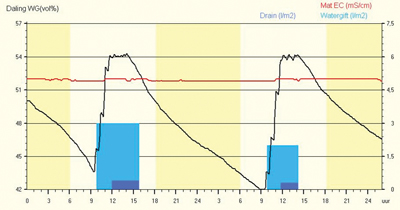

This is demonstrated in practice in Figure 5.0. The start time of irrigation is 3.5 hours after sunrise, allowing slab WC to fall 12 per cent over night, facilitating energy saving measures by limiting greenhouse humidity rise in the morning and providing a strong generative crop reaction. The substrates design enables large irrigation volumes to be applied, indicated by the steep rise in WC. The irrigation efficiency allows EC to be stabilized at 5.0mS and day level WC at 54 per cent – again a generative action and with minimal drain volume (dark blue bar), saving fertilizer.

|

|

| Figure 5.0: The re-saturation and irrigation efficiency of the substrate is clearly linked to the applied volumes of irrigation.

|

|

|

| Figures 4.0d

|

FUTURE ARTICLES

In conclusion, the design features of the substrate impact on its ultimate performance and management in the greenhouse. Understanding these features facilitates specific user advice to be generated by the manufacturer, which in turn allows the grower to get the optimum performance out of crop.

The next article in the series will define the targets and goals for steering the balance in the crop from planting through to final production. ■

|

|

| Figures 4.0e

|

Figures 4.0f

|

Print this page