Canada’s reputation for leading edge greenhouse innovation is well

established, a key factor in the sector’s success in North American

markets.

Canada’s reputation for leading edge greenhouse innovation is well established, a key factor in the sector’s success in North American markets.

|

|

| Consultant Abida Nasreen and Dr. Les Shipp check plants in a screened compartment. Advertisement

|

The Greenhouse and Processing Crops Research Centre in Harrow, Ontario, is contributing significantly to the continued growth of the industry across Canada.

The Centre is the largest greenhouse research facility in North America, and is situated near Leamington, home to the largest concentration of greenhouse vegetable production in North America.

We recently toured the centre, to highlight a few of the projects now underway.

EYEING A NEW STAR AMONG PREDATORY MITES

■ There may be a new star performer among predatory mites.

|

|

| Harrow is doing considerable work with LEDs

|

Amblydromalus limonicus is a new product in Canada, and it’s already making an impression with researchers.

Dr. Les Shipp, a greenhouse entomologist with Agriculture and Agri-Food Canada, is heading research into which predatory mites provides the best early season thrips control in pepper crops.

The team evaluated limonicus along with two more established predators – Neoseiulus cucumeris and Amblyseius swirskii – comparing their predation rates of first instar thrips larvae, the normal prey for these mites.

Limonicus performed a little better than the other two in terms of predation rates, but it is pricier. When growers consider their options, they have to determine what is the most cost-effective control strategy.

The added bonus with limonicus is that it feeds not only on first instar thrips larvae, but also on the second instar larval stage.

Swirskii also feeds on second instar larvae, but not as much as limonicus.

Cucumeris is too small to feed on this larger stage as it would simply be flicked off.

Having a predator that goes after multiple stages is a big plus. If the release timing is a little off and the mite misses its prey stage, it will take much longer to gain control. “However, if they feed on more than one instar, you will get control much faster,” says Shipp.

The researchers are continuing their trials with these mites.

Some mites are also generalist predators and feed on more than one prey. Swirskii is a good example, as it also feeds on immature whitefly

stages. Limonicus is thought to do the same.

This would give growers a little more help in pest control, and would also provide another food source for the predators.

POLLEN AS A SUPPLEMENTAL FOOD SOURCE FOR PREDATORS

■ Some predators feed on pollen, too. “We’ve been looking at using pollen as a supplemental food source,” says Shipp.

Most recently, he’s worked with a pair of cut flower growers who have been placing pollen on cut mum plants to see if it will boost the population levels of predatory mites. “We’re seeing some positive results.”

Pest management research in one sector can be applicable to both industry sectors: ornamental and vegetable crops. There’s a good chance a product or process that works well on vegetable crops, for example, would also apply in ornamentals, with a little fine-tuning.

“Of course, you’d have to work out certain things because you’re dealing with different production systems and plants,” says Shipp.

SUPPLEMENTAL LIGHTING AND PEST MANAGEMENT

■ In another project, Shipp and his colleagues are studying how supplemental lighting affects pest management.

This work is becoming increasingly important as more and more growers are considering year-round production, and that involves either HPS or LED systems, or both.

One project has looked at whitefly control. Lights are on for 16 hours a day. No one really knows what happens to predators or pests under these conditions.

He’s collaborating with colleagues in Finland and Norway. Growers in those countries have been using supplemental lighting for a number of years. “They’re studying these same issues,” says Shipp.

The work at Harrow is in its early stages. It is looking at the effectiveness of Eretmocerus eremicus in controlling whiteflies under supplemental lighting conditions.

Research is also looking at how supplemental lighting affects bees and pollination. If lights come on earlier in the day, it will affect bee movement because they will come out earlier. Things have to be timed just right for the flowers to be open when the bees come out to ensure optimal pollination.

GROWER INITIATED RESEARCH FOCUS

■ Projects are often grower initated, Shipp says. The Centre enjoys a close relationship with the Ontario Greenhouse Vegetable Growers association, among other grower groups.

Consultant Abida Nasreen, for example, had worked on a number of projects with Shipp on a contract funded by the OGVG.

MANY BENEFITS WITH EXTENDED GROWING SEASON

■ Year-round greenhouse vegetable production can help growers gain a competitive edge in the marketplace. Most retailers prefer dealing with a single supplier, someone who can offer consistent, high quality vegetables throughout the year.

|

|

| University of Waterloo co-op students Kathleen Brown and Michael MacLeod are assisting with Dr. Xiuming Hao’s research.

|

Dr. Xiuming Hao is heading a number of projects assisting with that goal. Included is a continuation of a three-year supplemental lighting project, a lighting system comparison study of HPS and plasma light, new greenhouse cover materials, and a unique dehumidification system that will take the stress off summer crops.

This year, the focus is on tomatoes, following last year’s research with cucumbers. This project has funding support from the Ontario Greenhouse Vegetable Growers (OGVG).

Last year’s cucumber trial saw some higher yields. Research colleague Dr. Rong Cao of the Guelph Food Research Centre also found supplemental lighting increased health promoting compounds, such as antioxidants.

In the past, most work with supplemental lighting focused on HPS systems placed above the crop. This is great for providing light to the top of the plant, but the bottom of the plant doesn’t get the same benefit. Providing LED inter-lighting within the canopy can address that challenge, and may improve light use efficiency of the whole plant.

LEDs are also more energy efficient. However, more research is required to find the best ways to grow crops with LED inter-lighting to realize the potential benefits.

This year, he’s experimenting with a variety of lighting combinations. Top HPS systems are operating at either 120 or 200 micromoles/m2/s, while the LEDs are being applied with either one module or two, providing about 40 or 80 micromoles/m2/s inter-lighting. The research will determine which combination works best.

This year’s trials will also study different spectrums of LED inter-lighting, similar to last year, to investigate their impact on health-promoting compounds in tomatoes.

PLASMA LIGHTING TRIALS UNDERWAY

■ Hao is looking for new lighting sources that can help boost production and be more energy efficient.

Relatively new on the market is plasma lighting. It has a full spectrum of light, and is says to be more like sunlight. HPS, on the other hand, has colours more in the orange and red range.

The study is just getting underway. In the growth chamber trials conducted in Europe on transplants, plasma outperformed HPS. However, the growth chamber research featured only single-source lighting – either HPS or plasma systems. In the greenhouse, natural sunlight will also be available to the plants, and it could mean different results because the plants are no longer dependent on a single source of light.

Hao has a greenhouse with HPS on one side, and plasma lighting on the other – with a curtain separating the two zones. The light intensity is the same with both treatments. “If we see any difference between the crops, it will be due to light difference between HPS and plasma.”

COMPARING GREENHOUSE COVER MATERIALS

■ “Cover materials affect light transmission, and we want as much light in the greenhouse as we can get in the winter because it is the limiting factor for crop production. Good light transmission means better plant growth and improved yields and quality.”

It also affects heat loss from the greenhouse. Materials with good insulation values mean reduced heating costs.

This research, funded by the Agricultural Innovation Program, is studying new coverings with light diffusion properties.

Direct light doesn’t offer the best distribution of light within the greenhouse. As well, there is more light at the top of the plant than there is at the bottom.

“With diffused light,” explains Hao, “there is a much more uniform distribution of light within the greenhouse.”

There is also a much improved vertical distribution of light within the crop canopy. “There will be less high temperature stress to the top parts of the plants in the summer.”

While European research is largely looking at diffused glass, the Harrow project is focusing on diffused polyethylene and diffused carbonate.This year’s trial is working with peppers.

NOVEL APPROACH TO DEHUMIDIFICATION CHALLENGE

■ Summer heat stress can be a major problem for growers, and a researcher at Queen’s University may have a solution.

Dr. Stephen Harrison is an expert in liquid dessicant dehumidification systems. Hao teamed with Harrison to tailor the technology for greenhouse applications, and a unit is now being tested at Harrow in a sweet pepper crop.

The goal is to develop a novel greenhouse climate control system for improved energy use efficiency in greenhouse vegetable production. Dehumidification is a key part of this goal.

“If the air is drier,” says Hao, “the plants can transpire more to avoid heat stress. Plant transpiration is a natural air conditioning system.” This project is also partially funded by the OGVG.

GETTING TO THE ROOT OF THE PROBLEM

■ Dr. Ray Cerkauskas is researching a new material that could be used to control rootborne diseases or possibly as a seed treatment.

Cerkauskas, who divides his time between soybean and greenhouse vegetable research, says the new product, in lab tests, is quite effective in the control of soil fungi, even controlling soilborne propagules.

He is now assessing its effectiveness with greenhouse applications.

The liquid formulation of the material is registered in the U.S. for certain field crops.

There is considerable interest in the product, and for good reason. “We’ve found that it is quite effective in controlling, in vitro, a number of pathogens.”

Cerkauskas is looking at a possible project involving rockwool slabs, as one example.

The study is also looking at plant toxicity at various rates of application.

The research team is studying whether the gas emanating from the material could be used to treat seeds that have bacterial canker.

IDENTIFYING PROBLEMS AT A VERY EARLY STAGE

■ Cerkauskas is hoping to continue his thermal imaging work with Dr. Roman Maev, of the nearby Institute for Diagnostic Imaging at the University of Windsor.

Maev is an international leader in thermal imaging technology, with a team of 25 researchers tackling a variety of projects, ranging from the automotive sector to dentisty.

The goal with plants is to develop a system to identify diseases in young plants at the earliest stage possible and well before they’re set out in the greenhouse.

Thermal imaging may provide that solution. The images show a lot of information with a great deal of variability. It’s not just measuring differences in temperature, but the degree of response.

Young plants with diseases don’t always exhibit visible symptoms. By the time they’re in the greenhouse, however, they’ve been handled a number of times by workers, and the inoculum can be readily transmitted.

The focus is on detecting pepino mosaic virus or bacterial canker, but it should be applicable to other viruses.

MORE RESEARCH INTO YELLOW STEM DISEASE

■ Work on getting an early jump on a latent disease is progressing.

|

|

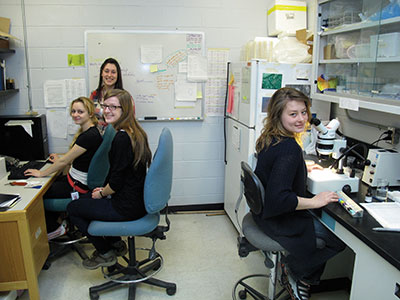

| Co-op students assisting Dr. Les Shipp include Natasha Barlow, Jennifer Pomezanski, Rachel De Jong and Kaitlyn Dawkins.

|

Yellow Stem disease is found in some late-season tomato crops. Caused by Fusarium oxsporum f. sp. radicis-lycospersici (FORL), this latent infection has no symptoms for several months. However, growers face reduced yields once the symptoms do become manifest.

The challenge has been to develop a rapid onset of the symptoms so that biological or other control measures can be tested.

Researchers can inoculate plants with FORL, but they’d then have to wait about nine months for the symptoms to develop. By that time, there may be other issues affecting the plant.

He had hoped to induce symptoms within a few weeks via stressing plants with either hot or cold rootzone conditions, but was unsuccessful.

He now suspects Yellow Stem is age related. The seed and the young plant have resistance, but as the plant moves towards the end of its life cycle, it then becomes susceptible.

Yellow Stem is caused by a fusarium. In the late 1970s and 1980s, it was a problem with greenhouse tomatoes grown in soil. Growers in southwestern Ontario and Ohio were among those affected.

Helping lead much of the research at that time was Dr. Bill Jarvis of the GPCRC, working with colleagues at Ohio State University.

Breeders responded by screening for resistance. And while they were successful with early stage resistance, latter stage susceptibility may not have been screened for, says Cerkauskas.

THE FOCUS IS ON PRACTICAL RESEARCH

■ GPCRC research has always been grower driven, he says. Much of his work is funded by the OGVG.

“We have to be sure the work can be applied in the greenhouse in a practical sense.

He works regularly with Gillian Ferguson, the greenhouse vegetable IPM specialist with the Ontario Ministry of Agriculture, Food and Rural Affairs. “We work closely to formulate a practical means of controlling a disease.”

She will often bring in a sample for him to study.

“The reason we’re able to respond very quickly to industry problems is because we work so closely with OMAFRA.”

Print this page