Features

Crop Culture

Growing Media

Water and irrigation

Breathing oxygen into roots

How much dissolved oxygen is enough? Higher levels could potentially generate greater yields and lower costs.

June 1, 2021 By Bruce Scholten and Dr. Federico Pasini

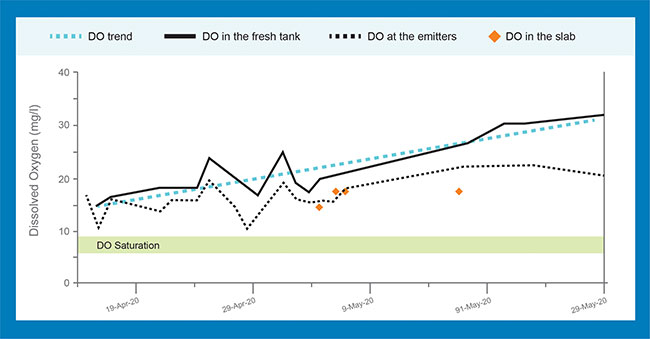

Figure 1. Supersaturated oxygen levels are sustained between 15-20 mg/L over the course of 25 days using nanobubbles. Most aeration achieves 7.5-9 mg/L max. images provided BY Moleaer

Figure 1. Supersaturated oxygen levels are sustained between 15-20 mg/L over the course of 25 days using nanobubbles. Most aeration achieves 7.5-9 mg/L max. images provided BY Moleaer The availability of oxygen in the root zone is a key contributor to the productivity of greenhouse crops. However, it is often overlooked in comparison to water temperature, light intensity, carbon dioxide concentration and other production variables.

Insufficient or inconsistent availability of oxygen in the irrigation water results in suboptimal metabolic rates in root cells. On a cellular level, there is reduced generation of adenosine triphosphate (ATP), the main form of energy used to drive metabolic processes. A lack of dissolved oxygen (DO) concentration in irrigation water is therefore a limiting factor in root cell growth and overall plant growth.

How much dissolved oxygen is enough? It is generally believed in the greenhouse horticulture community that DO concentrations of 4-8 mg/L, typically generated by traditional water aeration systems, are sufficient to ensure adequate plant growth and health. However, research has shown that elevating DO levels to very high levels (18-25 mg/L) provides much higher rates of growth, better plant health and higher yield.

For example, a 2019 study conducted by Delphy Research Institute, a leading horticultural research entity in the Netherlands, confirmed the impact of very high DO levels in achieving more productive greenhouse crops, along with reduced operation and maintenance costs related to other technologies for oxygenation and maintenance of irrigation water quality. Specifically, this study demonstrated how highly elevated, stable DO levels of 18-25 mg/L are associated with the accumulation of respiratory metabolic enzymes that facilitate absorption of micronutrients by root cells, resulting in more ATP production, higher plant growth rates and higher yields. In addition, the presence and properties of the nanobubbles responsible for highly elevated DO levels also reduce the surface tension of the water and increase the “wettability” of surfaces, facilitating more efficient absorption of water from the substrate and transpiration through the leaves.

Overall plant health is also boosted by very high DO concentrations. When water temperatures increase in greenhouse irrigation systems due to warm weather, DO concentration is reduced, which favours the proliferation of undesirable pathogens such as Pythium, as well as reduced nutrient uptake and deterioration of the root zone in the long-term. Very high DO levels prevent the creation of these conditions, preventing pathogen proliferation, promoting the growth of beneficial microbes and reducing the use of disinfection chemicals to little or none.

Driving plant growth

High-quality irrigation water and sustained high levels of dissolved oxygen have proven essential to achieving high rates of nutrient uptake, photosynthetic capacity and cellular energy production, resulting in improved plant resilience and capacity to handle stress. This is because the health and growth rate of plants is directly impacted by the health and development of the root system. The root zone is where the plant regulates its delicate interaction with the growing medium (or directly with irrigation water in hydroponic systems), taking in the nutrients, oxygen and water needed for the production of cellular energy.

In plants, nutrient uptake occurs in two ways, through passive and active mechanisms.

In the first instance, dissolved ions passively migrate into plant root cells by diffusion at a rate proportional to the difference in concentration between the water and the interior of the root cells. No energy is required for this type of nutrient absorption, with nutrients moving from an area of high concentration to an area of low concentration, provided the concentration of nutrients in the substrate is sufficiently high. However, passive nutrient absorption is affected by the nutrient concentration gradient, type of nutrient (e.g. anions/cations, mono-, bi- or tri-valent ions), type of growing medium and the schedule/intensity of the irrigation cycle. As this type of nutrient uptake is obviously limited, plants also have ‘active’ uptake.

In situations where the migration of ions is contrary to the concentration gradient (from low to high), root cells use cellular energy (ATP) to bring nutrients across their membranes. It has now been established that higher DO levels in irrigation water boost plant cell metabolic rates; in root cells, this means more ATP is produced and more nutrients can therefore be absorbed. Conversely, if ATP is limited, root cells are limited in their nutrient uptake, synthesis of hormones and other metabolic processes, which in turn decrease both the rate of root growth and overall plant development.

Favouring beneficial bacteria

Using irrigation water with sustained high levels of DO favours the growth of beneficial bacteria in the root zone. In a highly oxygenated environment, these organisms can then outcompete pathogens such as Pythium, Fusarium spp. and Phytophthora, which all prefer lower oxygen environments. Higher DO levels also result in a reduced release of phenolic compounds produced in cells during low oxygen (anoxic) conditions and that are generally detrimental to the health and growth of the plant. These phenolic compounds can attract pathogens such as Rhizobium rhizogenes to the root surface, causing hairy root disease. In addition, promoting the growth of beneficial microbes improves nitrification in root cells and increases their rate of hormone and enzyme production, all of which aid in enhancing nutrient absorption and use.

Traditional aeration systems cannot generally provide sustainable and efficient production of high DO levels. This is especially true in warm water. As the temperature of water rises, its capacity for holding dissolved oxygen lowers. Growers who need warm water are therefore forced to use costly and environmentally unfriendly disinfection agents to prevent pathogen growth. In some cases when the temperature climbs, growers compensate for the limits of their current aeration system with costly, inefficient water chilling systems.

The availability of novel water aeration methods such as oxygen nanobubble technology is therefore a very exciting development in the greenhouse horticulture sector. Very high DO levels can now be achieved using these systems.

Testing with high dissolved oxygen levels

A study was conducted in 2020 by Nova Crop Control to investigate the effects of high DO levels in the irrigation water of tomato plants. Results confirmed that very high DO levels improved growth rate, crop yield and colouration.

Figure 1 shows supersaturated DO levels achieved over 25 days of nanobubble injection, measured at multiple points. Figure 2 depicts the effect of the super-high DO on Pythium infection level. In this study, yield increased with super-high DO by 11 per cent due to reduced Pythium levels in the water. Fruit weight was also higher by 9 per cent.

Here are other brief summaries from a small sampling of recent studies. In comparison to greenhouse plants receiving untreated water, plants that received nanobubble-treated (NB) super-oxygenated water achieved the following yield increases (among other performance parameters):

- 23 per cent in tomato (2019, Journal of Agricultural and Food Chemistry, China & UK)

- 18 per cent in blueberry (2019, Elemental Foods, Chile)

- 24 per cent in cannabis (2019-2020, Moleaer, Royal Brinkman & Wageningen University, The Netherlands)

- 18 per cent in pepper (2019, Popoyán, Guatemala)

- 14 per cent in strawberry (2020, Delphy Research Institute, The Netherlands)

Sustaining high DO levels

Oxygen supersaturation in greenhouse irrigation water has been shown to improve root development, plant health and overall crop yield. Furthermore, very high DO levels also prevent the proliferation of pathogens in a cost-effective, simple and environmentally friendly manner. As a result, little or no chemical oxidizers are required as the high DO has created unfavourable conditions for the growth of pathogens.

One way to create a high DO environment is by using nanobubbles. Ranging from 50-150 nm, nanobubbles remain buoyant and easily circulate throughout the water system. This, together with their high surface area, ensures high gas-transfer efficiency, independent of water depth, contrary to what occurs with most conventional aeration systems.

A negatively charged surface keeps the nanobubbles stable in bulk solution where they provide an important buffering effect, much like a battery reserve of oxygen that ensures long-lasting interactions between gas and water, as well as a constant release of oxygen over time. This reduces the amount of oxygen needed in an irrigation water aeration system.

The negative surface charge prevents bubble coalescence and enables long-term bubble stability. In addition, negatively-charged nanobubbles repel nutrient ions that are positively-charged in an irrigation system, promoting their movement towards plant roots and subsequent absorption by plant root cells.

Lastly, the high internal pressure of nanobubbles favours the release of reactive oxygen species (ROS) when the bubble finally collapses. This provides chemical-free oxidation that reduces and inhibits the growth of pathogens and algae. Nanobubbles can aid in the removal and prevention of biofilm from developing on pipe surfaces, with biofilm being an area where pathogens can harbour.Most importantly, it has the potential to lower water treatment costs for greenhouse businesses.

Bruce Scholten, MBA, is co-founder and chief technology officer, and Federico Pasini, PhD, is an application engineer at Moleaer, a nanobubble technology supplier. They can be reached at federico@moleaer.com or info@moleaer.com.

Print this page