If you want to see what a greenhouse of the future will contain, take a

tour of the Greenhouse and Processing Crops Research Centre in Harrow,

Ontario.

If you want to see what a greenhouse of the future will contain, take a tour of the Greenhouse and Processing Crops Research Centre in Harrow, Ontario.

|

|

| Dr. Kwang-Ho Kim is studying the interaction of biocontrols with microbial control agents. Advertisement

|

Research being done there today will soon be standard production practices in greenhouses – both ornamental and vegetable – across Canada. During our mid-April visit, projects ranged from enhanced biocontrol strategies, to advanced energy conservation strategies and leading edge disease prevention trials, to name a few. Harrow offers the industry’s very own crystal ball into the future of greenhouse production.

The GPCRC is the largest greenhouse vegetable research facility in North America.

BOOSTING BIOCONTROL EFFICACY AND EFFICIENCY

■ Dr. Les Shipp is overseeing a number of projects this spring, including a pair focusing on biocontrol effectiveness.

|

|

| Ladybird beetle larvae.

|

In one study, consultant Abida Nasreen is working on a contract funded by the Ontario Greenhouse Vegetable Growers to determine whether “freshness” is a major factor in parasitoid effectiveness.

There are times when predators have to be stored for a time before being released, and growers want to know the effect this has on efficacy. The study is looking at Encarsia formosa and Eretmocerus eremicus, two widely used whitefly parasitoids.

“There has been anecdotal evidence with some growers who say a fresher product is a better product,” says Shipp. They say that compared to stored parasitoids, fewer “fresh” parasitoids are required to do the same job.

“This would be important information for growers,” says Shipp. Given the size of acreages, there would be substantial savings if growers can reduce the number of release points, or the numbers of wasps released.

“Growers appreciate any help we can give them in reducing their costs and improving their pest control measures.”

It’s an eight-month study, with work now in the lab. The most successful treatments will then be taken to greenhouse trials.

There are three components to the lab research.

- Emergence – how many predators emerge from the fresh supply and how many from the stored samples, and do they all emerge at once?

- Flight capability – how well do they disperse and how good are they at foraging.

- Parasitism efficacy – the number of parasitized whitely scales are counted.

INTERACTION OF BIOCONTROLS WITH MICROBIAL AGENTS

■ In a second project, Dr. Kwang-Ho Kim, a visiting scientist from the National Academy of Agricultural Sciences (NAAS) in South Korea, is studying the interaction of biocontrols with microbial control agents.

|

|

| Abida Nasreen checking parasitism rates… | |

|

|

| …looking over the setup in a flight chamber.

|

In the study, the predators (ladybird beetles) have a choice of going to Chinese cabbage plants sprayed with Beauvaria bassiana (the microbial fungus), or to plants that have not been sprayed.

In early tests, the beetles have tended to avoid the treated plants by a wide margin. And this is good news for growers, as they will get better crop coverage when using both controls.

The controls would complement each other when applied together. And that’s important in light of related biocontrol research now underway in South Korea at the NAAS. Dr. Jeong Jun Kim has been using ladybird beetles and lacewings as vectors of microbials in vegetable crops.

GPCRC will welcome Kim later this year as a visiting scientist.

“Not only do they control pests themselves, because they’re predators, but they will also bring their microbial agent with them, and this will affect insect populations, too,” Shipp explains.

The concept is similar to the bee vectoring work done over the past dozen years or so at Harrow, in which bees departing the hive were dusted with inoculum to disperse as they pollinated the crop. The results were quite impessive.

GETTING AN EARLY START ON A LATENT DISEASE

■ Dr. Ray Cerkauskas has a number of disease control projects underway, all funded by the OGVG.

|

|

| Craig MacNair, a University of Western Ontario co-op student, looks over tomato plants infected with botrytis. The research is looking at a label expansion for PreStop. Project funding was provided by OGVG, MGS and Verdera Oy.

|

In one project, he and his colleagues are studying Yellow Stem disease found in some late-season tomato crops.

The disease is caused by Fusarium oxysporum f. sp. radicis-lycopersici. It’s a latent infection in which symptoms don’t show up for several months, leaving growers with reduced yields when the symptoms become more manifest.

Cerkauskas is hoping to find a control agent or agents – biologicals, fungicides and/or reduced risk materials – to nip the problem in the bud early in the crop cycle. But it won’t be easy, given how long the problem takes to evolve.

“It’s hard to evaluate the efficacy of any control measure if it takes nine or 10 months for symptoms to show up.”

He’s been trying to enhance the disease response, to get sufficent disease expression within three or four weeks so he can monitor the effectiveness of potential early controls.

One area of study is in changing the rootzone environment. He’s placed rockwool slabs with rockwool blocks containing infected plants atop an acrylic plank filled with water tubes. He can run either hot or cold water through the tubes.

The first trial involved heating the rootzone. However, the heated rootzone didn’t accelerate the development of the disease.

He’s now looking at cooling the rootzone, and the results will be known soon.

“If we don’t get fast symptom response,” he notes, “we know it is not environmental stress in the rootzone (that leads to disease symptoms).”

The other possibility is that Yellow Stem is associated with the physiology of the plant – the older it gets, the more susceptible it becomes to the disease.

“My main objective is to get control,” he explains, “but we first have to get disease symptoms in three to four weeks.”

FUSARIUM STEM AND ROOT ROT IN CUCUMBERS

■ Fusarium stem and root rot caused by Fusarium oxysporum f. sp. radicis-cucumerinum is another serious disease for growers, and Cerkauskas is hoping that combining a pair of controls will be more effective. Previous work about a decade ago found that disease symptoms could be reduced with the application of potassium silicate.

The research is now looking at adding reduced risk materials. An earlier trial was not as effective as hoped, but that was with a single application of the reduced risk material. The next attempt will involve a weekly application.

NEW CONTROL FOR CUCUMBER POWDERY MILDEW ‘IN PIPELINE’

■ Cucumber, tomato, and pepper powdery mildews are major problems for growers, and there are a couple of good controls to keep things in check.

|

|

| Dr. Xiuming Hao, and University of Waterloo co-op students Jingjing Chen and Michael Wong, with a trial for rootzone and air temperature treatments for mums. | |

|

|

| Research technician Celeste Little, with poinsettias used in a growth chamber trial on air temperatures.

|

Because cucumbers grow so quickly, it’s especially important to have good control. However, a degree of resistance to one of the fungicides has developed in the cucumber powdery mildew fungus.

Thankfully, Cerkauskas and his colleagues have been working on the problem, and there are some remedies “in the pipeline” being considered for registration.

There are also some other materials being evaluated that have promise. That’s good news by itself; the better news is that they have a multi-site mode of action, meaning there will be less possibility of resistance that can develop.

If there is only one site being attacked by a fungicide, it’s easy for some of the spores – among the billions – to change, and the metabolism of the fungus is altered and overcomes that attack point… leading to resistance.

However, if there are many sites attacked by the control agent, it’s much harder for resistance to develop. “For example,” says Cerkauskas, “you don’t have resistance in cucumber powdery mildew to sulphur anywhere in the world.”

ELIMINATING PROBLEMS AT PROPAGATION STAGE

■ Detecting disease threats is not easy; symptoms with new plants may take weeks – in some cases, months – to arise. And once active, they’re easy to spread via routine crop maintenance and plant handling.

But what if you can identify those plants before they’re set out? What if propagators had new technology and software to flush out the problem plants before they’re shipped?

The solution might be a click away.

Cerkauskas has been working with Dr. Roman Maev and his student Dmitry Gavrilov, both of the Department of Physics at the University of Windsor, and OMAFRA IPM specialist Gillian Ferguson on a thermal imaging project.

Maev is a world leader in thermal imaging technology, with a team of 25 researchers tackling a variety of projects.

The camera can detect temperature differences of a tenth of a degree. “A virus infected plant,” notes Cerkauskas, “has a lot of virus particles, so its physiology is altered, its metabolism changed. You should be able to detect that.”

The problem, however, is that there are a lot of variations: what separates the good from the diseased plants, and can the technology consistently find the infected plants in their propagation trays?

The images show a lot of information, with a great deal of variabilty. The sophisticated software takes hundreds of data values every second. It’s not just measuring the temperature, but the degree of response. “We’re looking for a differential response between healthy and infected plants.”

Young plants don’t show visible symptoms; it’s later in the crop cycle that the problems will emerge. “Once that happens, they’re already in the greenhouse.” They could have been in the greenhouse for months, and handled frequently by employees.

“Plants with latent infection, with no visible symptoms, are sources of inoculum that are readily transmitted once the plants are touched. It would be better to identify these plants and discard them before they leave the propagator.”

The research is currently looking at pepino mosaic virus, but it should be applicable to other viruses.

ENERGY EFFICIENCY HIKED FOR TOMATO CROPS

■ A major four-year national research project to improve energy use in tomato crops, led by Dr. Xiuming Hao, has wrapped up with impressive results.

The project was launched in 2008. Also involved were AgCanada colleagues Dr. David Ehret of the Pacific Agriculture Research Centre, Dr. Martine Dorais at Laval University, and Dr. Tom Papadopoulos of the Harrow station.

The goal was to develop and evaluate plant-base:

- Dynamic temperature integration (TI) climate control technology.

- Lighting strategies.

- Automatic plant growth monitoring technology.

- New fertigation strategies to improve energy efficiency in greenhouse crop production.

“We found that with a pre-night or pre-morning temperature drop you can change the plant growth balance and shift production earlier,” says Hao.

Overall yields did not increase in tomatoes. But having the spike in earlier production means growers can capitalize on the higher early-season prices. The supply of tomatoes is lower at this time, resulting in the higher market prices.

Just as importantly, this temperature strategy reduces energy usage per unit of produce.

Temperature integration involves applying higher air temperatures when heating costs are lower (warmer outside conditions), and cooler temperatures when heating costs would be higher because of colder outside conditions. The same 24-hour average temperature target or long term target average temperature is maintained to ensure optimal crop response.

Since the fruit has a smaller surface area per unit of volume in comparison to the leaves, using temperature integration strategies with a pre-night or pre-morning temperature drop leads to higher fruit temperatures compared to the leaves. This has the effect of changing the plant growth balance in favour of more fruit production early in the season.

Essential to this strategy is the use of a grow pipe in the crop canopy to prevent humidity and condensation problems.

The researchers found TI with pre-night and pre-morning temperature drops resulted in energy savings of three to five per cent. For example, growers would drop temperatures in pre-morning hours when it’s colder outside, a time when they would normally have used more energy to maintain temperatures.

“They could do the pre-night drop in March, and the pre-morning drop in April.” Temperatures need to be maintained at safe levels during the drop for the crop.

Applying TI with pre-night and pre-morning temperature drops to cucumbers was also successful. While early yields increased, energy usage was about the same. “But overall energy efficiency was still increased because overall yields were increased in cucumbers.”

ENERGY USAGE RESEARCH WITH ORNAMENTALS

■ It’s not all vegetable research at the station. Several ornamental projects have been undertaken over the past several years.

|

|

| It’s been another busy greenhouse construction season in the Leamington/Kingsville region.

|

Hao, for example, has been working with the Canadian Ornamental Horticulture Research and Innovation Cluster.

The cluster also includes the University of Guelph and OMAFRA.

Among projects, this team is looking at improved energy efficiency for two major potted crops in Canada – poinsettias and mums.

The goal is to develop dynamic greenhouse heating and climate control strategies and technologies to conserve energy in greenhouse ornamental crop production, while ensuring proper scheduling and plant quality for the market.

“With flowers, you have to ship right on time,” notes Hao.

While the same basic temperature integration strategies used for tomatoes and cucumbers were applied, the goal was not to achieve earlier flowering, but to produce more compact plants.

Growers usually use plant growth regulators to keep plants more compact.

However, with the new temperature strategies, researchers hope to change the morphology of the plant to make it more compact.

Applying an early morning temperature drop (6 to 9 a.m.) to poinsettias resulted in shorter internodes, making it a more compact plant. There was no change in total biomass compared to control plants.

Researchers are also identifying optimum rootzone heating temperatures to be used in conjunction with the new dynamic temperature control strategies.

Many potted plant growers make use of floor or bench heating systems. With such heating applied to the rootzone, air temperatures can remain a little cooler because floor heating can effectively transfer heat to the plant, allowing for a warmer plant even if the air temperature is maintained at the same level. It is the plant temperature that determines the growth and development rates of the plant.

During an early morning temperature drop, growers could apply slightly higher rootzone temperatures. However, growers have to be careful not to let rootzone heating get too high or they will risk damaging the roots.

The research also involved post-harvest studies to ensure quality is not affected.

MINI-CUCUMBER PRODUCTION WITH SUPPLEMENTAL LIGHTING

■ Hao has also started a three-year project, with the fund support from the Ontario Greenhouse Vegetable Growers (OGVG), to develop a sustainable year-round mini-cucumber production system with high energy use efficiency.

Also involved are Dr. Xiang Chen of the University of Windsor, Dr. Rong Cao of the Guelph Food Research Centre, and Philips Lighting Canada.

HPS light bulbs are quite hot, and HPS light fixtures must be positioned well above the crop to avoid damaging the plants.

However, LEDs can be utiliized for interlighting within the crop canopy. The bonus is that their waste heat – comparable to grow pipes – can be used by the plants. (Grow pipes can increase mini-cucumber yields by between five and eight per cent.) “You can utilize both the light and the waste heat.”

This is a good way to improve overall energy efficiency.

There has been research elsewhere showing that certain LED wavelengths can increase ascorbic acid levels in lettuce. “We will look at different spectrums of LED lighting to see if we can increase the antioxidant content in cucumber fruit.”

APPLYING A NOVEL DEHUMIDIFICATION SYSTEM IN GREENHOUSES

■ Heat is a major problem for many greenhouse crops each summer, and Hao is working with Dr. Stephen Harrison from Queen’s University on a liquid dessicant dehumidification system tailored for greenhouse applications. The project is also partially funded by OGVG.

The goal is to develop a novel greenhouse climate control system for improving energy use efficiency in greenhouse vegetable production.

Dehumidification is important. “If the air is drier, the plants can transpire more to avoid heat stress.”

And with drier conditions, it also becomes feasible for the growers to apply the right amount of misting to cool the greenhouse air.

The system is being tested at Queen’s, and will be used on a tomato crop at Harrow this summer.

ANOTHER BUSY SEASON FOR VEGETABLE EXPANSION

■ Despite the pressures of a strong dollar, the Ontario greenhouse vegetable sector remains quite busy, with a number of expansions underway.

And this is after a strong year last year in terms of new construction.

|

|

|

|

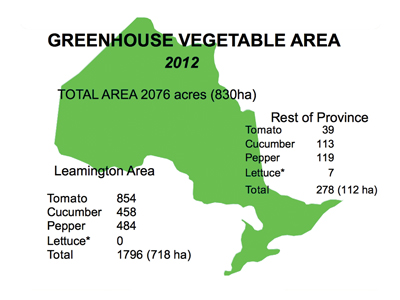

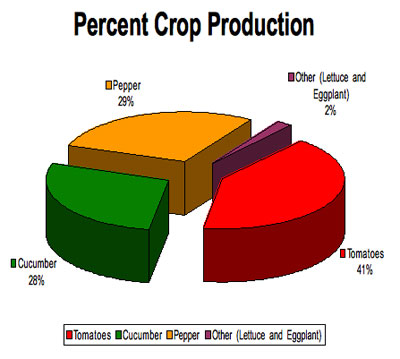

| Charts courtesy omafra

|

According to the Ontario Greenhouse Vegetable Growers association, some 148 acres were added in 2011, bringing total acreage to 2,076 acres.

The greenhouse vegetable sector employs some 10,000 people.

There are 223 greenhouse vegetable operations in the province, with an average size of just over nine acres. The smallest is just under an acre, while the largest is some 126 acres.

This year, more expansion is underway with about 200 acres being constructed.

Shalin Khosla, the greenhouse vegetable specialist with the Ontario Ministry of Agriculture, Food and Rural Affairs, says most of the construction last year was in glass. Much of the new acreage was in peppers, followed by tomatoes and cucumbers.

“The sector is continuing to move forward,” he notes. “We will have about 2,200 acres in the province once the dust settles this year.”

The renewed interest in glass is due to the fact glass prices have dropped in recent years, while plastic prices has risen. “The price difference isn’t as large as it used to be.”

The new projects have been in the 20- to 22-feet tall range, with some up to 25-feet in height.

“The reason for the taller greenhouses is for improved climate management within the crop,”

he says. The new greenhouses are about the same height as those now being built in Europe.

For the taller crops, such as tomatoes and peppers, you need the extra height above the canopy to provide a buffer to outside conditions. “The taller the greenhouse, the better the environment. Especially if there is space between the top of the plant and the outside.”

The interest in specialty crops, including smaller tomatoes, different colours of peppers, and mini-cucumbers, is continuing by growers.

Assisting the sector has been relatively low natural gas prices. “The interest in alternative fuels is not as strong as it had been in other years,” says Khosla.

The sector is committed to environmentally sustainability, including capturing rainwater and water recycling, in addition to the recycling of materials such as plastic.

There is also more interest in light diffusion in coverings. The new materials both glass and plastic provide better light dispersal in the crop.

The farmgate value of the Ontario crops rose to $698 million in 2011, up from $641 million in 2010, according to Statistics Canada.

More than 435 million pounds of greenhouse tomatoes are produced in the province, along with 130 million pounds of peppers, and some 270 million English cucumbers, according to the OGVG.

Print this page