Features

Structures & Equipment

Water and irrigation

Fertigation Applications for Hydroponics

The system can be designed for any size of greenhouse to accommodate multiple collection tanks.

September 16, 2015 By Eric Labbate

The system can be designed for any size of greenhouse operation.

The system can be designed for any size of greenhouse operation. October 2015 – Today many growers produce high value hydroponic crops in greenhouses and they have developed a growing science for vegetables and flower crops under protected cover.

Let’s go back when drip irrigation was first introduced with simple irrigation time clocks. This was a big step forward for growers as they could semi-automate their irrigation systems. Later, venturi injectors were introduced as a means to draw dissolved fertilizers into the irrigation water line.

As time went on, injectors were introduced and through the use of EC and pH meters, we could monitor total fertilizers being fed to the crop. By controlling the pH of the irrigation water, it would keep irrigation lines and drip emitters clean and free from clogging.

But more importantly, we learned that by keeping the pH more neutral, to approximately 5.5 pH, the plants would take up more water and fertilizer nutrients, resulting in better yields.

As we got more creative, growers were introduced to more sophisticated fertilizer injectors to inject directly into pressurized irrigation water lines.

New software programs were introduced to control the amount of fertilizers being delivered to the irrigation water. These programs would allow you to evenly draw fertilizers from an A-B stock tank and control overall EC with a third venturi injector for the acid tank for pH control.

In an A-B tank system you have two mixed fertilizer solutions with four main fertilizers, calcium nitrate, potassium sulfate, magnesium sulfate and mono potassium phosphate. Iron is then added to one tank and micronutrients are added to the second tank. In some cases other fertilizer mixes are used as well.

The A-B tank concept may work fine for general feeding purposes, as you draw two main solutions to the irrigation water tank with an overall EC measurement for a safeguard.

This concept has some drawbacks. Measuring the EC will only tell you the total dissolved fertilizer in the water, but what it does not tell you is how much calcium, nitrogen, potassium, magnesium and phosphorus are delivered to the crop. Unless you start doing some complex calculations to see what you have mixed in your stock tanks and how much fertilizers you are siphoning into the irrigation water, it is difficult to determine your feed formula. As well, there is poor control over the delivery of iron and micronutrients since they are pre-mixed in A-B batch tanks.

So if you end up with high levels of any fertilizer element in the irrigation water, it is hard to re-adjust your solutions since they are already mixed.

Many growers today are recycling irrigation wastewater and are finding it difficult to balance their fertilizer elements using the A-B tank system. Periodically they have to dump their collected water because of an undesirable buildup of certain fertilizer elements.

Now let’s look at this in a different way. Instead of using A-B premixed solutions, we can use positive displacement injectors to deliver each fertilizer solution measured in milliliters per pulse. You can precisely dispense each one of the fertilizer solutions directly into a pressured water line with a closed blending tank (no open tank like an A-B tank system).

With six injectors connected to six fertilizer tanks, we can mix any feed formulas injected directly into the pressurized irrigation water line and easily control each fertilizer dispensed using the following fertilizer stocks:

- Calcium nitrate.

- Potassium sulfate.

- Magnesium sulfate.

- Mono potassium phosphate.

- Iron.

- Micronutrients.

With the use of portable single ion meters, we can test the water sample on site. If you discover you are low or high on any of the main fertilizer elements, you simply readjust the volume of fertilizer displacement for that specific injector.

From the following calculations we can determine how many PPM of each fertilizer nutrient we are delivering to the plants.

- Feed formulas calculations: Some fertilizer feeding programs are specified in PPM or milligrams/per litre of water. This terminology simply means “Parts Per Million.” In a mixed fertilizer solution, “one PPM” of a certain nutrient such as nitrogen (No3) simply means that there is one part of nitrogen in one million parts of water by weight.

- PPM calculations: You can use this formula to calculate the PPM for each element in your fertilizer stock solutions. (Kilograms of fertilizer / Litres of water in solution x grade of fertilizer x 10 = PPM (Kg / Litres Water x Grade x 10 = PPM).

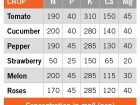

- Nutrient Recommendations for Various Crops (proportional approach).

Why is it so critical to precisely control the fertilizers in the recycled irrigation water?

First, all you can feed your plants is what they need – no more, no less – at any given time throughout the growth stages. Second, you will save substantially on water and fertilizer costs. Third, in many regions it has become mandatory for growers to install closed loop water recycling system for greenhouse irrigation waste water.

In closed loop system, it is important to know what levels of each fertilizer element is injected in the water so that you do not have any buildup of undesirable fertilizer elements in your return water.

You need to know what fertilizer element is making up your total EC. The strategy is to feed plants what they need during their growth cycle – no more and no less.

Now let me explain a bit about the irrigation wastewater diagram.

We start with water collection in the greenhouse and sending it to an underground tank (or under benches). We pump the water through a five-micron MicroZ automatic backwash media filter and store it in the collected water tank.

Water level meters monitor the volume of water in the tank and start and stop the pump as needed. (Meters can display the levels in gallons, litres or as a percentage of tank volume.) The water is fed though an ozone water sterilizing system and then stored in the treated (sterilized) water tank.

Ozone sterilization is a must for water recycling systems and is crucial for bacteria and algae control. But we will leave this topic for another feature!

On the fresh water input side, we start with a water source. It can be municipal water, well water, pond water or rainwater. Fresh water is pumped through a five-micron MicroZ automatic backwash filter and stored in a tank. If the water has bacteria and/or algae, it can also be also sterilized with the ozone system before it is stored in the freshwater tank.

If the source water is high in certain elements such as iron, manganese, sulphur, etc., we can install a Filox media in the filter to remove these elements. If the water is really hard with high levels of unwanted elements, then an RO system can be installed to clean it up. Again, water level meters take care of the pump control on each tank. At this point we have collected, filtered and sterilized irrigation wastewater and stored it. We have also filtered and stored the fresh water.

Now the tricky part begins. We need to look at the EC levels of the collected water and re-blend this with fresh water to lower the EC to an acceptable level. In many cases, the EC of the collected water is much higher than what we need. So using a mixing valve with an EC controller allows growers to mix fresh water with recycled water to lower the EC to desired levels.

For example, if the return water has an EC of 4,000 Us/cm, then this has to be diluted down to say 1,500 Us/cm. If the EC level is set at 2,500 Us/cm, the fertigation control program will make up the difference. From here, the control program on the Fertigation ManagerTM manages the process of delivering the proper fertilizer mixing and sends it to each irrigation zone.

The system displays water flow, EC, pH, and EC of the return water. Data logging records what triggered the irrigation, time, solar level, moisture sensors or VPD. It also logs start time and stop time, litres of water applied per zone, what each fertilizers dispensed per zone, and much more.

The closed loop recycling system (see the diagram in the web version of this story at greenhousecanada.com) has proven to save growers from 35 per cent to 40 per cent on water and fertilizer costs. The system can be designed for any size of greenhouse operation to accommodate multiple collection tanks and manage different feed formulas for each irrigation zone.

This concept is a win-win situation because of the fertilizer and water savings to the grower and meeting provincial requirements at the same time with “zero” runoff.

Eric Labbate is the CEO of Climate Control Systems Inc., which has been manufacturing greenhouse automation systems for climate management, fertigation management, and ozone water treatment systems since 1985.

Print this page